Micro-open-type safety valve displacement test system and test method

A testing system and safety valve technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as the lack of precise measurement technology for the discharge performance of micro-opening safety valves, and ensure measurement accuracy and measurement accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

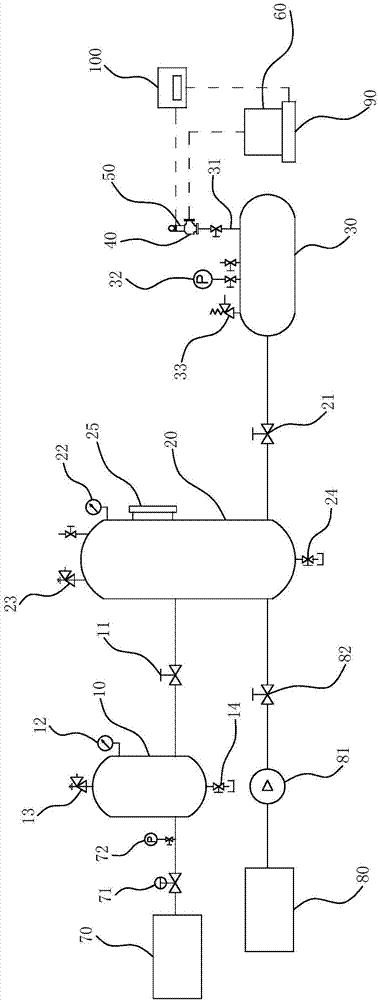

[0031] like figure 1 As shown, the test system includes an air storage tank 10, a water storage tank 20, a test container 30, a sump 60 and a weighing system for measuring the weight of water entering the sump 60, and the test container 30 is connected to There is a branch pipe 31 for installing the valve under test 40, the valve under test 40 is provided with a valve opening height detector, the gas outlet of the gas storage tank 10 communicates with the water storage tank 20, and the water storage tank 20 The water outlet is communicated with the test container 30, the water outlet of the tested valve 40 is connected to the sump 60, the gas in the gas storage tank 10 enters the water storage tank 20 and the water storage tank 20 The water in the test container 30 is continuously pumped into the test container 30 until the water is discharged through the water outlet of the tested valve 40 . The weighing system is an electronic scale 90, and the valve opening height detector...

Embodiment 2

[0040] The test method based on the above-mentioned test system comprises the following steps:

[0041] S1, start the air compressor 70, open the on-off valve three 71, close the on-off valve one 11, the compressed air enters the air storage tank 10 through the pipeline until the pressure in the air storage tank 10 reaches the test requirements, then close the air Compressor 70 and switching valve 3 71;

[0042] S2, close on-off valve two 21, open on-off valve four 82, and turn on water pump 81 until the water level in the water storage tank 20 reaches the test requirements, then close the water pump 81 and on-off valve four 82;

[0043] S3. Simultaneously open the on-off valve one 11 and on-off valve two 21, and the medium water in the water storage tank 20 is pressed into the test container 30 by the compressed air entering the water storage tank 20 until the water passes through the The measured valve 40 overflows; the measured data of the displacement sensor 50 and the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com