Device used for removing shells of penaeus orientalis

A technology of prawn and spray washing device, which is applied in the processing of crustaceans, shrimp/lobster processing, climate change adaptation, etc. It can solve problems such as low work efficiency, product pollution, and product quality decline, so as to improve processing efficiency and reduce cross-contamination , Guarantee the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

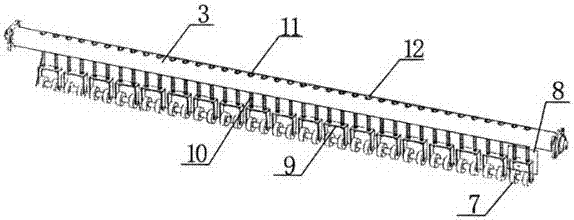

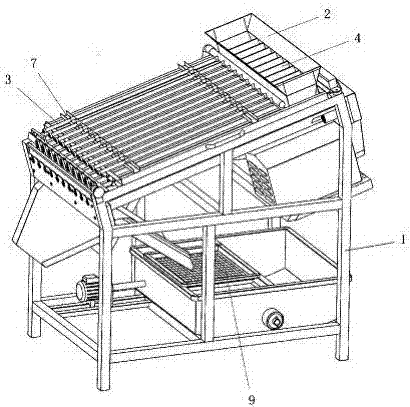

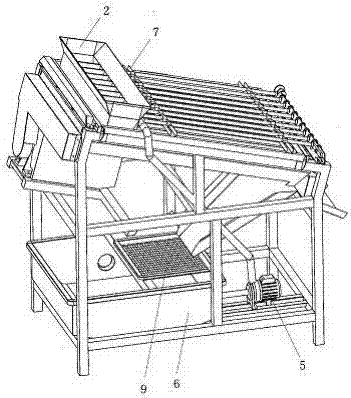

[0024] like figure 1 , figure 2 , a kind of shell removing device, is made of frame 1, grinding shell groove 2, grinding wheel device, transmission mechanism and motor 4, and frame 1 is a cuboid frame structure with one end high and one end low, and above-mentioned grinding shell groove 2 is located at On the frame 1, one end is provided with a feed port 5, and the other end is provided with a discharge port 6, and the bottom surface of the groove is an arc-shaped surface; the above-mentioned grinding wheel device is composed of a roller 3, a telescopic frame 8 and a grinding wheel 7, and the above-mentioned roller Axle 3 is located in the grinding shell groove 2, and above-mentioned multiple telescopic mounts 8 are located on the roller shaft 3, and along the axial direction of the roller shaft, are arranged side by side at intervals; Guide rod 11 is formed, and one end of above-mentioned two guide rods 11 is inserted in the corresponding through-hole 12 on the surface of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com