Automatic label flattening mechanism

An automatic and labeling technology, applied in labels, labeling machines, packaging, etc., can solve problems such as affecting the health of operators, low work efficiency, residual small bubbles, etc., to achieve high operation accuracy, reduce manual operations, and precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

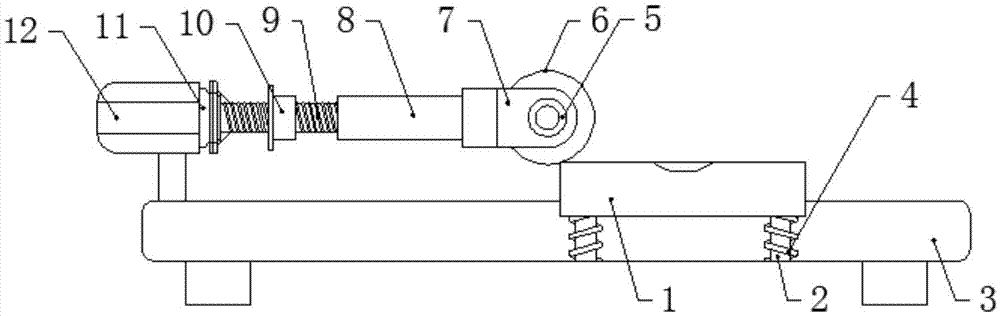

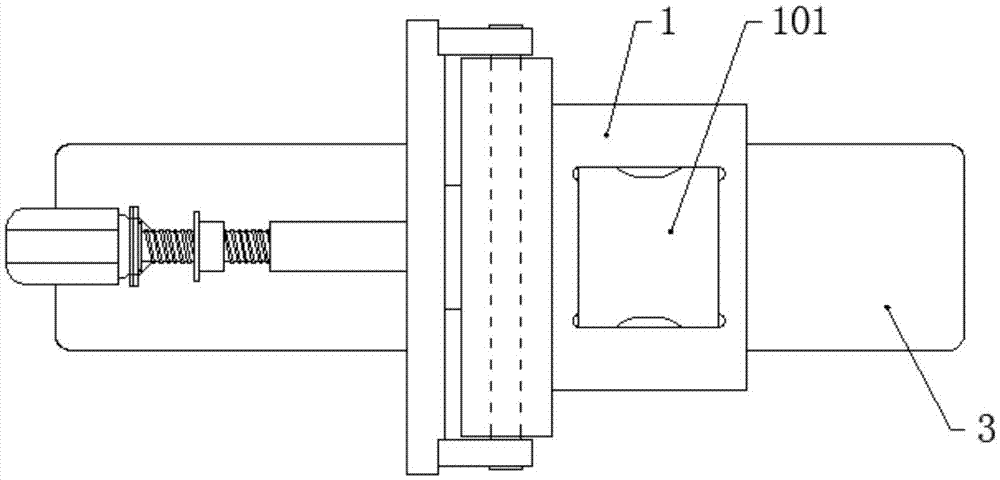

[0019] Such as Figure 1-Figure 3 As shown, the present invention provides an automatic label flattening mechanism, including a fixed plate 1 and an automatic flattening device.

[0020] On the fixed plate 1, about the central region has a fixed groove 101 for fixing the product, and the periphery of the fixed groove 101 is provided with an arc live opening for conveniently taking out the product.

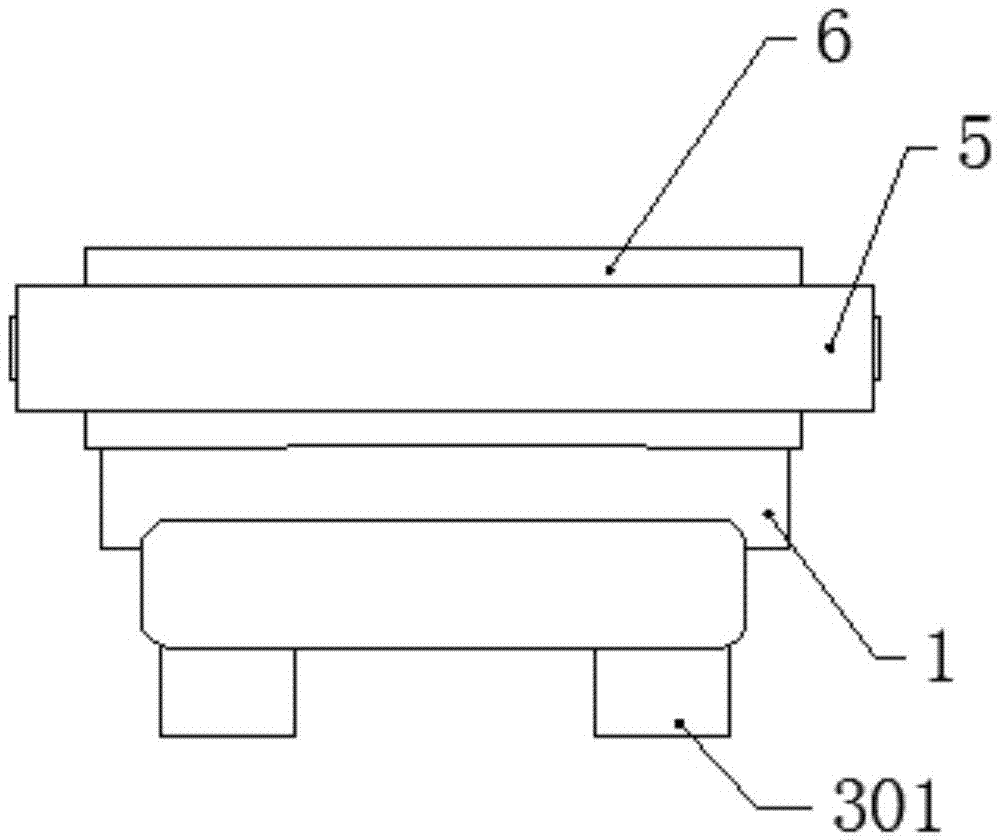

[0021] The automatic flattening device comprises a base 3, a pressing roller 6, a connecting rod 8 and a propulsion device.

[0022] The propulsion device and the base 3 are fixedly connected by bolts, and the base 3 is provided with a height-adjustable leg 301, which can be adjusted according to the corresponding working environment to keep the whole device stable.

[0023] One end of the connecting rod 8 is connected with the propulsion device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com