Auxiliary tooling and application method for positioning welding of front and rear half-hanging tank seats

A technology of auxiliary tooling and positioning welding, which is applied in the direction of welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of high damage rate of simple tooling, manpower consumption, loss of manpower, materials and other resources, and achieve the improvement of semi-trailer Enhance product quality, degree of freedom and flexibility, and shorten the time spent on positioning and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

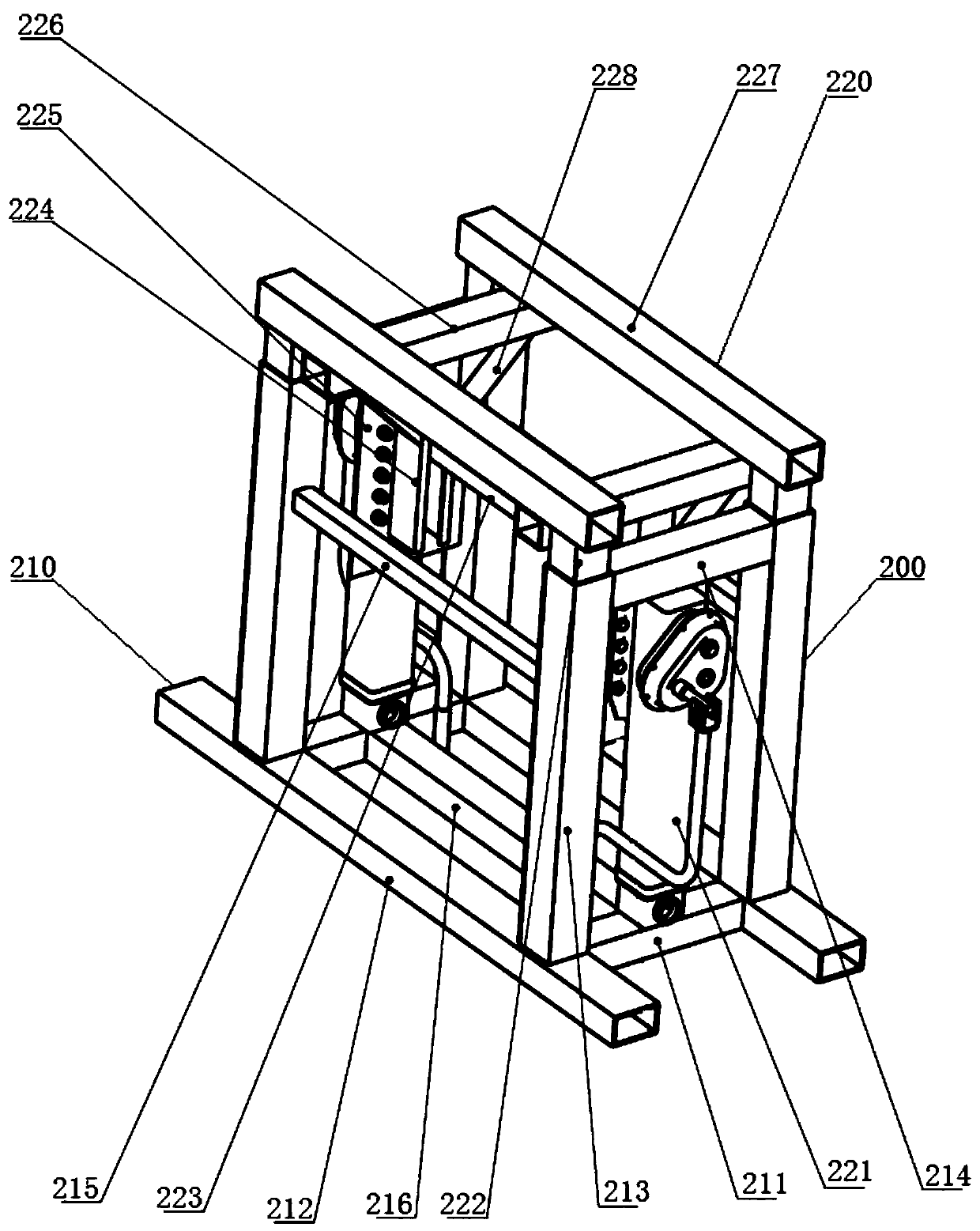

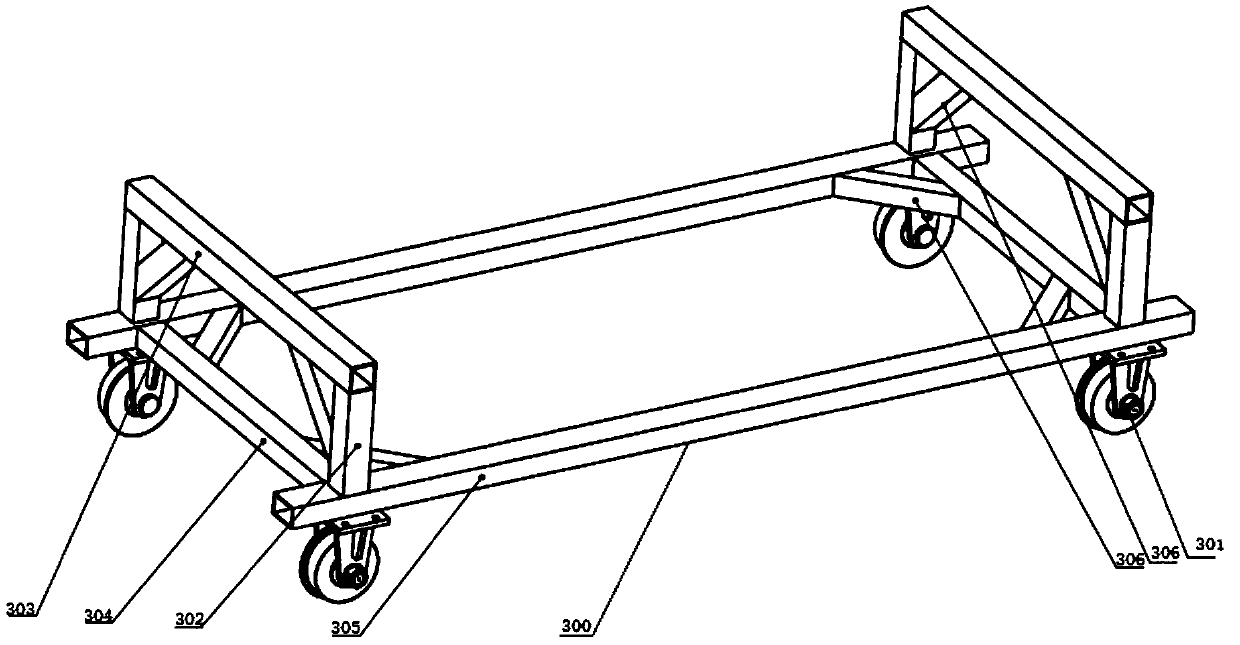

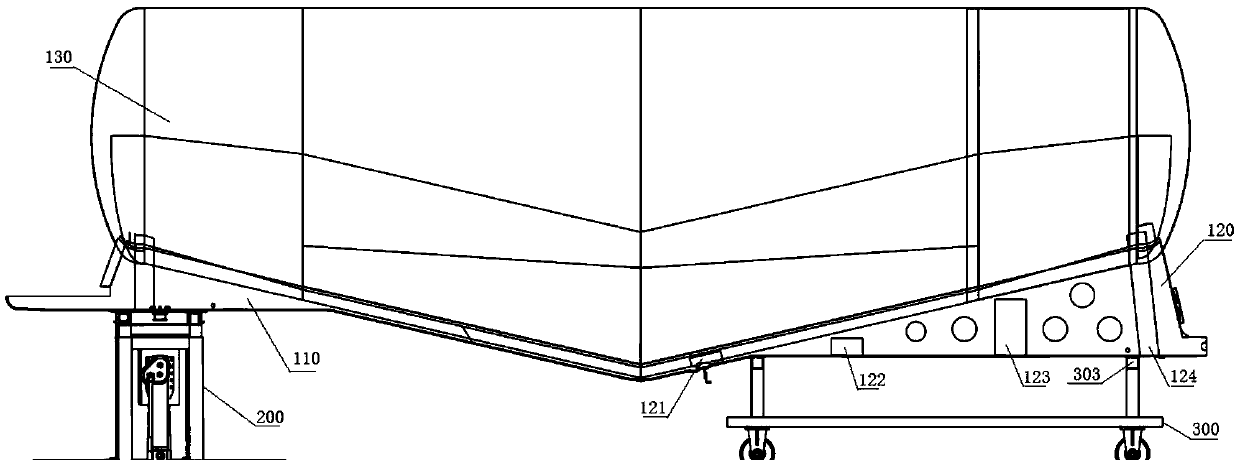

[0031] Depend on figure 1 , figure 2 , image 3 It can be seen that an auxiliary tooling for the positioning welding of the front and rear semi-hanging tank seats, including a lifting saddle 200 and a four-wheel saddle 300, is characterized in that the lifting saddle 200 is used for adjusting the height of the front tank seat 110 during calibration; The saddle 300 is used to support the rear tank seat 120 during calibration, simulating the actual height.

[0032] Lifting saddle 200 comprises support base 210 and lifting mechanism 220, and lifting mechanism 220 is installed on the support base 210; Support base 210 comprises base beam 211, base longitudinal beam 212 and support column 213, and described base beam 211 and base Longitudinal beam 212 connects and forms square frame shape, and support column 213 is established on base longitudinal beam 212; Support column 213 is a hollow structure; The movable base 226; the outrigger 221 is lifted by mechanical or hydraulic lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com