Machining method of high-precision local ultra-high current printed circuit board

A printed circuit board, high-precision technology, used in printed circuits, printed circuit manufacturing, multi-layer circuit manufacturing, etc., can solve the problems of excessive ink thickness, excessive line width tolerance, thin ink thickness, etc., to achieve production. The effect of smooth process, increased order-taking ability, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

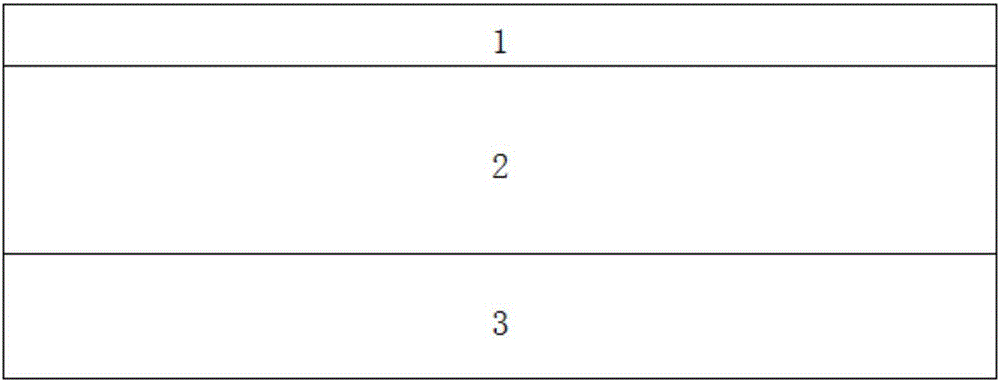

[0009] See attached figure 1 , is a high-precision local ultra-high current printed circuit board made by the method of the present invention, that is, a yin-yang copper thick printed circuit board structure, including a substrate 2 and thin copper layers respectively arranged on both sides of the substrate 1 and thick copper layer 3. When making the outer layer circuit of this board, first paste the dry film on both sides, and use the parallel exposure and development on the first side of the thin copper layer, and use the black film to fully expose and develop on the third side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com