Non-contact sample thickness measuring method and device based on Michelson interference principle

A sample thickness, non-contact technology, applied in the field of optical measurement, can solve the problems of high manufacturing cost of instruments, complicated and cumbersome design, etc., to reduce the measurement cost, avoid the illumination distribution, and simplify the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

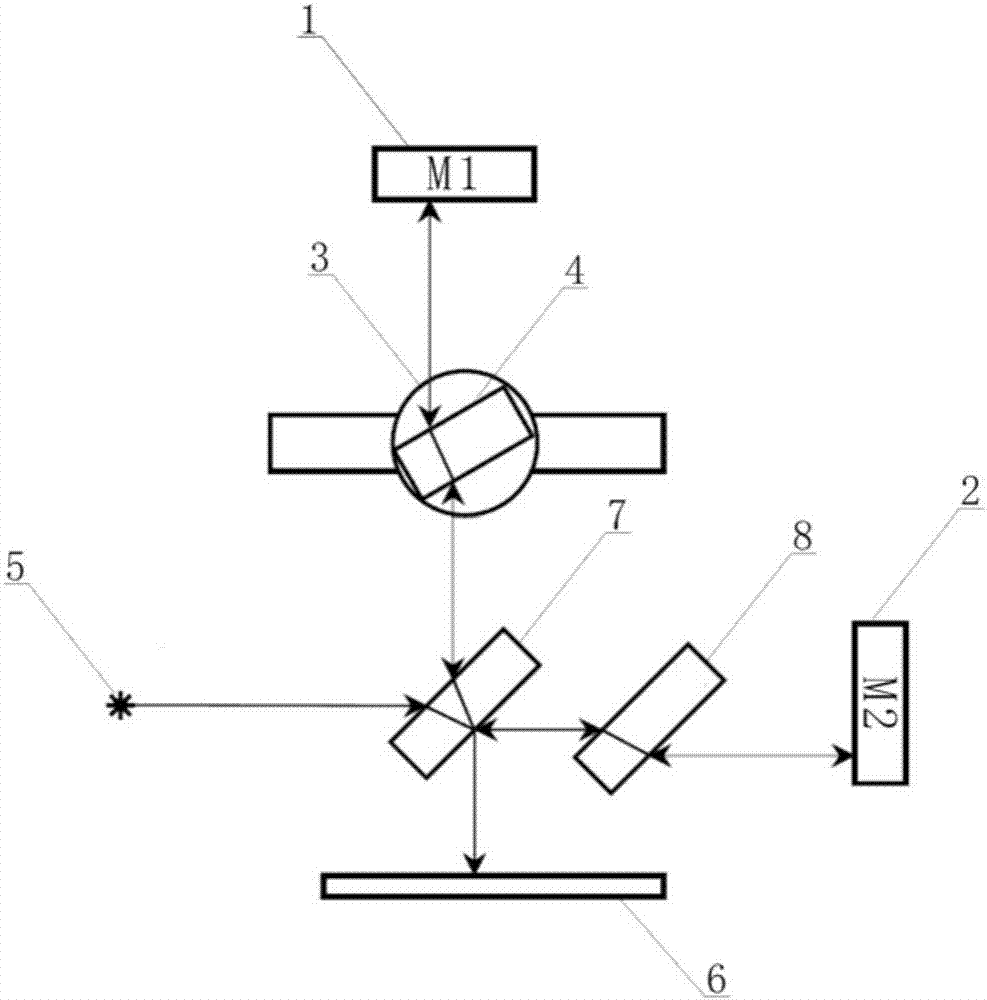

[0034] This embodiment provides a non-contact sample thickness measurement device based on Michelson interference principle, its structure is as follows figure 1 As shown, the measurement device includes a rotatable stage 3 and an optical path assembly mainly composed of an M1 reflector 1, an M2 reflector 2, a laser source 5, a receiving device 6, a beam splitter 7 and a compensation plate 8. The laser source 5, The beam splitter 7, the compensation plate 8 and the M2 reflector 2 are arranged in sequence along the same direction, the beam splitter 7 and the compensation plate 8 are parallel to each other and form an angle of 45° with the mirror surface of the M1 reflector; the rotatable stage 3 is located on the M1 reflector 1 and the splitter plate 7; the receiving device 6 is a receiving screen.

[0035] When the above-mentioned non-contact sample thickness measurement device based on the Michelson interference principle is used, the beam splitter 7 divides the laser light e...

Embodiment 2

[0066] This embodiment provides a non-contact sample thickness measurement device based on Michelson interference principle, its structure is as follows image 3 As shown, the measuring device includes a fixed stage 3' for placing the sample 4 to be tested and an optical path assembly packaged in a casing 13; the optical path assembly is mainly composed of an M1 mirror 1, M2 mirror 2, laser source 5, receiving device 6, beam splitter 7, compensation board 8, micro-electromechanical gyroscope 10 and single-chip microcomputer 11; laser source 5, beam splitter 7, compensation board 8 and M2 mirror 2 are in the same direction Arranged in sequence, the beam splitter 7 and the compensation plate 8 are parallel to each other and form an angle of 45° with the mirror surface of the M1 mirror; the base is installed in the housing 13 through the central axis 9, and the micro-electromechanical gyroscope 10 is installed on the central axis 9 , to realize the linkage between base rotation a...

Embodiment 3

[0079] This embodiment provides a non-contact sample thickness measurement device based on Michelson interference principle, its structure is as follows Figure 4 As shown, the measuring device is basically the same as the device provided in Embodiment 2, the main difference is that the single-chip microcomputer 11 in this embodiment is arranged outside the casing 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com