Multisystem cool-heat exchanger and efficient water heating all-in-one machine and working method thereof

A cold and heat exchanger, cold and heat exchange technology, applied in the direction of refrigerators, machine operation methods, refrigeration components, etc., can solve the problems of unable to start operation, low efficiency, low heating efficiency, etc., to improve the efficiency of hot water heating or Effects of heating efficiency, reduction of maintenance rate, and improvement of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

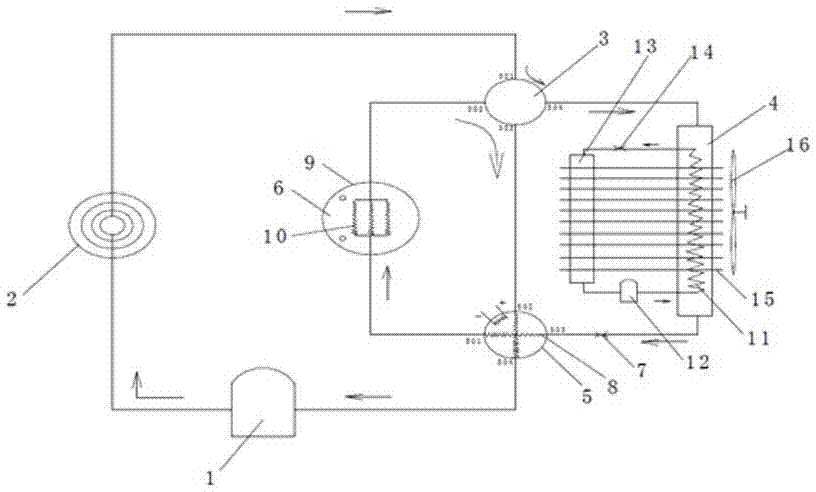

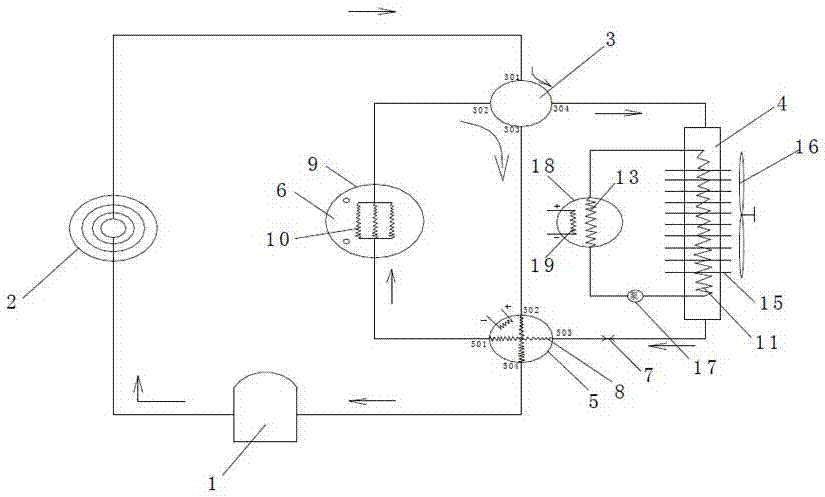

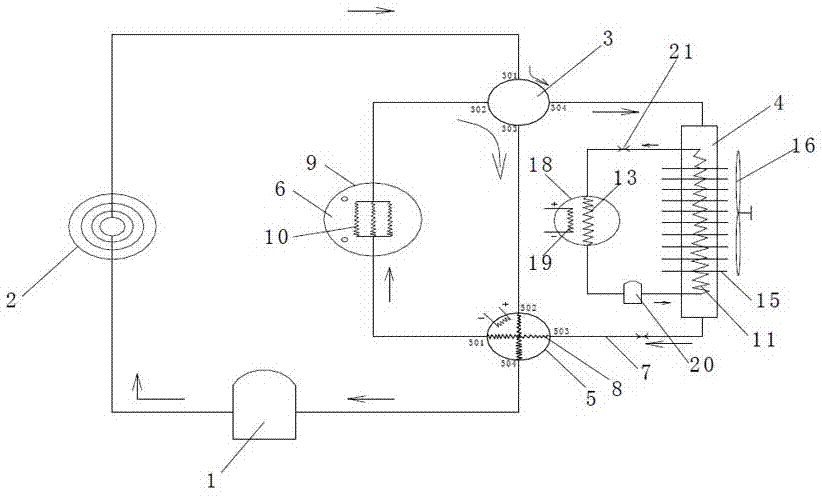

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The multi-system cold and heat exchanger high-efficiency hot water integrated machine of the present invention sequentially includes a compressor 1, a small heating pipe water tank 2, a four-way valve 3, a large cold and heat exchange pipe 4, a cold and heat exchanger 5, and a cold and hot air conditioner 6. The output port of the compressor 1 is connected to the input port of the heating small tube water tank 2, the output port of the heating small tube water tank 1 is connected to the first end 301 of the four-way valve 3, and the second end 302 of the four-way valve is connected to the hot and cold air conditioner The first end of the air conditioner 6, the second end of the hot and cold air conditioner 6 is connected to the first end 501 of the cold and heat exchanger 5, and the third end 303 of the four-way valve is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com