Method for measuring service life of cutting tool, control apparatus and system thereof

A cutting tool and control device technology, which is applied in the field of measuring the service life of cutting tools, can solve the problems such as the use of existing information of CNC machine tools, and achieve the effect of reducing production cost and increasing production volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, the method, control device and system for measuring the service life of a cutting tool of the present invention will be described in detail with reference to the accompanying drawings.

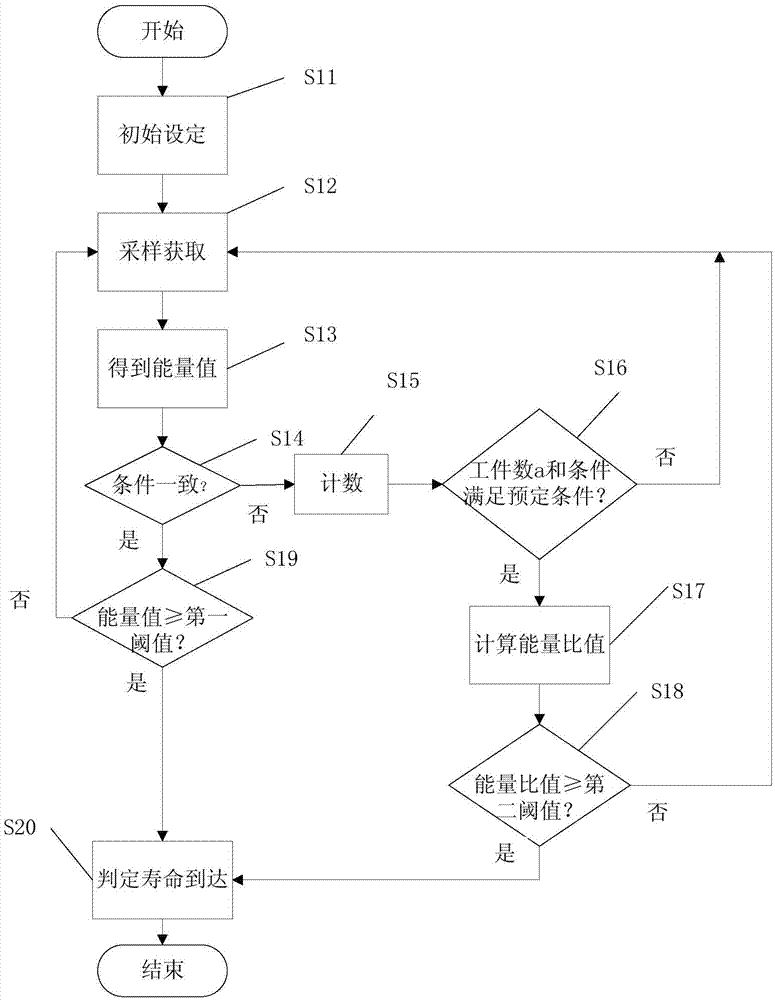

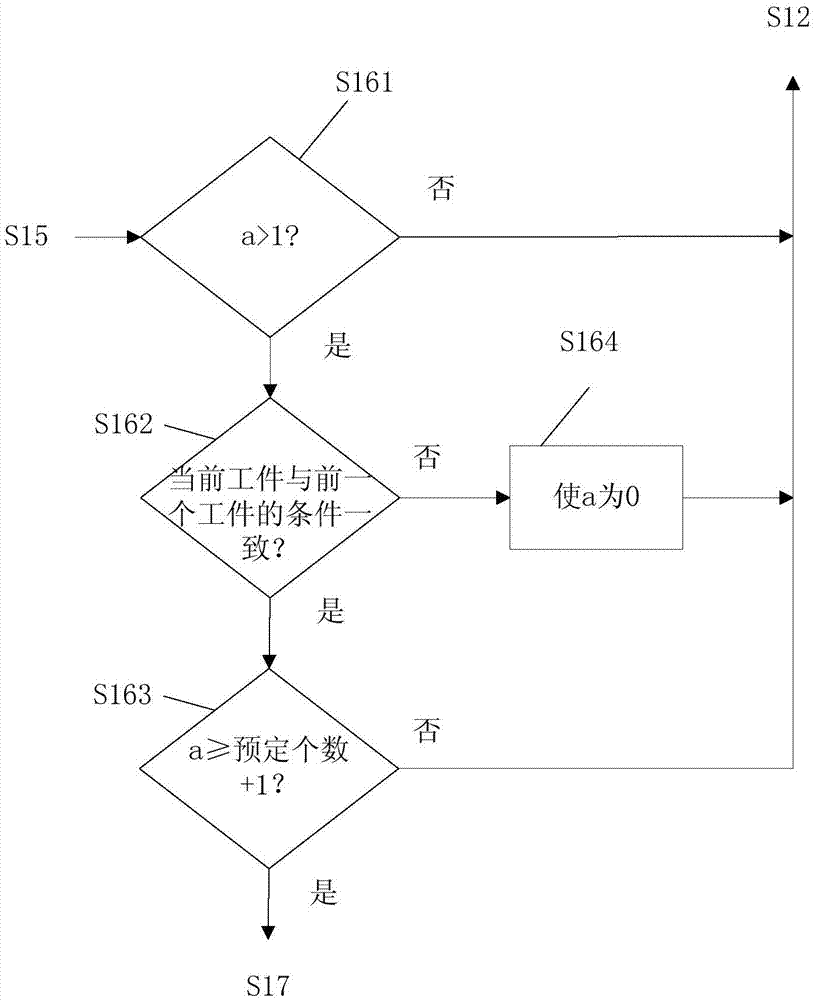

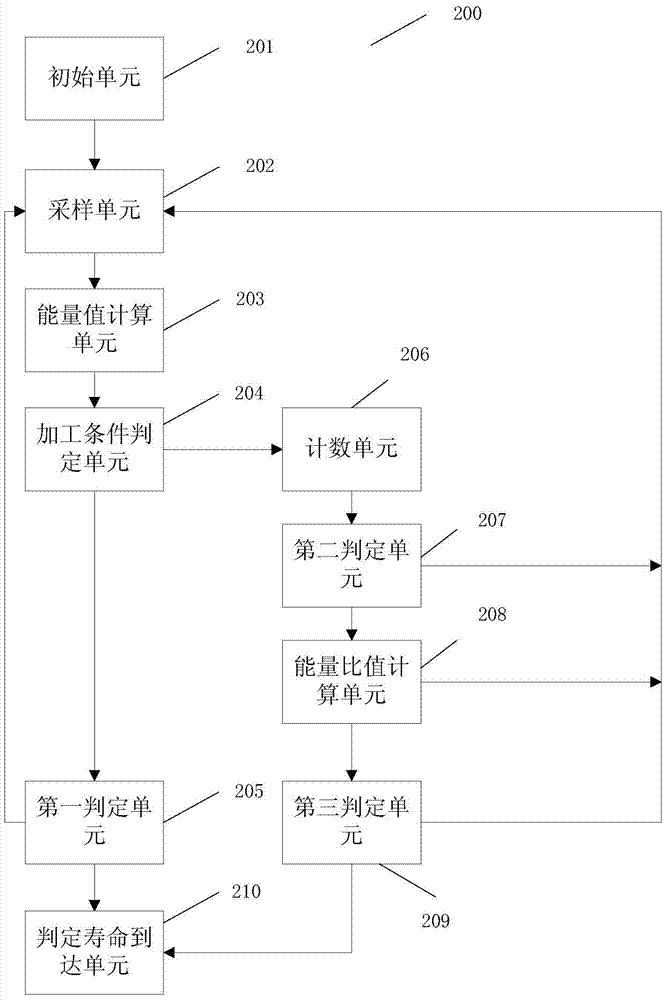

[0085] Figure 1Ais a flowchart of a method for measuring the service life of a cutting tool according to an embodiment of the present invention, Figure 1B is a further flowchart of step S16 in Fig. 1, Figure 2A is a block diagram of a control device for measuring the service life of a cutting tool according to an embodiment of the present invention, Figure 2B yes Figure 2A A further block diagram of the second decision unit in, image 3 is a block diagram of a system for measuring the service life of a cutting tool according to an embodiment of the present invention.

[0086] like image 3 As shown, in this example, the system 30 for measuring the service life of a cutting tool includes a motor 31 , a cutting tool 32 (hereinafter referred to as tool 32 ), a current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com