Solar battery back plate

A solar cell and backplane technology, applied in the field of solar cells, can solve problems such as low reflectivity, yellowing and brittleness, and high heat generation, and achieve good heat dissipation, improved module power, and good long-term aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

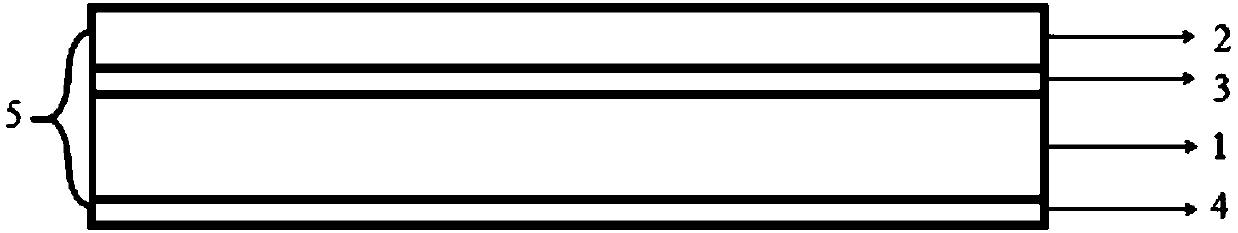

[0023] refer to figure 1 , a solar battery back sheet, comprising a PET base layer 1, a weather-resistant film layer 2, a transparent adhesive layer 3 and an adhesive layer 4 for bonding with an encapsulation adhesive film;

[0024] The above-mentioned PET matrix layer 1 provided by the present invention is a highly reflective foamed polyethylene terephthalate film with a thickness of 50 to 500 microns, and a specific thickness of 250 microns; the weather-resistant film layer 2 is a weather-resistant polyethylene terephthalate film. One of ethylene glycol formate or polyvinylidene fluoride film, with a thickness of 20-50 microns, specifically 22.5 microns; transparent adhesive 3 is a transparent polyester adhesive, with a thickness of 5-30 microns , the specific thickness is 10 microns; the adhesive layer 4 that is bonded to the encapsulation film includes organic resin, curing agent, and inorganic seasoning, and its thickness is 1-30 microns, preferably 5 microns. The organi...

Embodiment 2

[0028] refer to figure 1 , a solar battery back sheet, comprising a PET base layer 1, a weather-resistant film layer 2, a transparent adhesive layer 3 and an adhesive layer 4 for bonding with an encapsulation adhesive film;

[0029] The above-mentioned PET matrix layer 1 provided by the present invention is a highly reflective foamed polyethylene terephthalate film, with a thickness of 50 to 1000 microns, and a specific thickness of 150 microns; the weather-resistant film layer 2 is a weather-resistant polyethylene terephthalate film. One of ethylene glycol formate or polyvinylidene fluoride film, with a thickness of 20-50 microns, specifically 22.5 microns; transparent adhesive 3 is a transparent polyester adhesive with a thickness of 5-30 microns micron, the specific thickness is 10 microns; the bonding layer 4 which is bonded to the encapsulation film includes organic resin, curing agent, and inorganic seasoning, and its thickness is 1-30 microns, preferably 5 microns. The...

Embodiment 3

[0032] refer to figure 1 , a solar battery back sheet, comprising a PET base layer 1, a weather-resistant film layer 2, a transparent adhesive layer 3 and an adhesive layer 4 for bonding with an encapsulation adhesive film;

[0033] The above-mentioned PET matrix layer 1 provided by the present invention is a highly reflective foamed polyethylene terephthalate film with a thickness of 50 to 1000 microns, and a specific thickness of 125 microns; the weather-resistant film layer 2 is a weather-resistant polyethylene terephthalate film. One of ethylene glycol formate or polyvinylidene fluoride film, with a thickness of 20-50 microns, specifically 38 microns; transparent adhesive 3 is a transparent polyester adhesive with a thickness of 5-30 microns micron, the specific thickness is 10 microns; the bonding layer 4 which is bonded to the encapsulation film includes organic resin, curing agent, and inorganic seasoning, and its thickness is 1-30 microns, preferably 5 microns. The or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com