Plate surface film laminating mechanism and plate film laminating machine

A film-coated mechanism and plate technology, applied in the field of mechanical equipment, can solve problems such as self-adjustment of the soldering iron tip, burns, and scratches on the surface of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

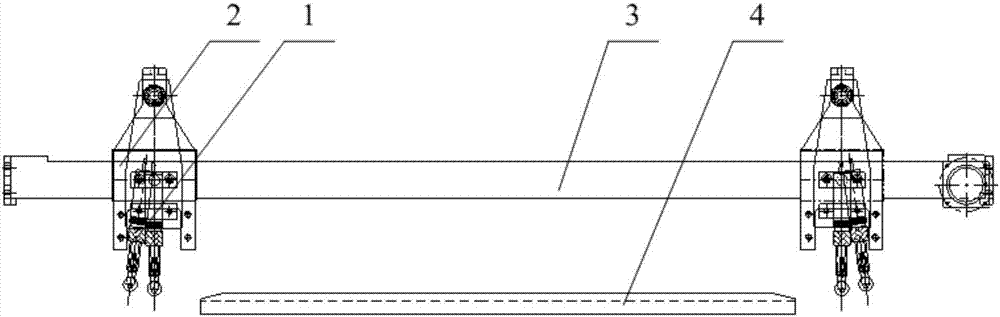

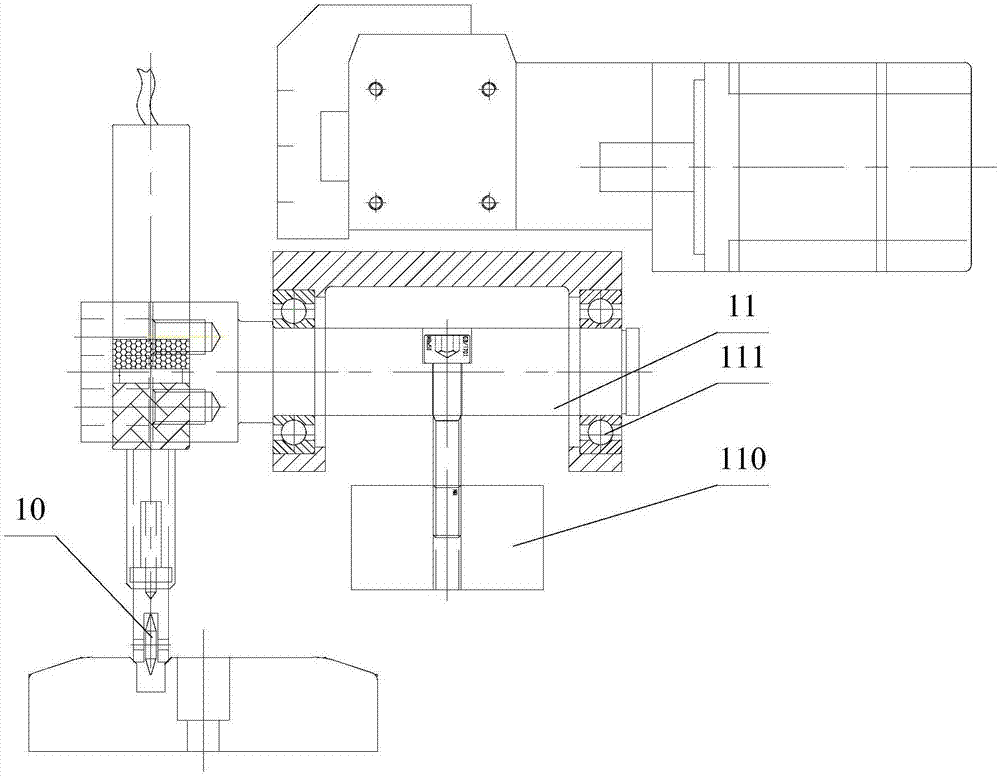

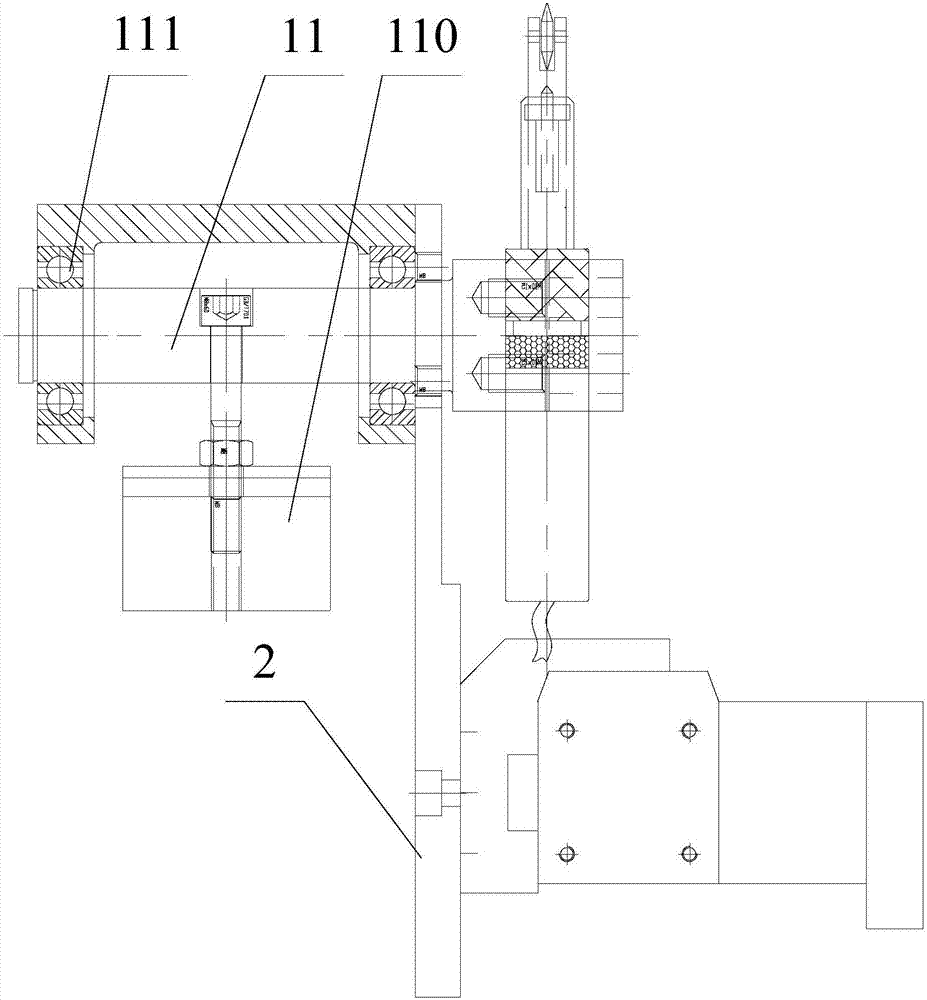

[0034] figure 1 It is a front view of a board surface coating mechanism provided by an embodiment of the present invention, figure 2 It is a front view of an actuator of a plate surface coating mechanism provided by an embodiment of the present invention. Such as figure 1 and 2 As shown, a plate surface coating mechanism provided by the present invention includes: a fixed frame 3, a driving device, a support frame 2 and an actuator 1;

[0035] The support frame 2 is slid on the fixed frame 3;

[0036] The actuator 1 is arranged on the support frame 2, the drive device drives the support frame 2 to move laterally along the fixed frame 3, and the actuator 1 moves along the upper surface of the plate to move the plate The surface coating is scratched.

[0037] Wherein, the positions of the actuator 1 and the support frame 2 can be various. For example, the actuator 1 is arranged inside the support frame 2. To limit the role of actuator 1.

[0038] In addition, the actuato...

Embodiment 2

[0076] A plate coating machine is provided with the above-mentioned plate surface coating mechanism.

[0077] In this embodiment, a board laminating machine with a board surface coating mechanism can improve the accuracy of the board coating and the machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com