Deep microwave drying method for metal storage tank

A drying method and storage tank technology, which are applied in the directions of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of large quantity demand, scrapped storage tanks, complicated structure, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

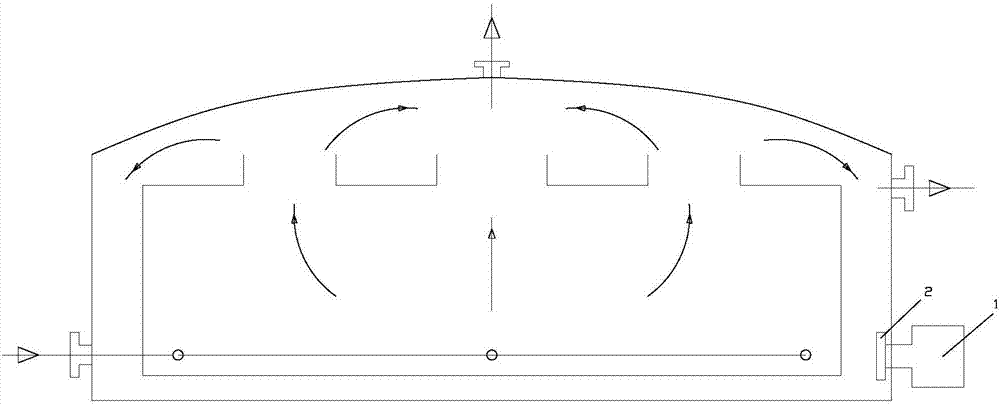

Image

Examples

Embodiment 1

[0024] Embodiment 1 (traditional purging)

[0025] A low-temperature propylene storage tank with a total volume of 21,200m3 must be dried after the hydrostatic test before being put into operation, and the dew point must be ≤ -40°C. The method of purging with dry nitrogen is used for continuous purging and drying. The actual operation takes nearly 52 hours to meet the technical requirements, and the use of nitrogen is 70000Nm3 (about 87.5 tons).

experiment example 2

[0026] Experimental example 2 (method of the present invention)

[0027] A small steel container with a diameter of 1.2 meters and a height of 1.5 meters is used for the test.

[0028] The first step is to fully spray water on the inner wall of the container, and then blow it with absolutely dry compressed air. The Celsius water analyzer, blowing air flow rate is 1.5 cubic meters per minute, and the dew point is reduced from 15 degrees to -30 degrees for 167 minutes.

[0029] In the second step, after fully spraying water on the inner wall of the container, blow it with absolutely dry compressed air. For the water analyzer in Celsius, a microwave feeding port is opened on the side of the container near the bottom. The microwave uses 2450MHz microwave power of 1000 watts, and a microwave uniform distributor is installed. The blowing flow rate is also 1.5 cubic meters per minute, and the dew point has dropped from 15 degrees to -30 degrees, and it has been used for 73 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com