Preparation method of silver phosphate/silver bromide composite photo-catalyst

A technology of composite light and silver bromide, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of expensive, harsh reaction conditions, tedious operation steps, etc., and achieves low production cost, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

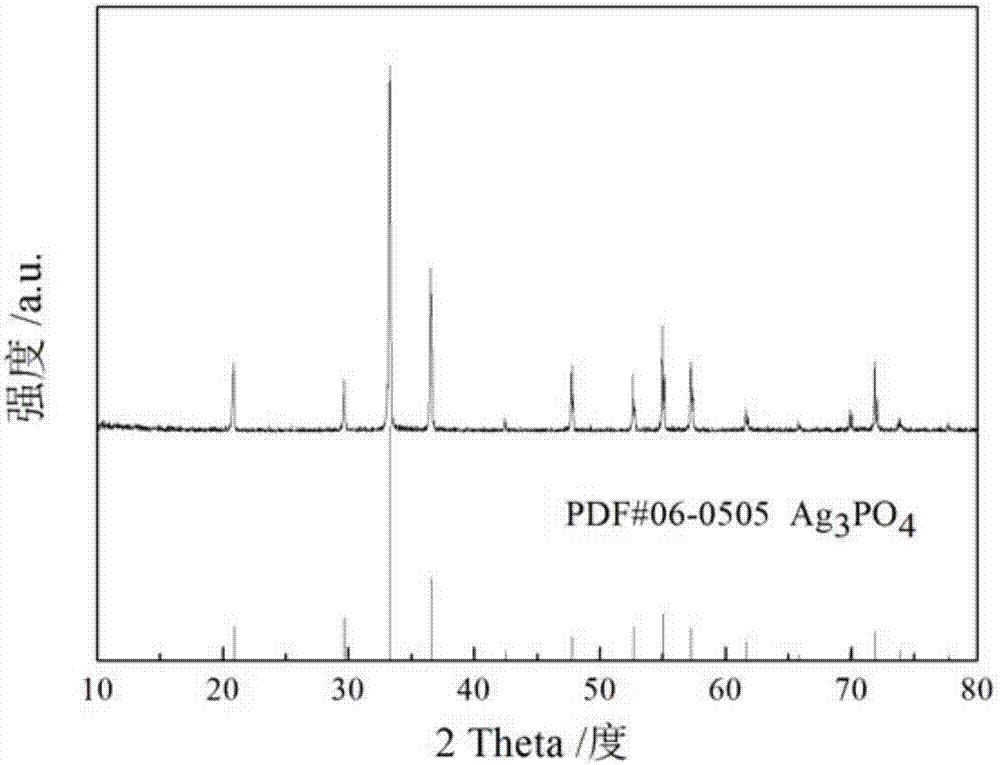

Embodiment 1

[0021] 90mmol 85wt% phosphoric acid was dissolved in 2400mL deionized water, and 75mmol AgNO 3 , dissolved after magnetic stirring. 1125mmol urea was added to the solution, and the solution was magnetically stirred for 30 minutes at room temperature. The solution was transferred to a stainless steel reactor with a tetrafluoroethylene liner, placed in an oven at 80°C, and reacted for 24 hours. After the reaction, cool to room temperature, filter and separate the product with a vacuum pump, wash with deionized water, and dry at 70°C for 12 hours to obtain Ag 3 PO 4 product.

[0022] The photocatalytic property experiment was carried out in a jacketed photocatalytic reactor, using a 500W xenon lamp as the light source (with a 420nm filter), and the light source was perpendicular to the middle of the reactor, 10cm away from the reactor. In the photocatalytic reactor, take 0.2g Ag 3 PO 4 Place in 100mL rhodamine B solution with a concentration of 10.0mg / L, stir magnetically i...

Embodiment 2

[0024] (1)Ag 3 PO 4 preparation of

[0025] Dissolve 90mmol 85% phosphoric acid in 2400mL deionized water, add 75mmol AgNO 3 , dissolved after magnetic stirring. 1125mmol urea was added to the solution, and the solution was magnetically stirred for 30 minutes at room temperature. The solution was transferred to a stainless steel reactor with a tetrafluoroethylene liner, placed in an oven at 80°C, and reacted for 24 hours. After the reaction, cool to room temperature, filter and separate the product with a vacuum pump, wash with deionized water, and dry at 70°C for 12 hours to obtain Ag 3 PO 4 product.

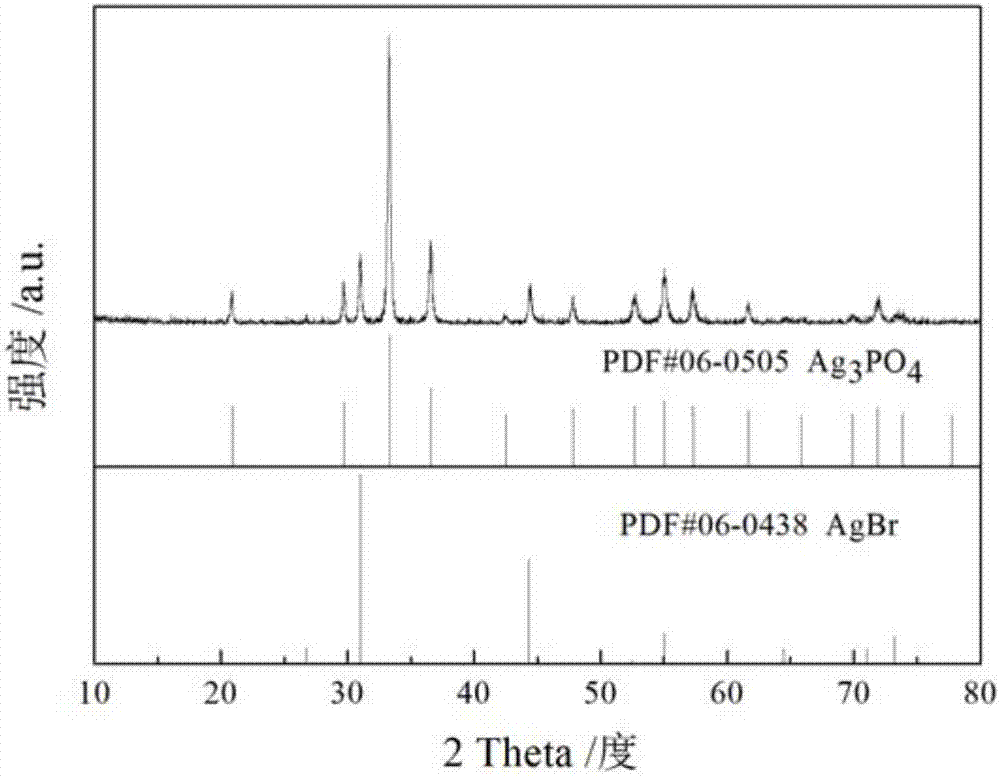

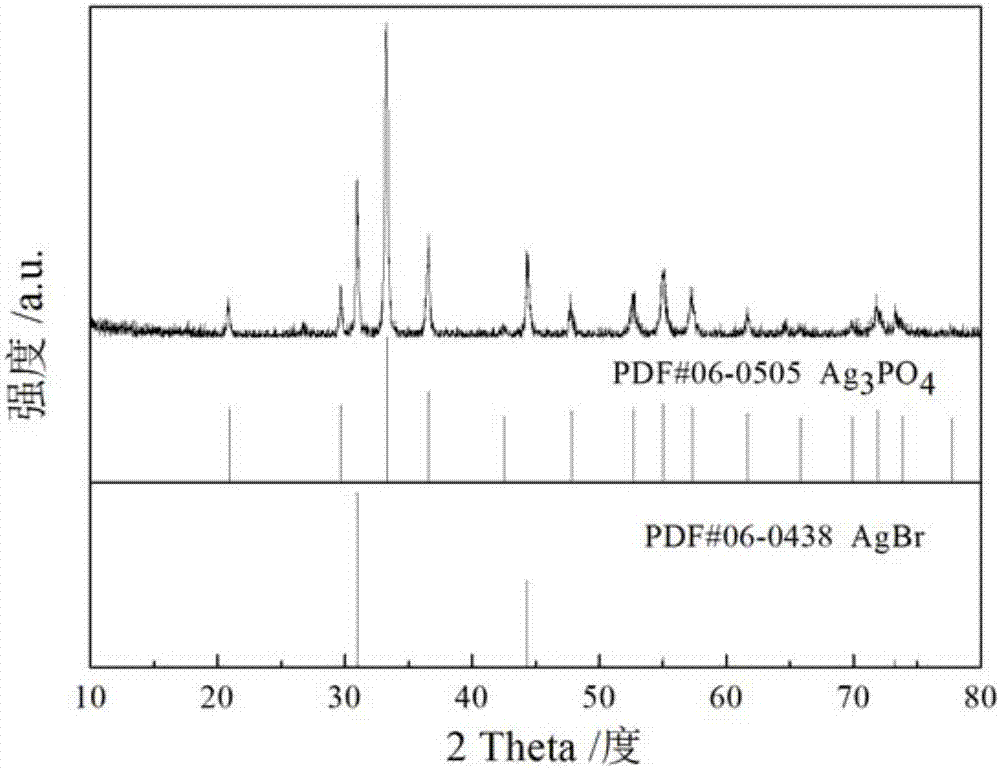

[0026] (2)Ag 3 PO 4 Preparation of / AgBr Composite Photocatalyst

[0027] 4.0 g of Ag at room temperature 3 PO 4 Grind in a ball mill for 10-20 minutes (as shown in Table 1) with a certain mass of NaBr according to different molar ratios (as shown in Table 1), the ball milling speed is 200-300r / min, and the mass ratio of agate balls to raw materials is 2: 1. The atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com