Wire cutting mechanism

A wire cutting machine tool and transmission mechanism technology, applied in metal processing equipment, manufacturing tools, electric processing equipment, etc., can solve the problems of increasing maintenance costs, accelerating wear, and reducing motor life, so as to reduce maintenance costs and prolong service life. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

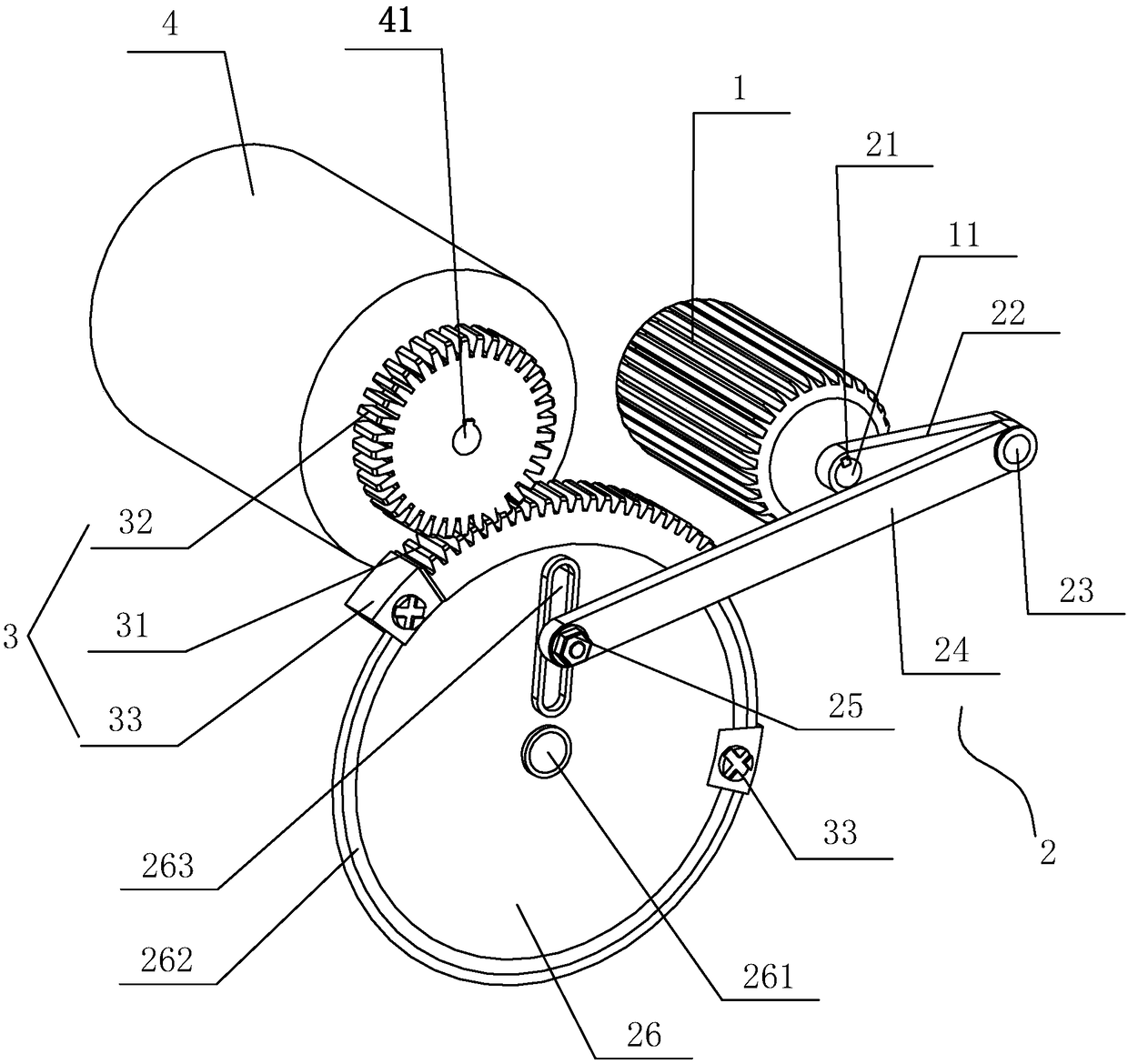

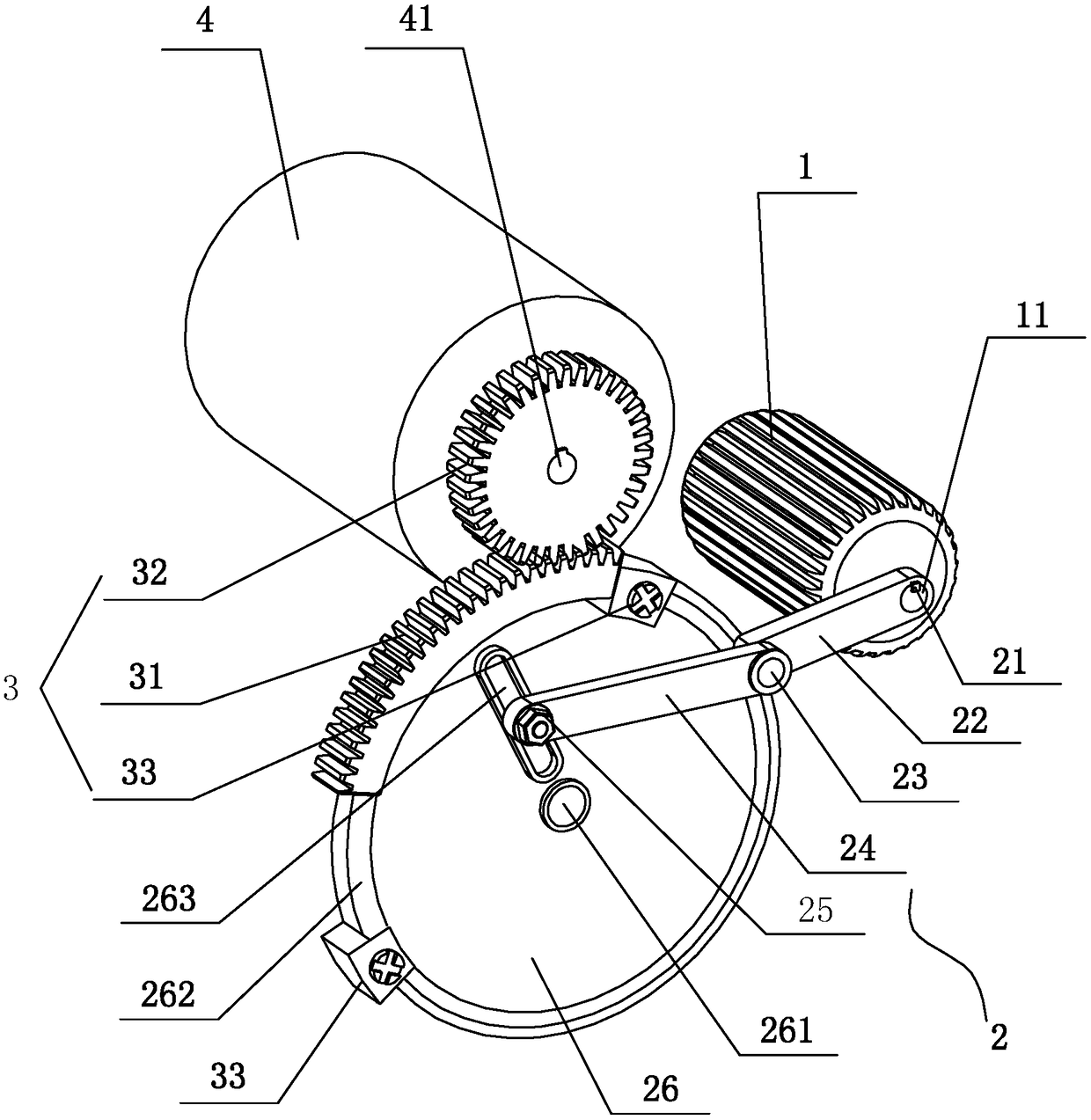

[0037] A wire-feeding mechanism for a wire-cut machine tool, comprising a motor 1, a wire storage tube 4, a crank-rocker mechanism 2, and a rack-and-pinion transmission mechanism 3, the output shaft 11 of the motor is connected to the crank end of the crank-rocker mechanism 2, The rocker end of the crank rocker mechanism 2 is connected with the transmission shaft 41 of the wire storage drum through the rack and pinion transmission mechanism 3 .

[0038] Described crank rocker mechanism 2 comprises crank 22, connecting rod 24, balance wheel 26, and one end of crank 22 is fixed on the output shaft 11 of electric motor by crank fixed key 21, to realize the function of crank; The hinge 23 is connected with one end of the connecting rod 24 to realize the function of the revolving pair; the other end of the connecting rod 24 is connected with the balance wheel 26 through a fastener 25—a fastening nut, and the balance wheel 26 is installed on the balance wheel shaft 261 to realize Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com