Mixed laminating board with three-layer HDI (high density interconnect) board and aluminum substrate and manufacturing method thereof

A production method and technology for aluminum substrates, which are applied in the directions of multi-layer circuit manufacturing, printed circuit manufacturing, and conductive pattern layout details, etc., can solve the problems of difficult production of mixed-press boards, product quality and precision need to be improved, etc., so as to reduce the production difficulty, Improve the precision of the finished product and avoid the effect of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a mixed laminate of three-layer HDI board and aluminum substrate and its manufacturing method. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

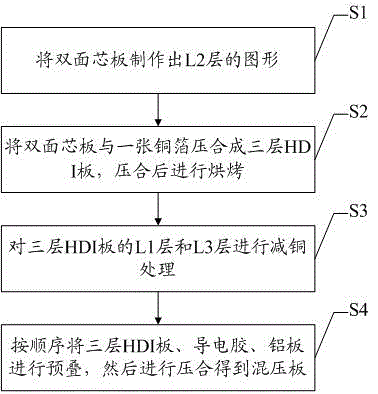

[0025] see figure 1 , figure 1 It is a flow chart of a preferred embodiment of a method for manufacturing a mixed laminate based on a three-layer HDI board and an aluminum substrate in the present invention, as shown in the figure, which includes steps:

[0026] S1, making the double-sided core board into the graphics of the L2 layer;

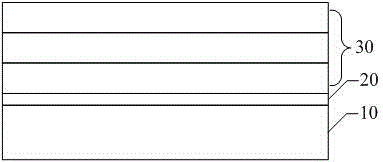

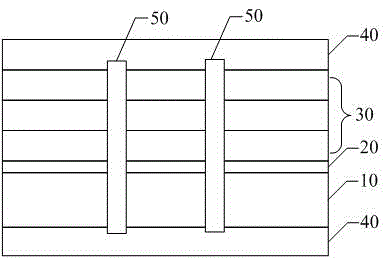

[0027] S2. Laminate the graphic side of the double-sided core board with the copper foil to form a three-layer HDI board, and bake after lamination;

[0028] S3, carry out copper reducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com