Preparation method of polymer coated lithium ion battery electrode material

An electrode material and ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsatisfactory coating effect, poor stability of conductive polymers, etc., to achieve inhibition of active lithium consumption, chemical and electrochemical stability Good performance and low impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the polymer-coated lithium-ion battery electrode material of the present invention comprises the following steps: (a) dissolving fluorine-containing or chlorine-containing polyolefin in an organic solvent to form a polymer solution; (b) immersing the inorganic electrode material in the (c) heat-treat the product of step (b) under vacuum or inert gas conditions, and the heat-treatment temperature is 100-220°C. The polymer polymer is coated on the surface of the lithium-ion battery electrode material by the liquid phase impregnation method, and a thin and dense polymer coating layer is formed on the surface of the material. After heat treatment at an appropriate temperature, the coating layer is in the conventional It is insoluble in the slurry dispersant (water and N-methylpyrrolidone) and will not be destroyed in the subsequent slurrying process; the polymer coating helps to release the inner electrode material due to volume expansion and contra...

Embodiment 1

[0025] The present embodiment provides a kind of preparation method of polymer-coated lithium-ion battery electrode material, and it comprises the following steps:

[0026] (a) Dissolve 5g of PVF in 95g of N, N dimethylformamide, heat and stir to make a concentration of 5wt% PVF solution;

[0027] (b) Add 10g lithium nickel manganese oxide powder to the above solution, utilize high-speed mechanical stirring to make the material completely soaked in the solution, and filter and separate the lithium nickel manganese oxide material;

[0028] (c) then placed in a vacuum oven, dried at 140° C. for 12 hours, to remove the residual solvent component of step (b), and at the same time make the coating layer closely contact with the surface of the active material;

[0029] (d) Repeat step (b) and step (c) once each;

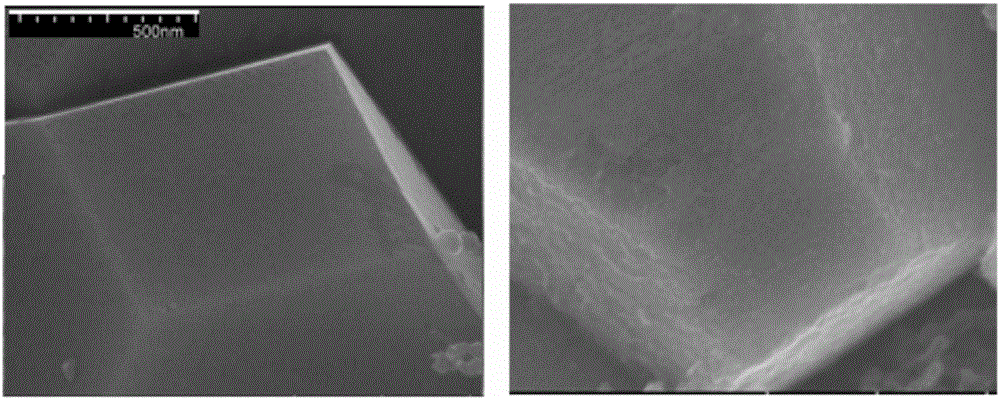

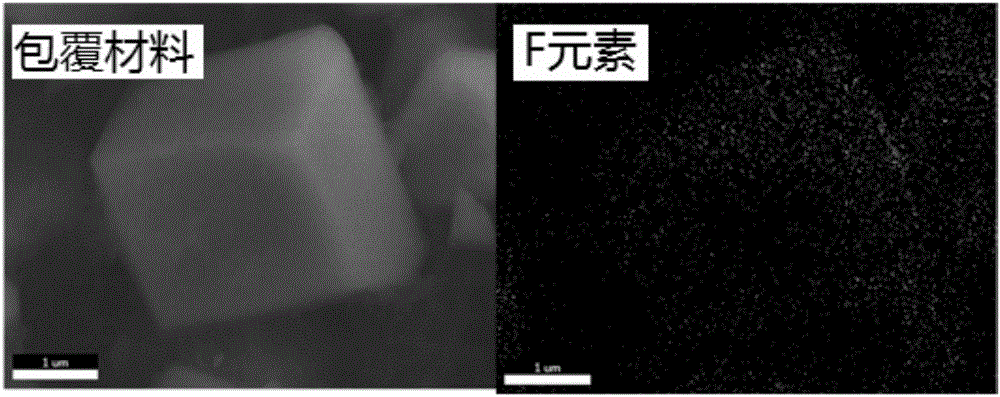

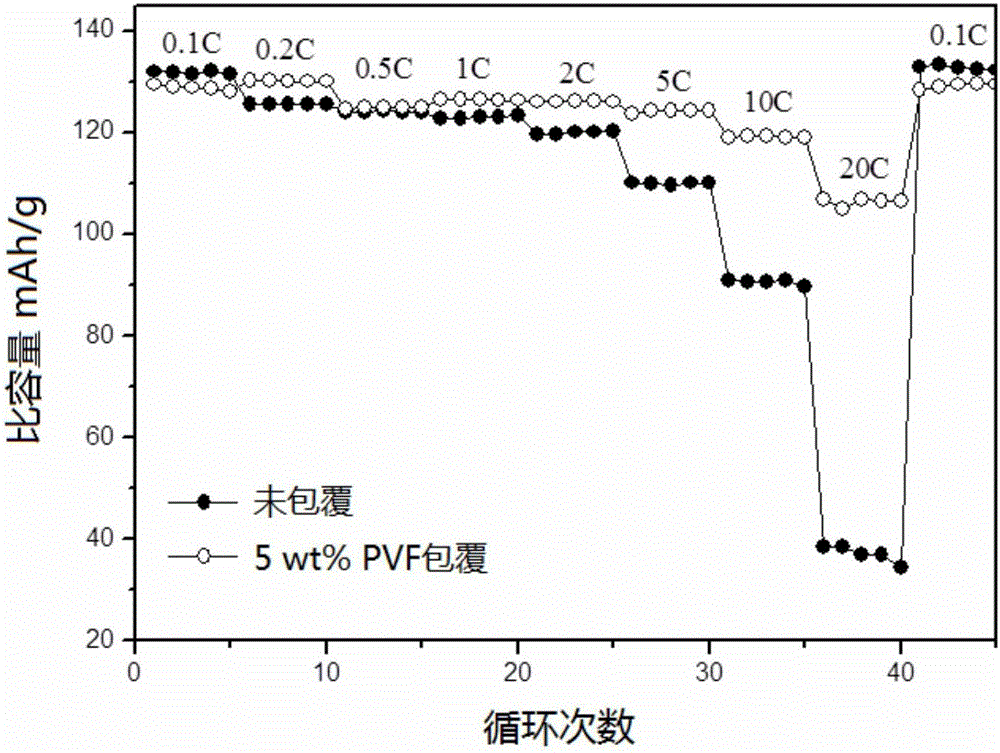

[0030] The SEM image and EDX image of the coated lithium nickel manganese oxide material are as follows respectively figure 1 and figure 2 As shown, it can be seen tha...

Embodiment 2

[0033] This embodiment provides a preparation method of a polymer-coated lithium-ion battery electrode material. Its preparation steps are basically the same as those in Example 1, except that the concentration of the polymer used is 1 wt%, so that the coating layer The mass percentage is about 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com