Method for preparation of pharmaceutical adjuvant silica by bipolar membrane electrodialysis

A bipolar membrane electrodialysis and silica technology, applied in the field of ion exchange membranes, can solve the problems of long production process, long preparation time, expensive raw materials of sol-gel method, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1.1 Soak the titanium sheet in concentrated hydrochloric acid until it softens, take it out, wash it several times with distilled water, and then dry it to obtain a dried titanium sheet.

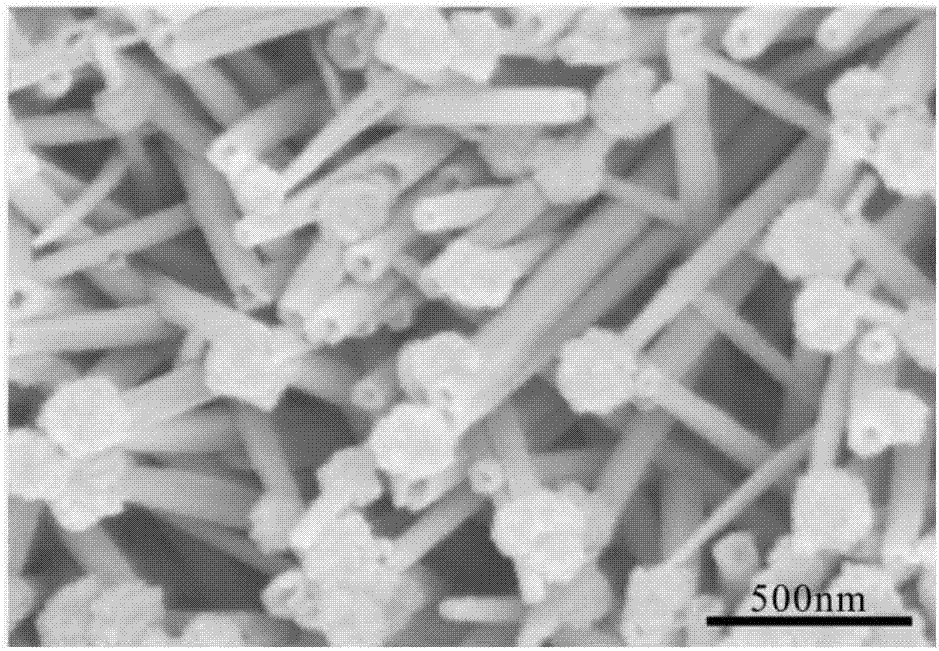

[0058] 1.2 Put the dried titanium sheet into a polytetrafluoroethylene reactor containing 50ml of an aqueous solution containing 4.0mmol cobalt nitrate, 8mmol ammonium fluoride and 20mmol urea, and react at 80°C for 12h to make the titanium sheet Oriented basic cobalt carbonate nanowires grow on the surface.

[0059] 1.3 Put the oriented-type basic cobalt carbonate nanowire titanium sheet grown on the surface obtained in step 1.2 into a polytetrafluoroethylene reactor filled with 20ml of an aqueous solution containing 4.2g 2-methylimidazole and 3.3g triethylamine In the process, at 100° C. for 100 minutes, the alignment-type cobalt basic carbonate nanowires on the surface of the titanium sheet were converted into alignment-type ZIF-67 nanotubes.

[0060] 1.4 Soak the titanium sheet w...

Embodiment 2

[0073] 2.1 Soak the titanium sheet in concentrated hydrochloric acid until it softens, take it out, wash it several times with distilled water, and then dry it to obtain a dried titanium sheet.

[0074] 2.2 Put the dried titanium sheet into a polytetrafluoroethylene reactor containing 50 ml of an aqueous solution containing 5.0 mmol of cobalt nitrate, 9.4 mmol of ammonium fluoride and 29.4 mmol of urea, and react for 13 hours at a temperature of 75 ° C, so that Oriented basic cobalt carbonate nanowires grow on the surface of the titanium sheet.

[0075] 2.3 Put the oriented-type basic cobalt carbonate nanowire titanium sheet grown on the surface obtained in step 2.2 into a polytetrafluoroethylene reactor filled with 20ml of an aqueous solution containing 5.6g of 2-methylimidazole and 4.8g of triethylamine , at a temperature of 90° C., reacted for 150 minutes, and the orientation-type basic cobalt carbonate nanowires on the surface of the titanium sheet were converted into orie...

Embodiment 3

[0084] 3.1 Soak the titanium sheet in concentrated hydrochloric acid until it softens, take it out, wash it several times with distilled water, and then dry it to obtain a dried titanium sheet.

[0085] 3.2 Put the dried titanium sheet into a polytetrafluoroethylene reactor containing 50 ml of an aqueous solution containing 6.0 mmol of cobalt nitrate, 10.0 mmol of ammonium fluoride and 26.5 mmol of urea, and react for 11 hours at a temperature of 90 ° C, so that Oriented basic cobalt carbonate nanowires grow on the surface of the titanium sheet.

[0086] 3.3 Put the oriented-type basic cobalt carbonate nanowire titanium sheet grown on the surface obtained in step 3.2 into a polytetrafluoroethylene reactor filled with 20ml of an aqueous solution containing 4.5g 2-methylimidazole and 3.7g triethylamine , at a temperature of 80°C, reacted for 200 minutes, and the orientation type basic cobalt carbonate nanowires on the surface of the titanium sheet were converted into orientation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com