Preparation method of In2S3-TiO2/electrospun fiber composite photocatalyst

An electrospinning fiber and catalyst technology, which is applied in the field of preparation of In2S3-TiO2/electrospun fiber composite photocatalyst, can solve the problems of only absorbing ultraviolet light, low utilization rate of sunlight, and narrow light absorption range, and achieves the utilization of light source. The effect of high rate, enhanced interaction ability, and increased hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 0.41g SMA and 3.6g PVDF to the belt stirring and N 2 In a protected three-necked flask, dissolve 14 ml of acetone and 20 ml of DMAC in the three-necked flask, stir and dissolve for 24 hours to obtain a spinning solution.

[0029] (2) The spinning solution obtained in step (1) is prepared in an electrospinning device to obtain a PVDF / SMA electrospun fiber mat, the spinning voltage is 16kv, and the distance between the receiving device and the spinneret is 15-25cm , the flow rate of spinning solution is 0.4ml / h.

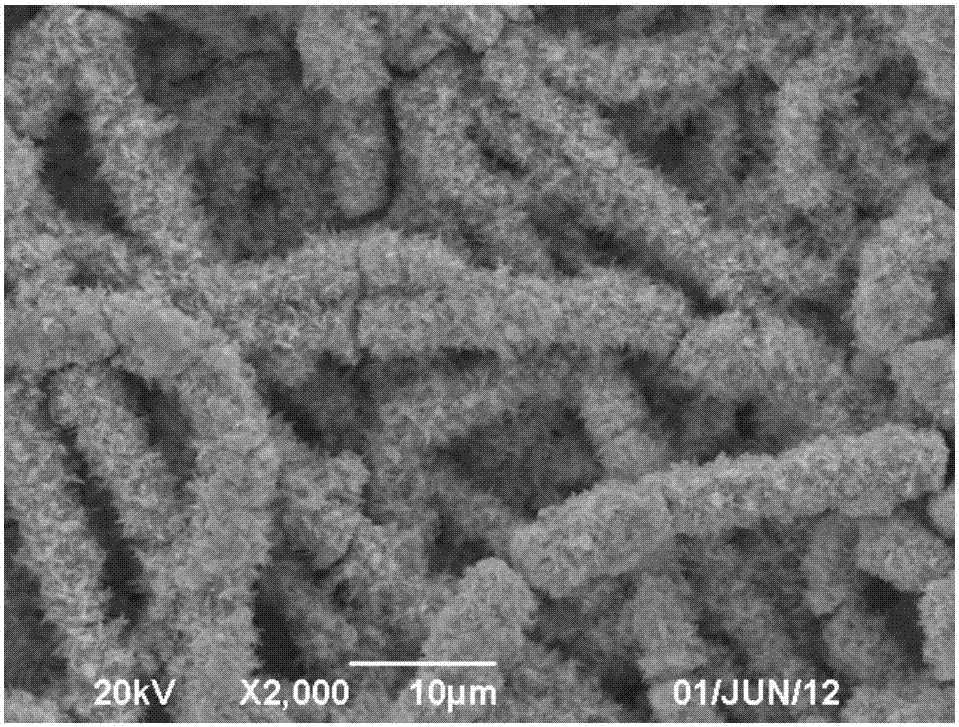

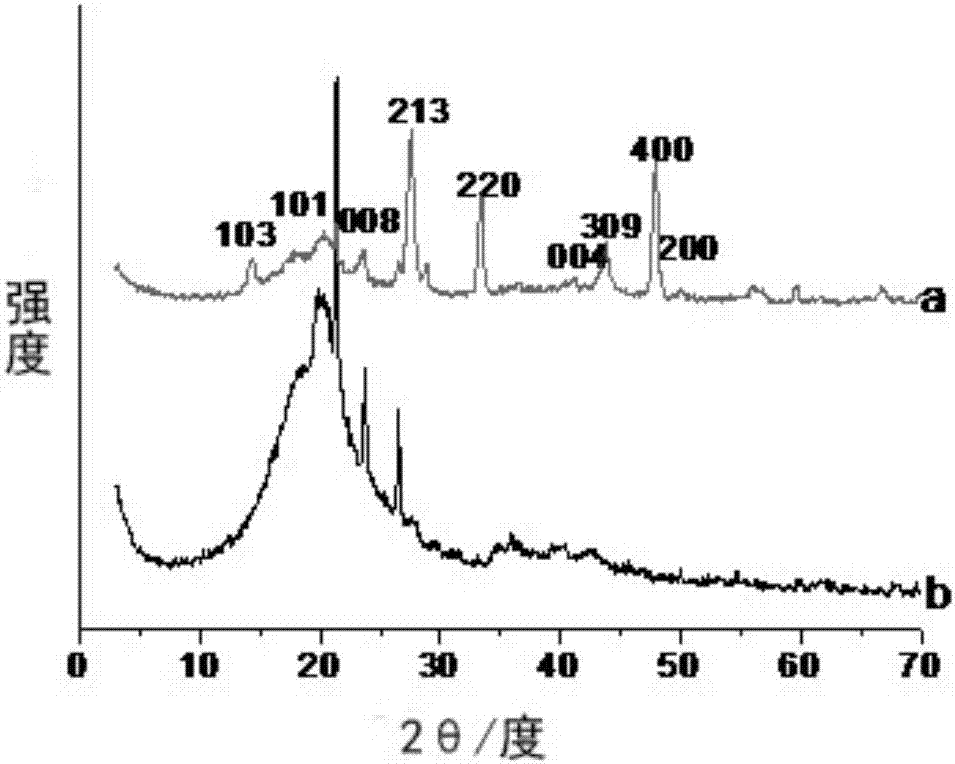

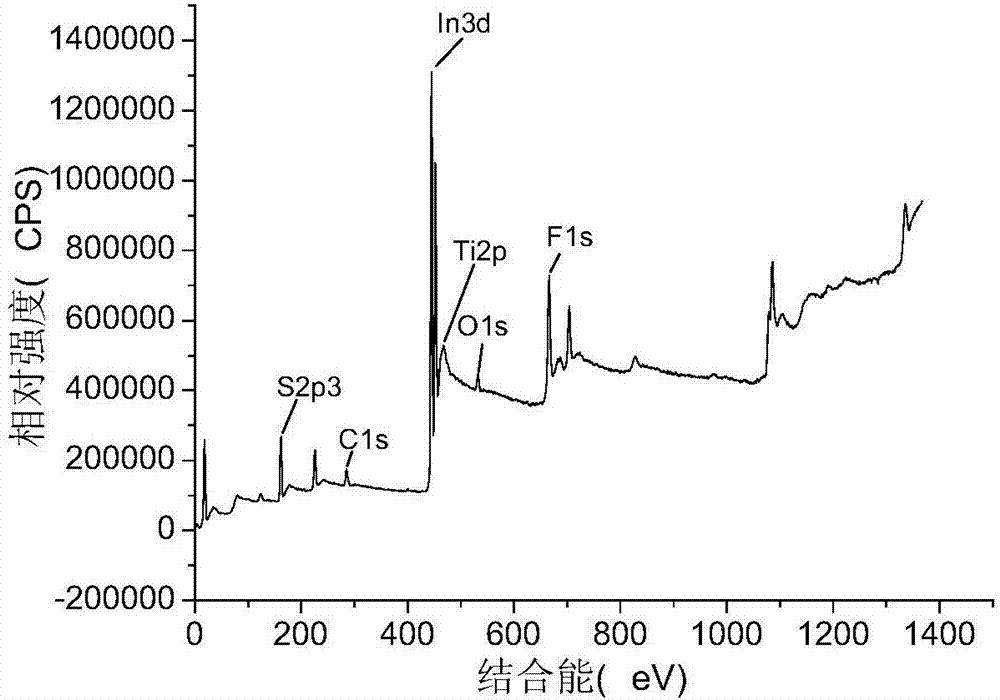

[0030](3) Soak 0.45g of the PVDF / SMA electrospun fiber mat obtained in step (2) into 40ml of 0.25mol / L titanyl sulfate aqueous solution, soak for 24h, place it in a hydrothermal reaction kettle, react at 120°C for 14h, and naturally Cool to room temperature, wash and dry to obtain TiO 2 / Electrospun fiber mat.

[0031] (4) 0.58g TiO obtained in step (3) 2 / Immerse the electrospun fiber in 25ml 0.25mol / L indium nitrate aqueous solution, add 25ml 0.5m...

Embodiment 2

[0033] (1) Add 0.4g SMA and 4.0g PVDF to the belt stirring and N 2 In a protected three-necked flask, dissolve 15ml of acetone and 22ml of DMAC in the three-necked flask, stir and dissolve for 24 hours, and obtain a spinning solution.

[0034] (2) The spinning solution obtained in step (1) is prepared in an electrospinning device to obtain a PVDF / SMA electrospun fiber mat, the spinning voltage is 16kv, and the distance between the receiving device and the spinneret is 15-25cm , the flow rate of spinning solution is 0.4ml / h.

[0035] (3) Soak 0.5g of the PVDF / SMA electrospun fiber mat obtained in step (2) into 50ml of 0.5mol / L titanyl sulfate aqueous solution, soak for 24h, place it in a hydrothermal reaction kettle, react at 120°C for 14h, and naturally Cool to room temperature, wash and dry to obtain TiO 2 / Electrospun fiber mat.

[0036] (4) 0.74g TiO obtained in step (3) 2 / Immerse the electrospun fiber in 25ml 0.5mol / L indium nitrate aqueous solution, add 25ml 0.5mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com