Method for predicting fatigue limit of magnesium alloy component

A fatigue limit, magnesium alloy technology, applied in the preparation of test samples, measuring devices, using repetitive force/pulse force to test the strength of materials, etc. Harsh and other problems, to achieve the effect of advanced technology and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

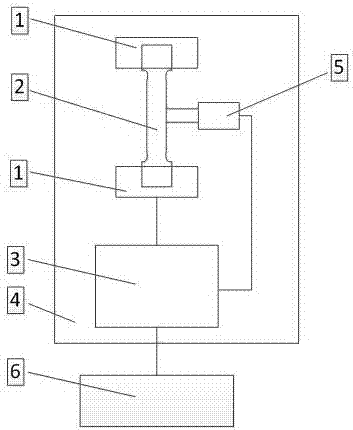

Image

Examples

Embodiment Construction

[0033] A method for predicting the fatigue limit of magnesium alloy components includes the following steps:

[0034] The chemical materials used are: magnesium alloy plate, ethanol, mechanical pencil, scale and sandpaper. The amount to be prepared is as follows: millimeters and milliliters are the unit of measurement

[0035] Magnesium alloy plate: 3 pieces of AZ31B 300 mm×300 mm×5mm

[0036] Ethanol: C2H5OH 500 mL±10 mL

[0037] Sandpaper: SiC 800 mesh 276 mm×0.5 mm×230 mm 2 sheets

[0038] Sandpaper: SiC 1000 mesh 276 mm×0.5 mm×230 mm 2 sheets

[0039] Sandpaper: SiC 1500 mesh 276 mm×0.5 mm×230 mm 2 sheets

[0040] The first test piece processing and preparation

[0041] ① According to the GB / T 228-2008 standard, 15 AZ31B magnesium alloy fatigue specimens were processed, and the specimen axis was the plate rolling direction;

[0042] ② Grind the fatigue test piece with sandpaper to make the surface of the test piece and the wire cutting surface smooth. The roughness of the front and back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com