Adhesive for producing rubber shoes and preparation method of adhesive

A technology for adhesives and rubber shoes, applied in the direction of natural rubber adhesives, adhesives, adhesive types, etc., can solve the problem of adhesive impact resistance, low peeling temperature and bonding strength, shoe uppers and shoes. Insufficient bonding and reduced service life of rubber shoes, etc., to achieve the effect of not easy to agglomerate and harden, good adhesion, and strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The adhesive used for producing rubber shoes includes the following raw materials in parts by weight: 100 parts of national standard No. 1 natural rubber, 2.8 parts of sulfur, 2 parts of accelerator M, 1 part of accelerator DM, 1 part of accelerator D, zinc carbonate 7 parts, 1 part of stearic acid, 2 parts of phenolic resin, 2 parts of rosin, 3 parts of terpene resin, 6.5 parts of polyisocyanate, 400 parts of No. 120 solvent naphtha.

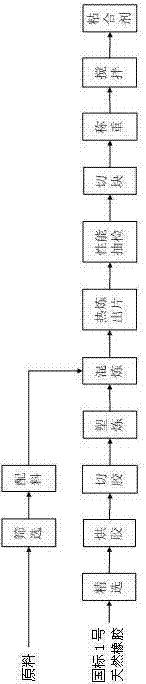

[0060] The above-mentioned preparation method for producing the adhesive of rubber shoes, comprises the following steps:

[0061] (1) Add accelerator M, accelerator DM, accelerator D, zinc carbonate, stearic acid, and rosin after the national standard No. 1 natural rubber is masticated to obtain the adhesive master sheet.

[0062] (2) Cut the mixed adhesive master piece into pieces, weigh it, put it into the mixer, then add No. 120 solvent oil, stir for 2 hours, add phenolic resin and terpene resin, stir for 20 hours, add sulfur Continu...

Embodiment 2

[0065] The adhesive used to produce rubber shoes includes the following raw materials in parts by weight: 100 parts of national standard No. 1 natural rubber, 2.5 parts of sulfur, 2.5 parts of accelerator M, 0.5 parts of accelerator DM, 1.5 parts of accelerator D, zinc oxide 5 parts, 1.5 parts of stearic acid, 2.5 parts of phenolic resin, 1.5 parts of rosin, 2.5 parts of terpene resin, 10 parts of polyisocyanate, 350 parts of No. 120 solvent oil.

[0066] The above-mentioned preparation method for producing the adhesive of rubber shoes, comprises the following steps:

[0067] (1) Add accelerator M, accelerator DM, accelerator D, zinc oxide, stearic acid, and rosin after the national standard No. 1 natural rubber is masticated to obtain an adhesive master sheet.

[0068] (2) Cut the mixed adhesive master piece into pieces, weigh it, put it into the mixer, then add No. 120 solvent oil, stir for 2 hours, add phenolic resin and terpene resin, stir for 20 hours, add sulfur Continu...

Embodiment 3

[0071]The adhesive used to produce rubber shoes, by weight, includes the following raw materials: 100 parts of national standard No. 1 natural rubber, 3 parts of sulfur, 1.5 parts of accelerator M, 1.5 parts of accelerator DM, 0.5 part of accelerator D, zinc carbonate 9 parts, 0.5 parts of stearic acid, 1.5 parts of phenolic resin, 2.5 parts of rosin, 3.5 parts of terpene resin, 3 parts of polyisocyanate, 450 parts of No. 120 solvent naphtha.

[0072] The preparation method of the above-mentioned adhesive used for producing rubber shoes is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com