Preparation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device preparation, can solve problems such as affecting device performance, scratching word lines, and surface depressions of word lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

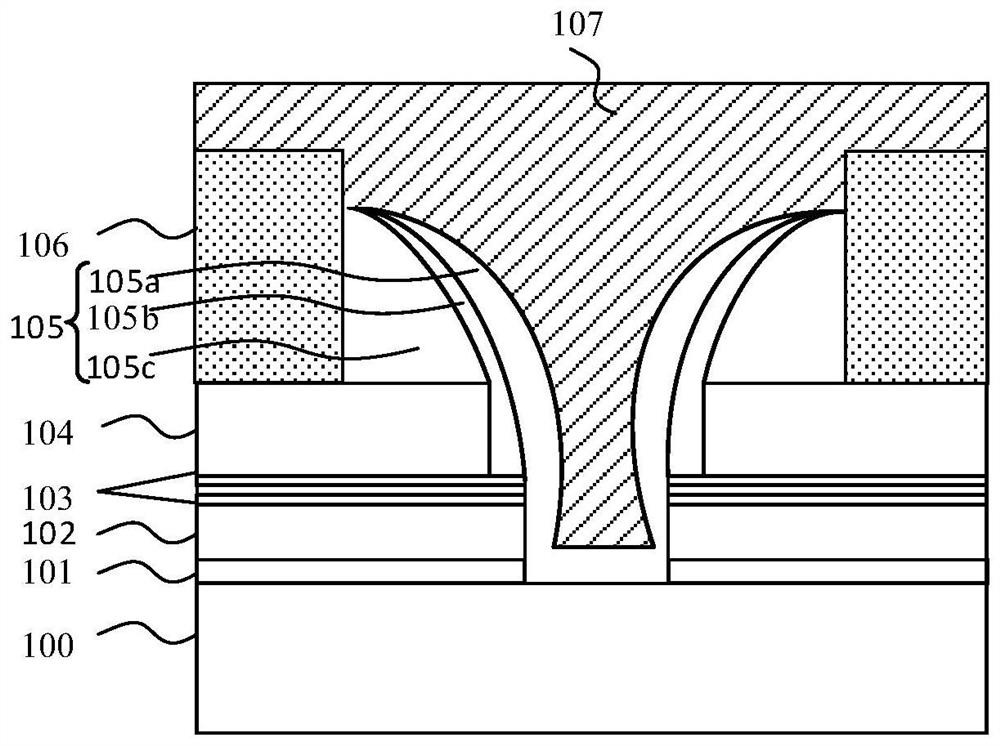

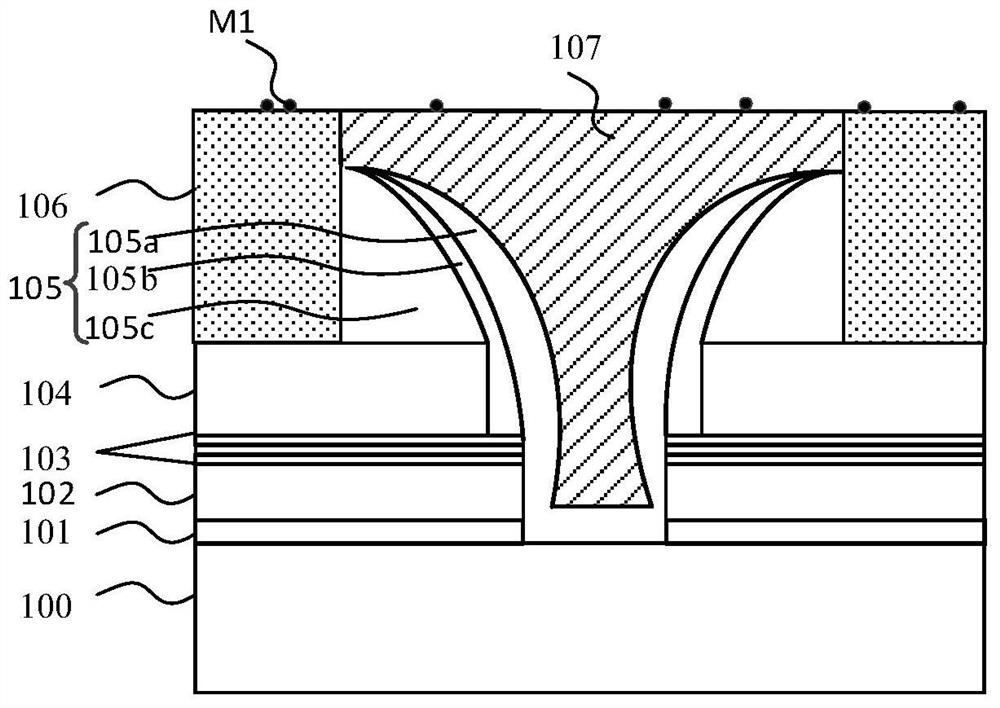

[0025] It can be seen from the above that, in the chemical mechanical polishing process, the longer the polishing time, the more particles will remain in the word line depressions, and there will be some particles caused by polishing on the mask layer. At the same time, long-term grinding will also cause problems such as scratches and dents on the surface of the word lines, thereby affecting the subsequent preparation process.

[0026] Therefore, there is a need for a new method for preparing a semiconductor device, which can solve the problem of material particle residues and scratches on the surface of the substrate caused by the chemical mechanical polishing process on the word line on the basis of ensuring the height setting of the word line. Problems such as scratches and dents can be avoided, so as to ensure the normal progress of subsequent processes and improve the performance of semiconductor devices.

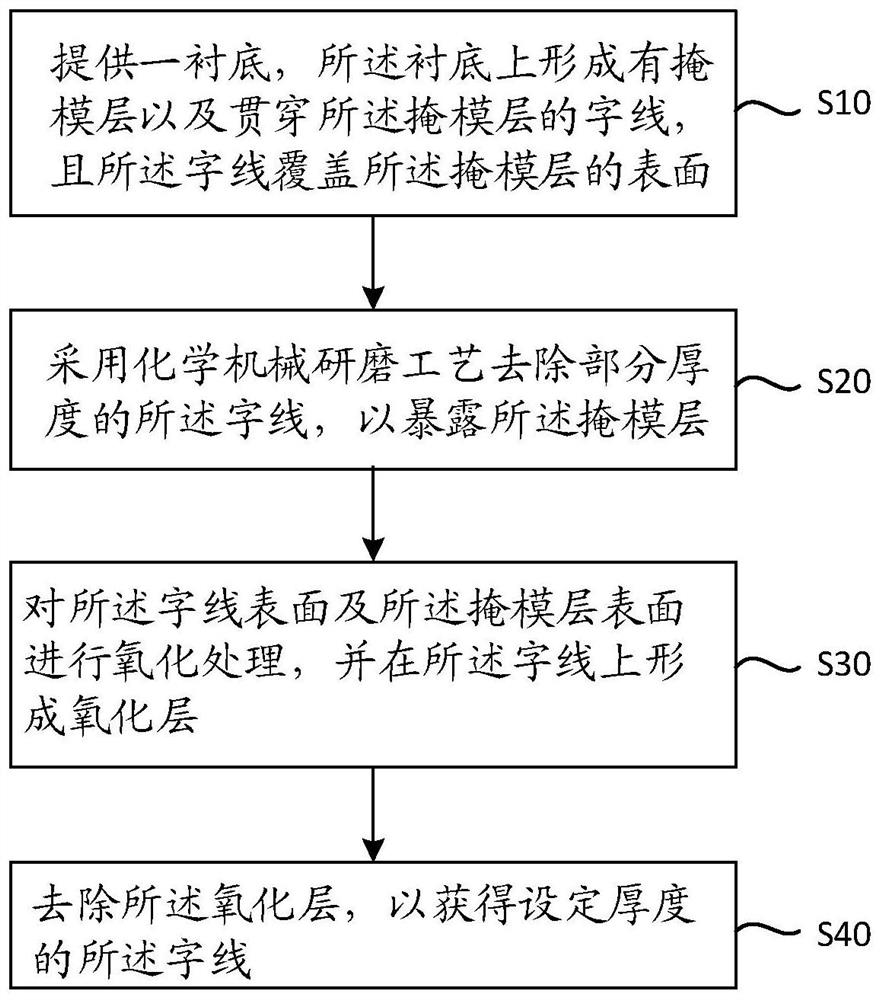

[0027] A method for manufacturing a semiconductor device proposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com