Preparation method of SQRTM forming process carbon fiber grating based on water-soluble core

A water-soluble core and molding technology, applied in other home appliances, home appliances, household components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

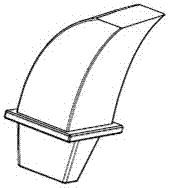

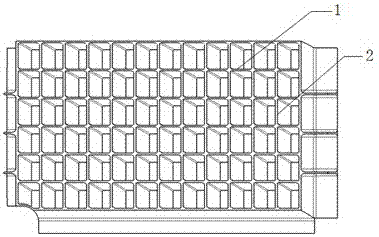

[0030] Embodiment 1: as Figure 1~2 As shown, the preparation method of the grid based on the SQRTM molding process of the water-soluble core may further comprise the steps:

[0031] (1) Preparation of the soluble mandrel: first put the soluble mandrel material into the mandrel cavity, and compact the soluble mandrel material through the mold fastening bolts; then put it into an oven for curing, the curing temperature is: 120°C, The curing time is 2 hours, cool to below 60°C and open the oven to take it out; the mandrel after drying and molding is as follows: figure 1 As shown, in order to ensure the surface smoothness of the workpiece, the surface of the molded mandrel is sealed with a surface sealant, and the composite material is laid in the later stage;

[0032] (2) Carry out carbon fiber prepreg paving on the water-soluble mandrel, adopt SQRTM (Same Qualified Resin Transfer Molding) molding process to cure the part, and make the grid part;

[0033] (3) Dissolve the wate...

Embodiment 2

[0039] Embodiment 2: the preparation method of the grid based on the SQRTM molding process of this water-soluble core, comprises the following steps:

[0040] (1) Preparation of soluble mandrel: first put the soluble mandrel material (gypsum) into the mandrel cavity, and compact the soluble mandrel material through the mold fastening bolts; then put it into an oven for curing, and the curing temperature is: 100°C, curing time is 3h, cool down to below 60°C and open the oven to take out; the core mold after drying is as follows figure 1 As shown, in order to ensure the surface smoothness of the workpiece, the surface of the molded mandrel is sealed with a surface sealant, and the composite material is laid in the later stage;

[0041] (2) Carry out carbon fiber prepreg paving on the water-soluble mandrel, adopt SQRTM (Same Qualified Resin Transfer Molding) molding process to cure the part, and make the grid part;

[0042] (3) Dissolve the water-soluble mandrel with tap water, ...

Embodiment 3

[0047] Embodiment 3: the preparation method of the grid of the SQRTM molding process based on the water-soluble core, comprises the following steps:

[0048] (1) Preparation of soluble mandrel: firstly put the soluble mandrel material (soluble silicate) into the mandrel cavity, and compact the soluble mandrel material through the mold fastening bolts; then put it into the oven for curing, curing The temperature is: 140°C, the curing time is 1h, cool down to below 60°C, open the oven and take it out; the core mold after drying and forming is as follows: figure 1 As shown, in order to ensure the surface smoothness of the workpiece, the surface of the molded mandrel is sealed with a surface sealant, and the composite material is laid in the later stage;

[0049] (2) Carry out carbon fiber prepreg paving on the water-soluble mandrel, adopt SQRTM (Same Qualified Resin Transfer Molding) molding process to cure the part, and make the grid part;

[0050] (3) Dissolve the water-solubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com