Gate removing structure of injection mold and injection mold

A technology of injection mold and dehydration port, applied in the field of dehydration port structure and injection mold, can solve the problems of unstable structure, easy deformation or burning, increase mold cost, etc., achieve simple and stable structure, improve appearance quality, and save mold cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

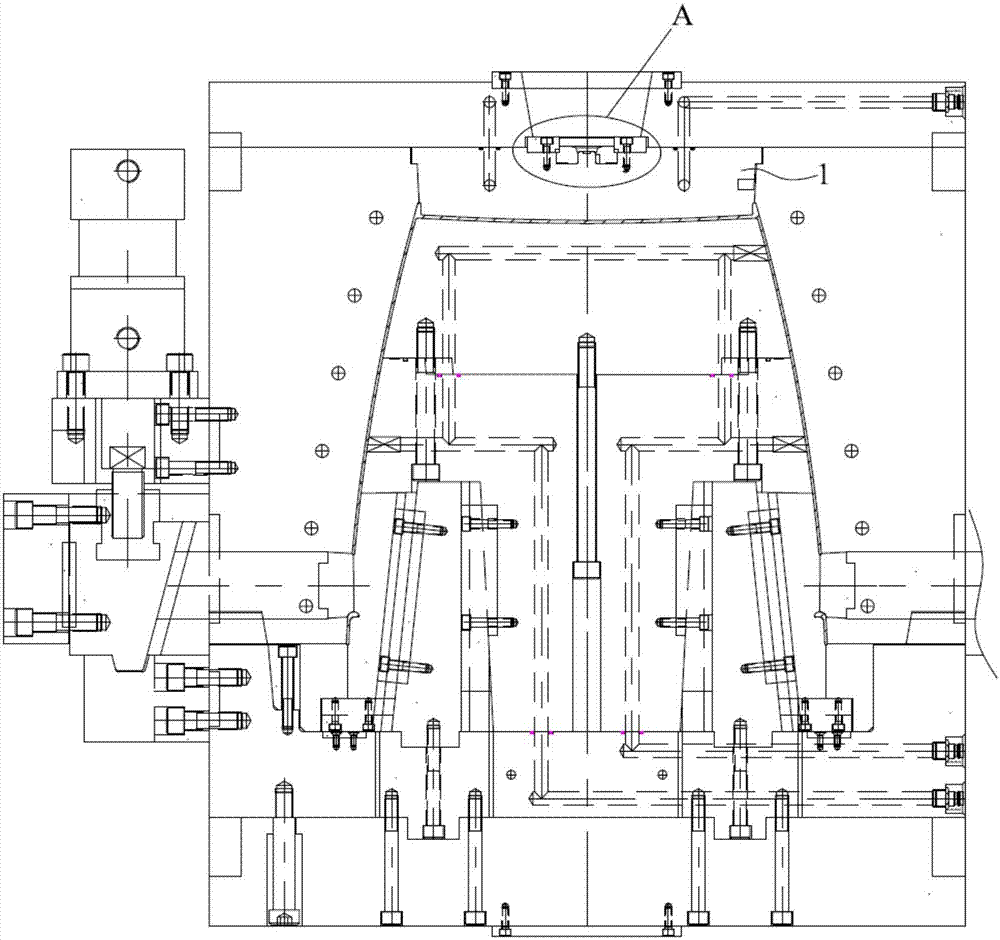

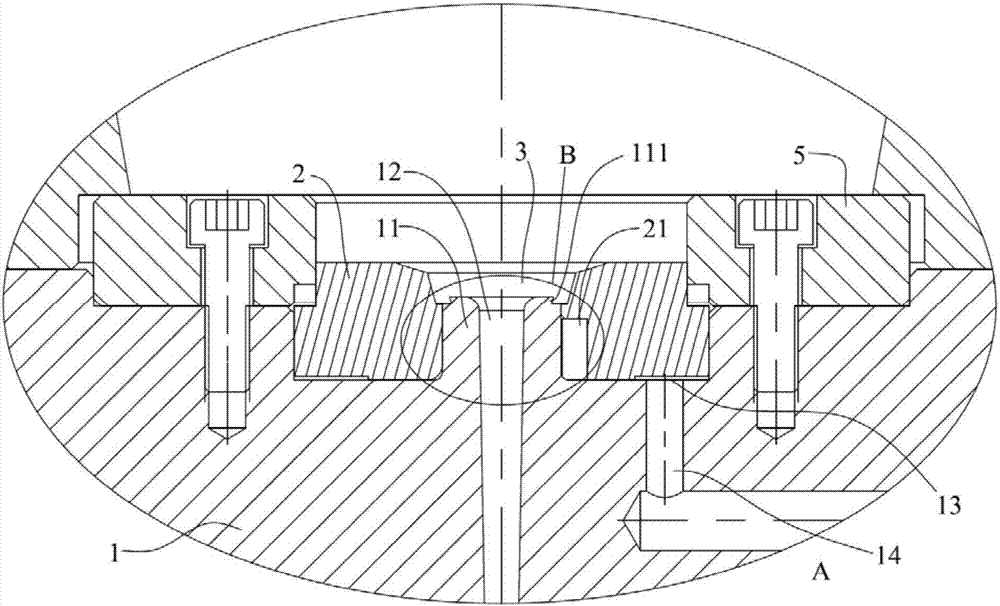

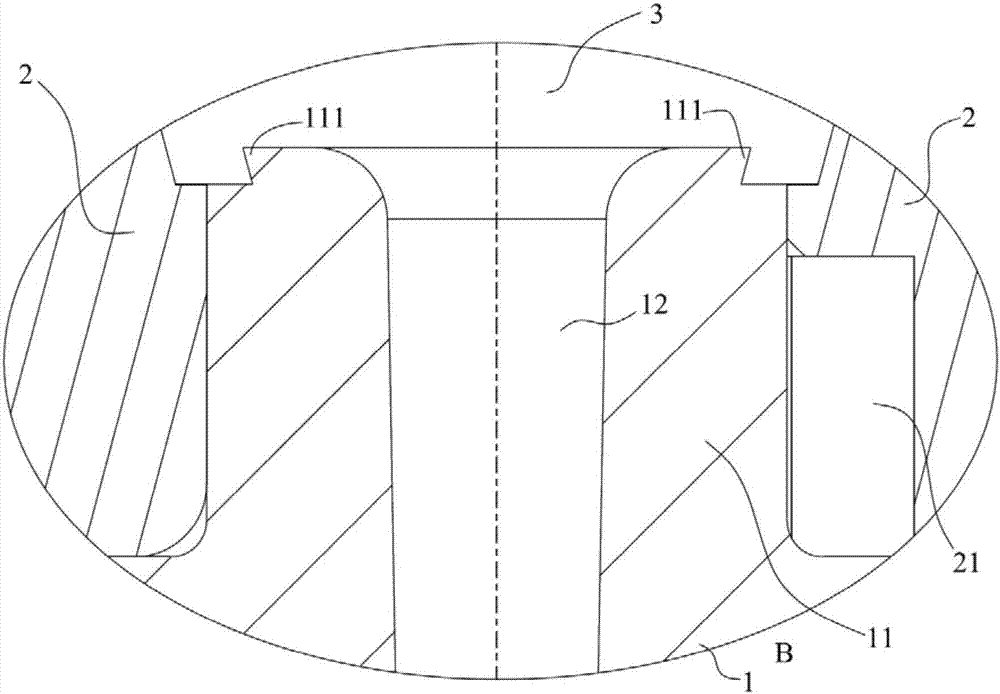

[0025] This embodiment provides a dewatering port structure of an injection mold, such as Figure 1-Figure 4 As shown, it includes a front mold insert 1, a floating insert 2 and a driving structure. The end of the front mold insert 1 near the nozzle is protruded with a boss 11, and the floating insert 2 is sleeved outside the boss 11 and can move along the boss. 11 slides, the boss 11 is provided with an undercut portion 111 whose width becomes larger along the convex direction of the boss 11, and the boss 11 is provided with a flow channel 12 downward from the top surface, and the inner cavity of the floating insert 2 and the boss 11 The top end of the nozzle forms a nozzle area 3 communicating with the flow channel 12, the undercut portion 111 is located in the nozzle area 3, and the driving structure drives the floating insert 2 to slide along the boss 11. This embodiment also provides a kind of injection mold with this dewatering port structure, and its working process is ...

Embodiment 2

[0037] Different from Embodiment 1, in this embodiment, the drive structure includes an ejector that can move along the direction of the boss 11 and a drive that drives the ejector to move. The ejector is located at the bottom of the floating insert 2, and the floating insert There is a through hole in the middle part of the piece 2, and the through hole is sleeved on the boss 11. The through hole is sealed with the side of the boss 11, and the bottom of the through hole is provided with a gap 21 upward. When the floating insert 2 moves upward to the gap 21 When exposed, the gas enters the nozzle area 3 from the gap 21 . In this embodiment, the driving structure of the floating insert 2 is replaced by the ejector and the driving piece, and the floating insert 2 can be directly driven by the mechanical structure to separate the cold material 4. However, in order to better remove the cold material 4 , it is still necessary to eject the cold material 4 with the help of gas, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com