Preparation method of medical biodegradable zinc alloy capillary wire material

A technology of zinc alloy and capillary wire, which is applied in the field of preparation of medical biodegradable zinc alloy capillary wire, can solve problems such as poor mechanical properties, surface cracks, and affecting treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a medical biodegradable zinc alloy capillary wire, comprising the following steps:

[0030] (1) Vacuum melting and homogenizing heat treatment of medical biodegradable zinc alloy in sequence to obtain zinc alloy ingot;

[0031] (2) removing surface defects and extruding the zinc alloy ingots obtained in the step (1) successively to obtain thick zinc alloy rods;

[0032] (3) swaging and annealing the thick zinc alloy rods obtained in the step (2) successively to obtain thin rods;

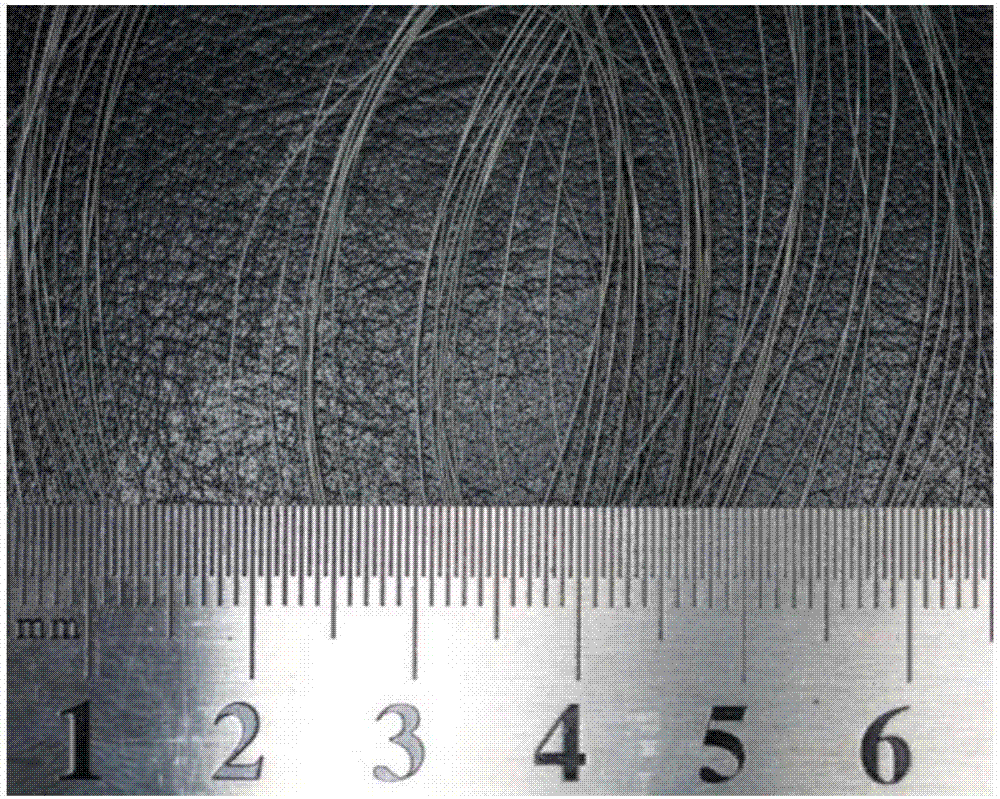

[0033] (4) After coating the surface of the fine rod obtained in the step (3) with a graphite lubricant coating and drawing it by cold drawing, a medical biodegradable zinc alloy capillary wire is obtained, and the diameter of the capillary wire is less than 0.1 mm.

[0034] The present invention does not have any special limitation on the source of the medical biodegradable zinc alloy, and the sources of the medical biodegradable zinc alloy or co...

Embodiment 1

[0070] Get the as-cast zinc alloy ingot (50mm×200mm outer diameter), peel off the outer skin with a lathe, and become an ingot with an outer diameter of 45mm. After homogenization heat treatment, the heat treatment temperature is 350°C, the holding time is 6h, and then cooled to room temperature with the furnace;

[0071] The extrusion die in the extruder is preheated to 120° C., the extrusion pressure is adjusted to 10 MPa, and the extrusion speed is controlled to 3 mm / s. The above-mentioned zinc alloy ingot was heated to 200° C. in an electric heating box for 3 hours. Put it into the mold, start the extruder, and extrude into a thick bar with a diameter of 12mm;

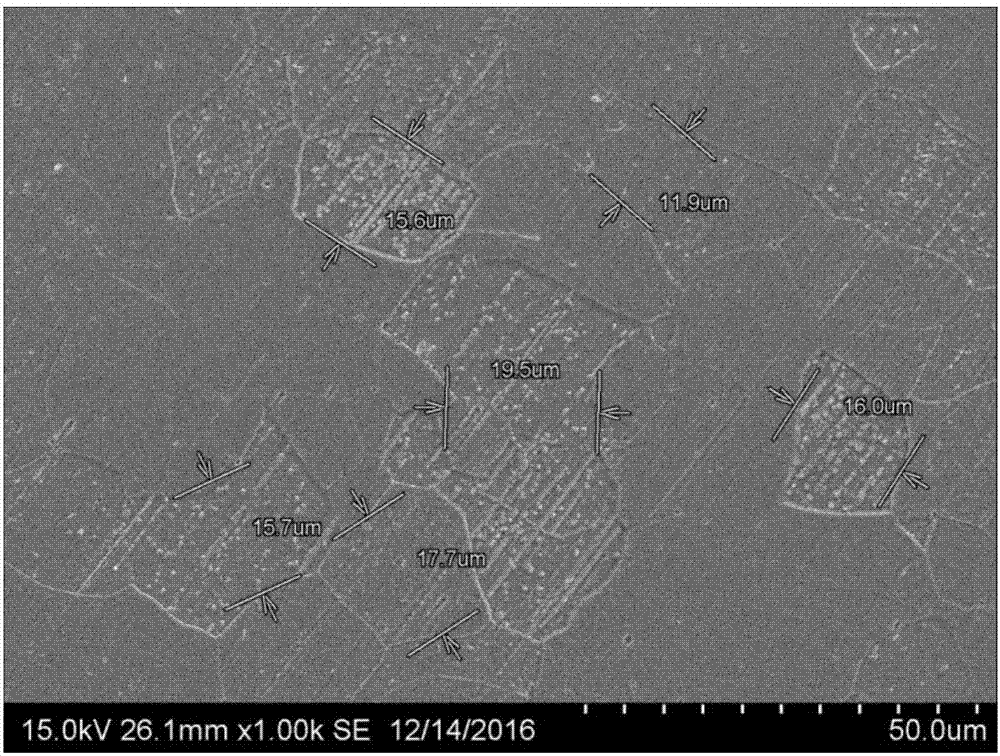

[0072] Pre-heat the swaging die in the swaging machine to 150°C, put the above-mentioned hot extruded thick bar and heat it to 280°C by electromagnetic induction to perform two passes of heating swaging. The frequency of electromagnetic induction heating is 500Hz, and the feeding speed of the material is 7mm / s. ...

Embodiment 2

[0081] Get the as-cast zinc alloy ingot (outside diameter 70mm * 300mm), peel off the outer skin with a lathe, and become an ingot with outside diameter φ 65mm. After homogenization heat treatment, the heat treatment temperature is 330 ° C, the holding time is 8 hours, and then cooled to room temperature with the furnace;

[0082] The extrusion die in the extruder was preheated to 150° C., and the extrusion pressure was adjusted to 15 MPa. The extrusion speed is controlled to be 2mm / s. Heat the above-mentioned zinc alloy ingot to 120° C. in an electric heating box for 2 hours. Put it into the mold, start the extruder, and extrude it into a thick bar of 20mm;

[0083] The swaging die in the swaging machine was heated to 180° C., and the above-mentioned hot-extruded bar was put into three passes of heating and swaging. The bar is heated to 220°C by electromagnetic induction. The electromagnetic induction heating frequency is 400Hz, and the feeding speed of the material is 4m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com