Method for preparing phenol and acetone through reaction rectification decomposition of CHP

A technology of phenol acetone and reactive distillation, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low product selectivity, high investment, and large floor area, and achieve high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

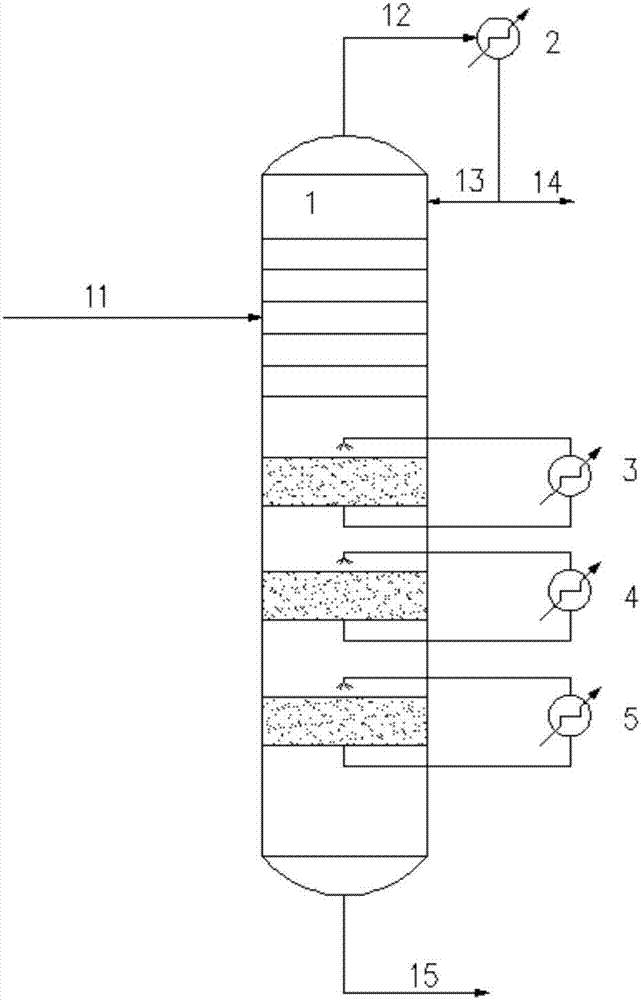

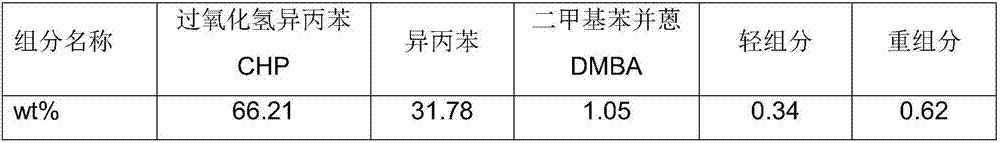

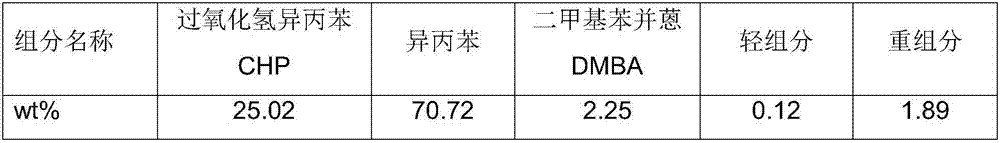

[0022] A kind of method that reactive distillation decomposes CHP prepares phenol acetone, as figure 1 As shown, taking the 3-section solid catalyst bed as an example, the cumene hydroperoxide CHP raw material (11) enters the reactive distillation column (1) from the middle, and enters the reaction section with the gravity flow to contact the solid catalyst, and CHP decomposition occurs The reaction produces phenol acetone and produces a large amount of heat of reaction. All the liquid phase acetone and a small amount of raw material CHP and a small amount of cumene are evaporated into the gas phase and discharged from the upper part of the reaction section; the liquid phase material without acetone is reacted from the reactive distillation column (1) The lower part of the section is drawn, and in the intercooler (3), the intercooler (4), and the intercooler (5), it exchanges heat with the circulating cooling water and removes the heat of decomposition reaction, and the reactiv...

Embodiment 2

[0029] According to the conditions and steps described in Example 1, only the production scale of the phenol-acetone plant is changed to 200,000 tons / year, and the method for preparing phenol-acetone by reactive distillation and decomposition of CHP of the present invention is adopted, and the process parameters are: reactive distillation column reaction section The operating temperature is 82°C, and the operating pressure is 132kPaA; the aspect ratio of the reactor is 6:1, and the reactor is filled with 4 stages of catalysts. The operating temperature of the rectification section of the reactive distillation tower is 53°C, the operating pressure is 98kPaA, and the reflux ratio is 0.71; the number of rectification trays is 46, and the position of the feed plate is the 44th tray from top to bottom.

[0030] Thus, the selectivity of phenol is 99.50%, the selectivity of acetone is 99.35%, and the purity of acetone product is 99.91wt%. Compared with [Comparative Example 1], the nu...

Embodiment 3

[0032] According to the conditions and steps described in Example 1, only the production scale of the phenol-acetone plant is changed to 350,000 tons / year, and the method for preparing phenol-acetone by reactive distillation and decomposition of CHP of the present invention is adopted, and the process parameters are: reactive distillation column reaction section The operating temperature is 82°C, and the operating pressure is 132kPaA; the aspect ratio of the reactor is 6:1, and the reactor is filled with 4 stages of catalysts. The operating temperature of the rectification section of the reactive distillation tower is 53°C, the operating pressure is 98kPaA, and the reflux ratio is 0.71; the number of rectification trays is 46, and the position of the feed plate is the 44th tray from top to bottom.

[0033] Thus, the selectivity of phenol is 99.45%, the selectivity of acetone is 99.30%, and the purity of acetone product is 99.91wt%. Compared with [Comparative Example 1], the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com