Automatic assembling equipment of FPC light bars

An automatic assembly and light bar technology, applied in mechanical equipment, metal processing equipment, material gluing, etc., can solve the problems of falling off, manual sticking of FPC light bars, etc., so as to reduce the damage of LED lights and reduce the breaking of FPC light bars. risk, meet the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings of the description.

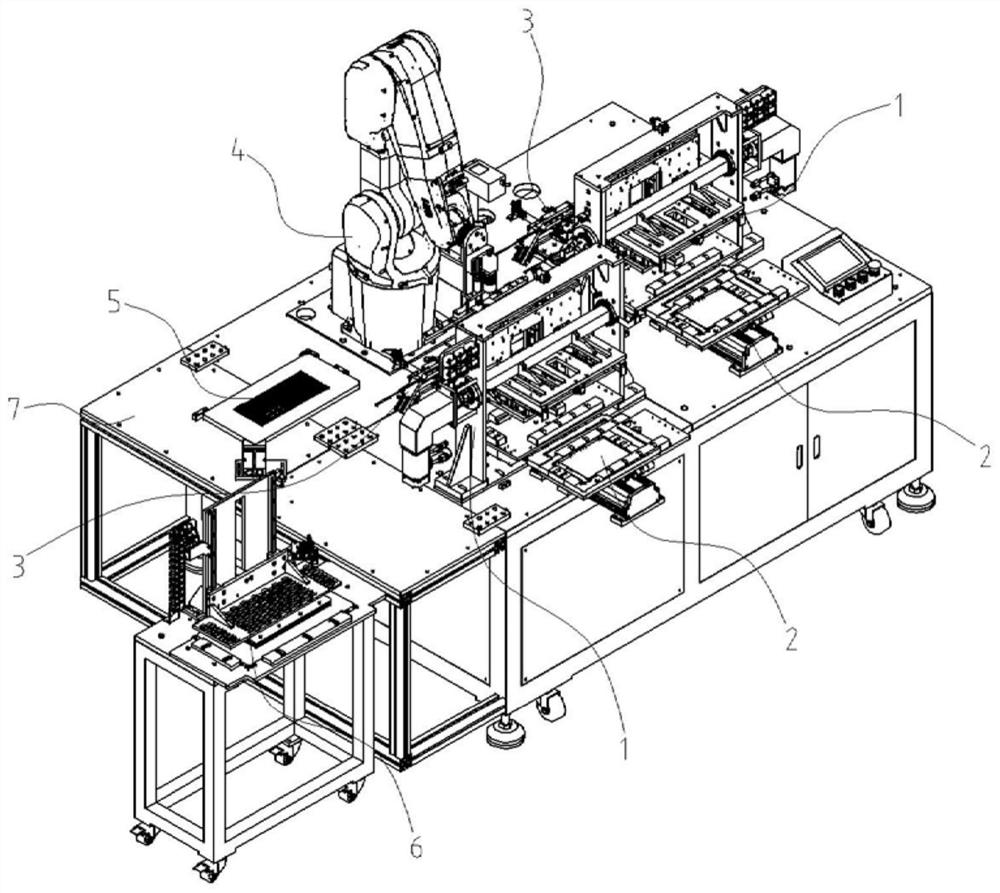

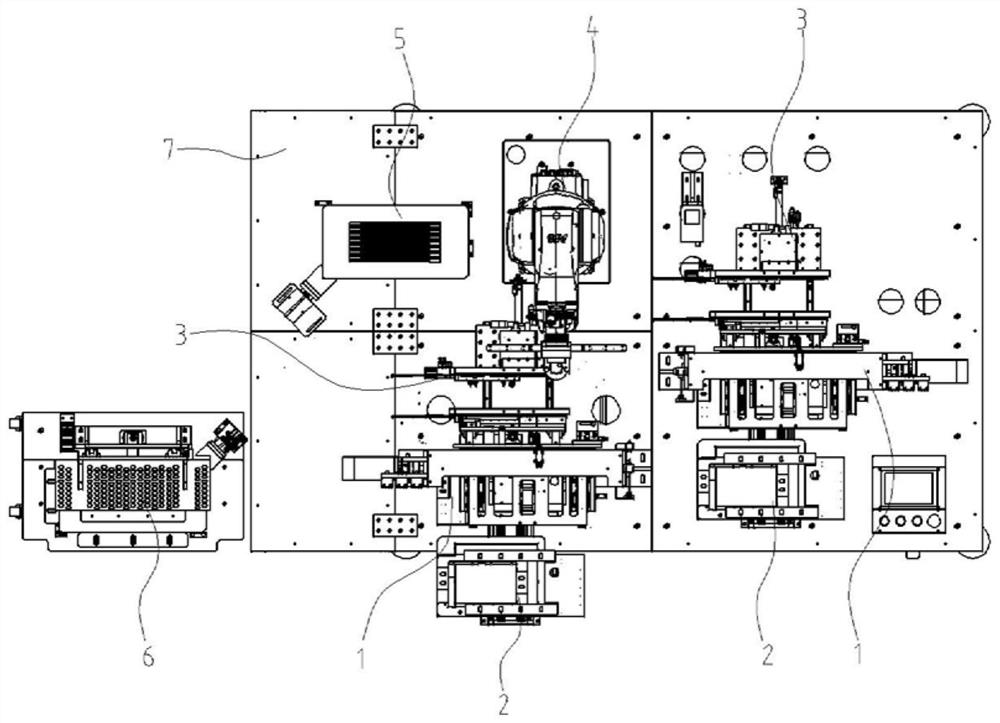

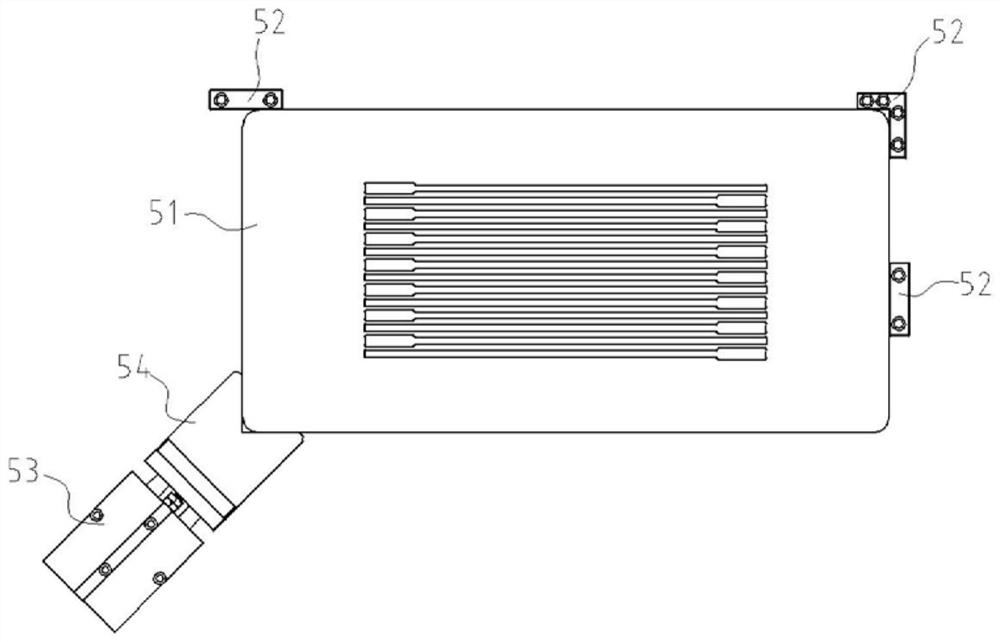

[0038] Such as figure 1 , 2As shown, an automatic assembly equipment for FPC light strips includes a workbench 7, a feeding mechanism 5 for placing FPC light strips 8, a material transfer mechanism 3, a retrieving robot 4, a retrieving and attaching mechanism 1 and an iron Positioning jig 2 for frame loading; retrieving robot 4 transfers FPC light strip 8 from discharge mechanism 5 to transfer mechanism 3, transfer mechanism 3 transfers FPC light strip 8 to retrieving and attaching mechanism 1, and retrieving The attaching mechanism 1 attaches the FPC light bar 8 to the iron frame. The discharging mechanism 5, the transferring mechanism 3, the retrieving robot 4, the retrieving and attaching mechanism 1 and the positioning jig 2 are arranged on the workbench 7, and two groups of transferring mechanisms 3, Two sets of retrieving and attaching mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com