Special slurry pressing material for high-speed railway roadbed rush repair reinforcement and grouting method thereof

A technology for high-speed railways and roadbeds, which is applied to roads, infrastructure engineering, soil protection, etc., can solve problems such as the inability to use high-speed railways for roadbed repair, insufficient strength of grouting materials, etc., to achieve rich sources of raw materials and no bleeding of the slurry. , The effect of preventing grouting from blocking the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

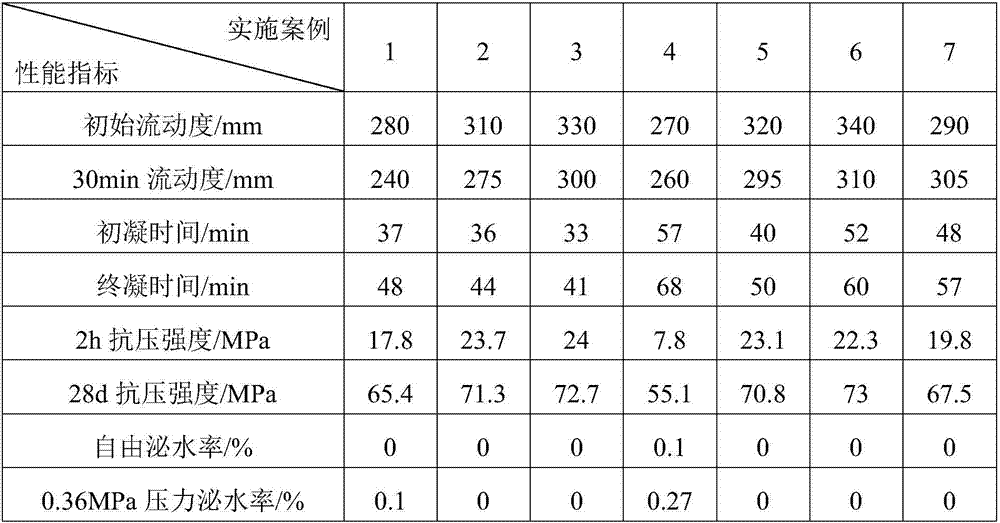

Examples

Embodiment 1

[0042] Example 1: Preparation of a special grouting material for emergency repair and reinforcement of high-speed railway subgrades, weighed according to the mass ratio: 60 kg of rapid-hardening sulphoaluminate cement, 3 kg of silicon micropowder, 6.22 kg of anhydrous anhydrite, plastic expansion Agent 0.03kg, sand 30kg, water reducer 0.3kg, hardening accelerator 0.05kg, retarder 0.2kg, stabilizer 0.03kg, defoamer 0.04kg, latex powder 0.13kg.

[0043] The silicon micropowder used in this embodiment is semi-encrypted or high-encrypted active silicon micropowder, with an active SiO2 content of ≥90%; the plastic expansion agent used is one of azodicarbonamide, azobisisobutyronitrile or azobisisoheptanonitrile A mixture of one or more of them, the average particle size of the azo compound is ≤10μm, and the gas generation rate is ≥200ml / g; the sand used is well-graded washed and dried yellow sand, river sand or natural quartz sand. Particle size ≥ 70 mesh; the water reducer used is...

Embodiment 2

[0046] Example 2: Prepare a special grouting material for emergency repair and reinforcement of high-speed railway embankment, weigh according to the mass ratio: 80kg of rapid-hardening sulphoaluminate cement, 1.4kg of silica micropowder, 5.9kg of anhydrous anhydrite, plastic Expansion agent 0.02kg, sand 12kg, water reducer 0.25kg, hardening accelerator 0.04kg, retarder 0.15kg, stabilizer 0.03kg, defoamer 0.05kg, latex powder 0.16kg.

[0047] The silicon micropowder used in this embodiment is semi-encrypted or high-encrypted active silicon micropowder, with an active SiO2 content of ≥90%; the plastic expansion agent used is one of azodicarbonamide, azobisisobutyronitrile or azobisisoheptanonitrile A mixture of one or more of them, the average particle size of the azo compound is ≤10μm, and the gas generation rate is ≥200ml / g; the sand used is well-graded washed and dried yellow sand, river sand or natural quartz sand. Particle size ≥ 70 mesh; the water reducer used is one or a...

Embodiment 3

[0050] Example 3: Preparation of a special grouting material for emergency repair and reinforcement of high-speed railway subgrades, weighed according to the mass ratio: 90 kg of rapid-hardening sulphoaluminate cement, 4 kg of silicon micropowder, 5.03 kg of anhydrous anhydrite, plastic expansion 0.03kg water reducing agent, 0.05kg hardening accelerator, 0.15kg retarder, 0.03kg stabilizer, 0.06kg defoamer, 0.35kg latex powder, sand is not added in this embodiment.

[0051] The silicon micropowder used in this embodiment is semi-encrypted or high-encrypted active silicon micropowder, with an active SiO2 content of ≥90%; the plastic expansion agent used is one of azodicarbonamide, azobisisobutyronitrile or azobisisoheptanonitrile A mixture of one or more of them, the average particle size of the azo compound is ≤10μm, and the gas generation rate is ≥200ml / g; the sand used is well-graded washed and dried yellow sand, river sand or natural quartz sand. Particle size ≥ 70 mesh; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Gas output | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com