Balanced direct-acting type surge relief valve

A direct-acting, balanced technology, applied in valve details, valve devices, engine components, etc., can solve the problems of inability to open immediately, poor adjustable performance, water hammer damage, etc., to ensure safe and effective operation, running resistance Small, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

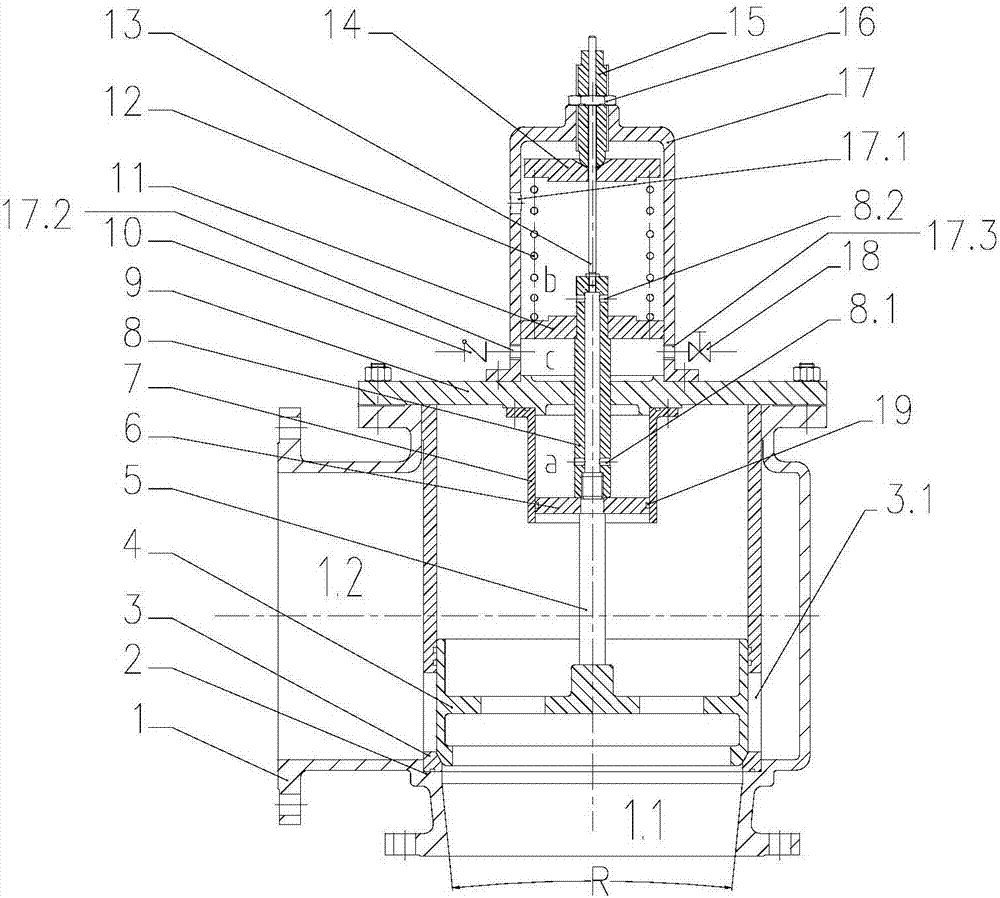

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

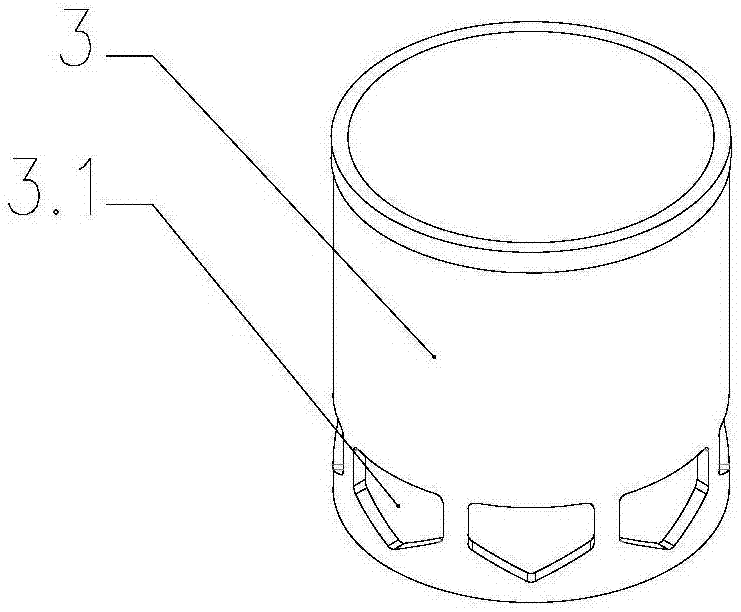

[0024] see figure 1 with figure 2 , Balanced direct-acting water hammer relief valve, the valve body 1 adopts an angle type, or is designed as a straight-through type, and a valve seat 2 is provided between the inlet port 1.1 and the outlet port 1.2 of the valve body 1, and the valve body 1 passes through the valve body 1. The blue hole is equipped with a sleeve 3 on the valve seat 2, and the sleeve 3 is positioned through the valve cover 9 installed on the flange of the valve body. 2. The V-shaped flow hole 3.1 opened on the side wall at one end is connected. The sleeve 3 is provided with an adjusting cylinder 4 corresponding to the inlet end 1.1 of the valve body 1. The adjusting cylinder 4 is a cylindrical member connected up and down. When the adjustment cylinder 4 moves up and down, it can connect or cut off the V-shaped flow hole 3.1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com