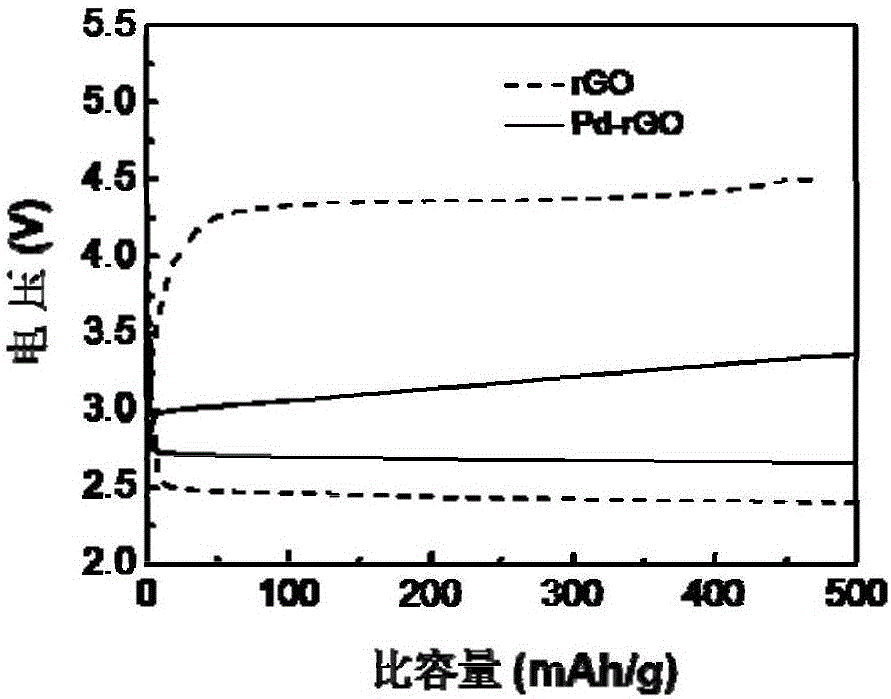

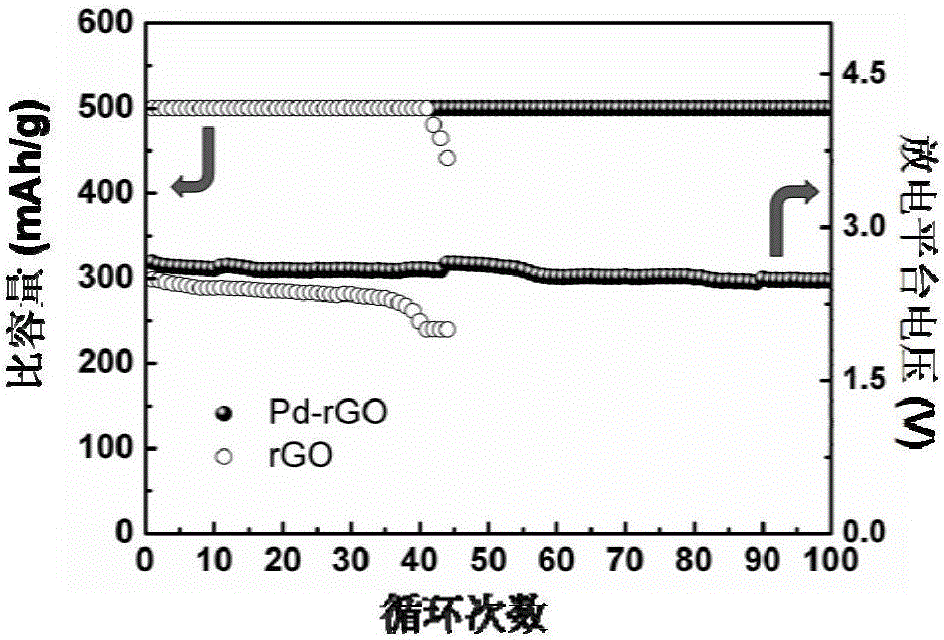

Preparation method of low polarization lithium-air battery cathode catalytic material

A technology of air batteries and catalytic materials, applied in the field of electrochemistry, can solve the problems of large-scale commercialization of catalysts, high cost, and high price, and achieve the effects of controlling cost and large-scale production, good repeatability of results, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the low polarization lithium-air battery cathode catalyst material proposed by the present invention comprises the following steps:

[0015] (1) 15 mL of graphene oxide solution with a concentration of 5 to 10 mg / mL obtained by the Hummers method (J.Am.Chem.Soc. 1958, 80, 1339) or 15 mL with a concentration of 5 to 10 mg / mL obtained by the Hummers method The oxidized carbon nanotube solution was added to 60mL of deionized water to dilute, ultrasonically treated for 30 minutes, and dispersed evenly; then 5mL of palladium chloride (PdCl 2 ) aqueous solution or 5 mL of ruthenium trichloride hydrate (RuCl 3 ·3H 2 0), sonicated for 15 minutes to disperse evenly, stirred for 8 to 12 hours to obtain a homogenate; 5 mL of hydrazine hydrate solution with a mass percent concentration of 70 to 85% was added dropwise to the stirred homogenate, stirred for 15 minutes, and Put it into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and...

Embodiment 1

[0020] (1) Add 15 mL of 5 mg / mL graphene oxide solution obtained by the Hummers method into 60 mL of deionized water for dilution, and disperse evenly by ultrasonication for 30 min. Then add 5 mL of 1.5 mg / mL PdCl 2 aqueous solution. Ultrasound for 15 minutes to disperse evenly, and stir for 8 to 12 hours. 5mL of 70-85% hydrazine hydrate solution was added dropwise to the stirred homogenate, stirred for 15 minutes, and then transferred to a hydrothermal reaction kettle with a polytetrafluoroethylene liner. Reaction at 160℃~180℃ for 10~14 hours

[0021] (2) The product obtained by the hydrothermal reaction is repeatedly washed with water and filtered until the filtrate is neutral (PH test paper detection), and then the washed product is dried in a vacuum freeze dryer for at least 24 hours to completely dehydrate

[0022] (3) At a heating rate of 5 °C / min, the temperature was raised to 450 °C under the protection of flowing nitrogen, and the dried product was annealed for 2.5...

Embodiment 2

[0024] (1) Add 15 mL of 5 mg / mL graphene oxide solution obtained by the Hummers method into 60 mL of deionized water for dilution, and disperse evenly by ultrasonication for 30 min. Then add 5 mL of 2.3 mg / mL RuCl 3 ·3H 2 O aqueous solution. Ultrasound for 15 minutes to disperse evenly, and stir for 8 to 12 hours. 5mL of 70-85% hydrazine hydrate solution was added dropwise to the stirred homogenate, stirred for 15 minutes, and then transferred to a hydrothermal reaction kettle with a polytetrafluoroethylene liner. Reaction at 160℃~180℃ for 10~14 hours

[0025] (2) The product obtained by the hydrothermal reaction is repeatedly washed with water and filtered until the filtrate is neutral (PH test paper detection), and then the washed product is dried in a vacuum freeze dryer for at least 24 hours to completely dehydrate

[0026](3) At a heating rate of 5 °C / min, the temperature was raised to 400 °C under the protection of flowing nitrogen, and the dried product was annealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com