Secondary battery

A secondary battery and electrolyte technology, applied in the direction of secondary battery, secondary battery repair/maintenance, battery pack parts, etc. The effect of preventing thermal runaway and reducing closed-cell temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application will be further elaborated below in conjunction with specific embodiments. It should be understood that these examples are only used to illustrate the present application and are not intended to limit the scope of the present application.

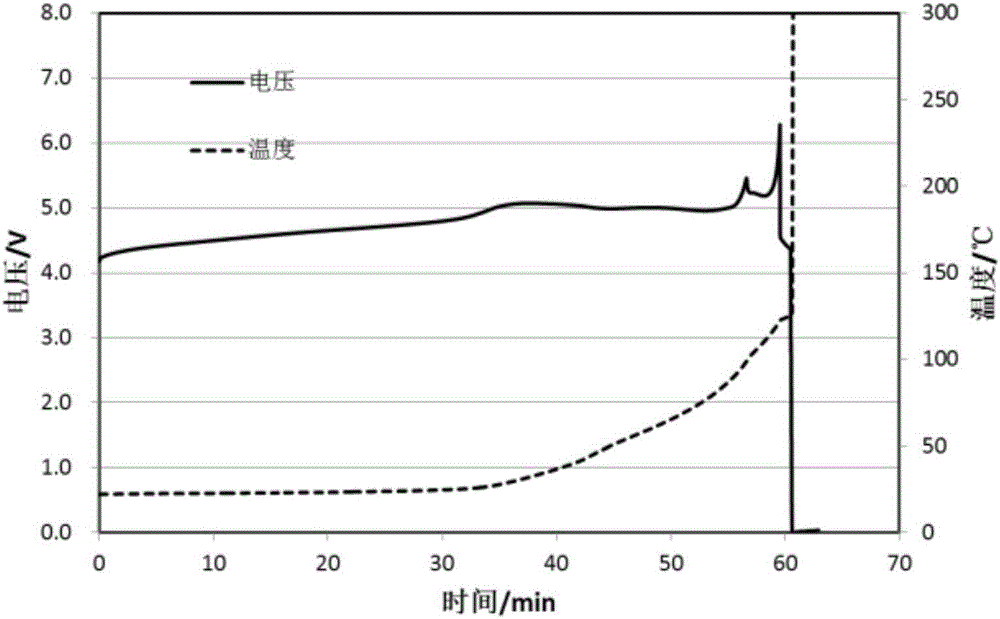

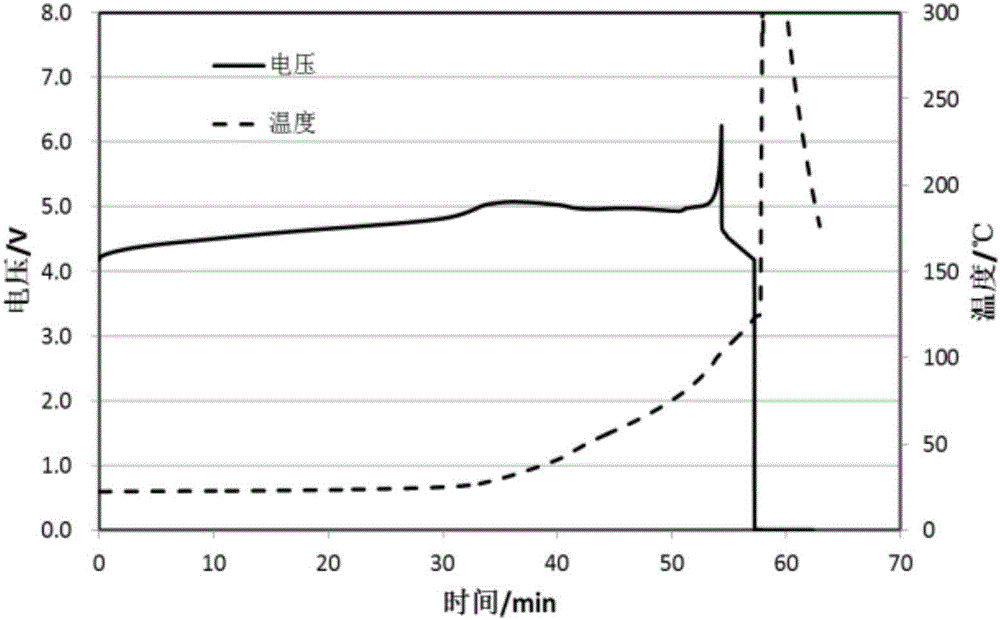

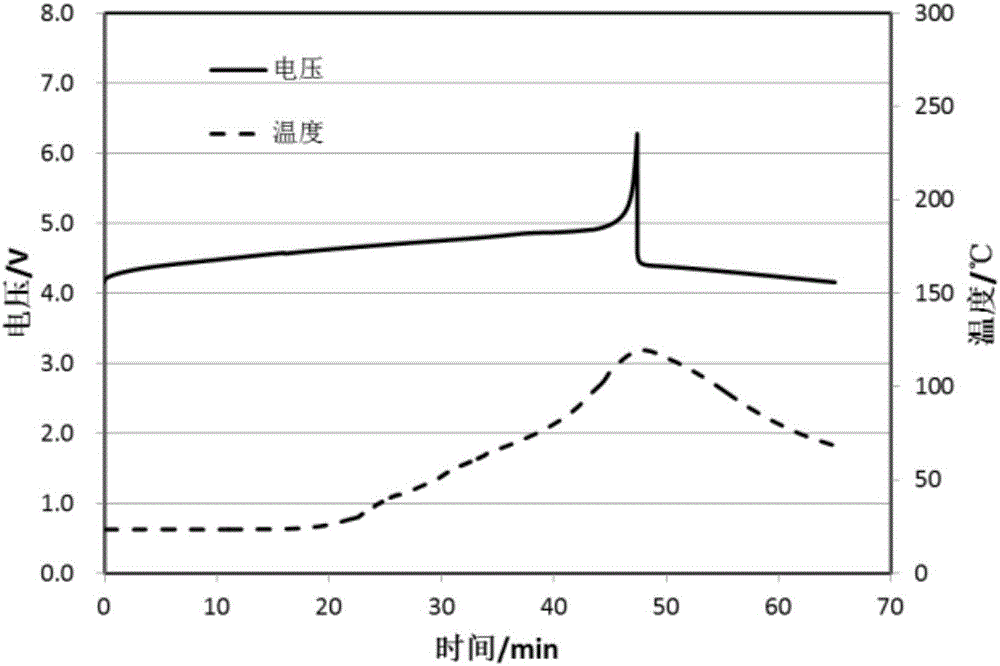

[0038] The application relates to a secondary battery, including a positive pole piece, a negative pole piece, a diaphragm and an electrolyte. The diaphragm of the present application is a composite diaphragm, including a diaphragm matrix and a coating arranged on the surface of the diaphragm matrix. The coating contains polymer The softening temperature of the microspheres and polymer microspheres is 50-120°C; meanwhile, the electrolyte of the secondary battery of the present application contains additives, and the decomposition voltage of the additives is 4.4V-4.8V.

[0039]The additive in this application refers to an additive that undergoes a chemical reaction at a specific voltage and releases heat, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com