Electric pile of redox flow battery

A liquid flow battery and flow battery technology, applied in the direction of fuel cells, regenerative fuel cells, fuel cell grouping, etc., can solve the problems of high sealing cost and complex structure, reduce the number of parts, easy to operate and assemble, and reduce the thickness of the battery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

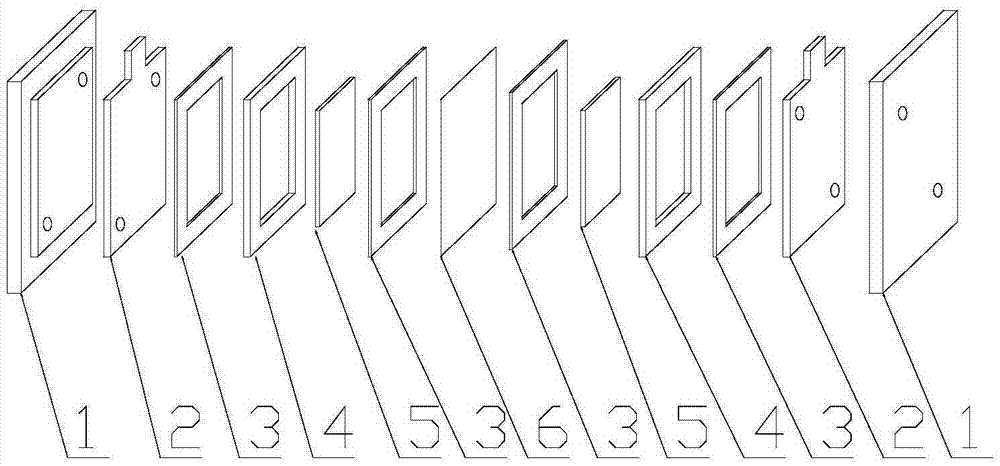

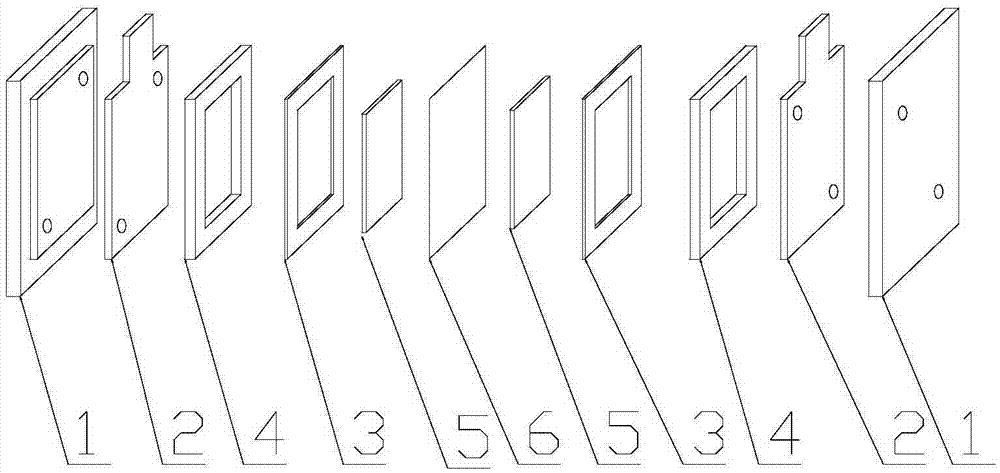

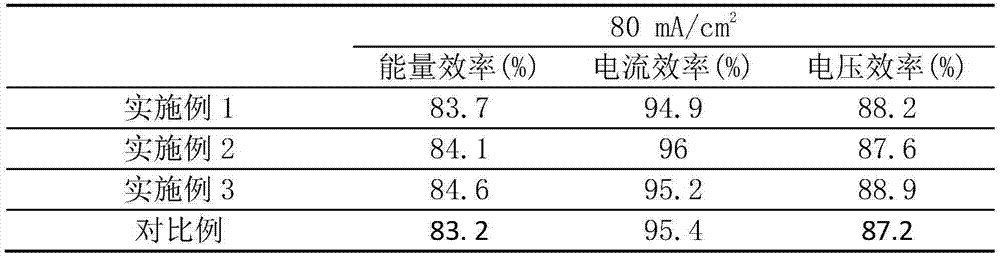

Embodiment 1

[0020] Select a conductive fluororubber plate with a conductivity of 20S / cm as the bipolar plate, wherein the conductive filler is graphite powder, the degree of graphitization is 97%, and the mass ratio is 60%; the rubber component is fluororubber, and the mass ratio is 40% . according to figure 2 The structure shown is assembled into an all-vanadium flow energy storage single cell, in which the electrode frame 4 is 3 mm thick, the electrode 5 is 5 mm thick carbon felt, and the gasket 3 is 0.5 mm thick fluororubber. As shown in Table 1, using the all-vanadium redox flow cell of the present invention, the current density is 80mA / cm 2 , the voltage efficiency and energy efficiency were 88.2% and 83.7%, respectively, which were improved compared with the cell efficiency in the comparative example.

Embodiment 2

[0024] Select a conductive EPDM plate with a conductivity of 10S / cm as the bipolar plate, wherein the conductive filler is carbon black, the degree of graphitization is 60%, and the mass ratio is 30%; the rubber component is EPDM rubber , the mass ratio is 70%. according to figure 2 The structure shown is assembled into an all-vanadium flow energy storage single cell, in which the electrode frame 4 is 3 mm thick, the electrode 5 is 5 mm thick carbon felt, and the gasket 3 is 0.5 mm thick fluororubber. As shown in Table 1, using the all-vanadium redox flow cell of the present invention, the current density is 80mA / cm 2 , the voltage efficiency and energy efficiency were 87.6% and 84.1% respectively, which was improved compared with the cell efficiency in the comparative example.

Embodiment 3

[0026] A conductive polyolefin elastomer plate with a conductivity of 50 S / cm is selected as a bipolar plate, wherein the conductive filler is graphite powder and carbon black, and the mass ratio is 40% and 20% respectively; the polymer matrix component is polyolefin elastomer , the mass ratio is 40%. according to figure 2 The structure shown is assembled into an all-vanadium flow energy storage single cell, in which the electrode frame 4 is 3 mm thick, the electrode 5 is 5 mm thick carbon felt, and the gasket 3 is 0.5 mm thick fluororubber. As shown in Table 1, using the all-vanadium redox flow cell of the present invention, the current density is 80mA / cm 2 , the voltage efficiency and energy efficiency were 88.9% and 84.6% respectively, which was improved compared with the cell efficiency in the comparative example.

[0027] Table 1 The battery efficiency of the all-vanadium flow energy storage single battery at different current densities when the battery structure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com