A kind of tebuconazole molecularly imprinted membrane electrode, portable sensor and its use method and application

A technology of molecularly imprinted membrane and tebuconazole, applied in instruments, scientific instruments, analytical materials, etc., can solve the problems of contaminated sample test results, inaccurate test results, complicated operation, etc., achieve fast and accurate on-site detection, and improve sensitivity and accuracy, the effect of amplifying the response signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

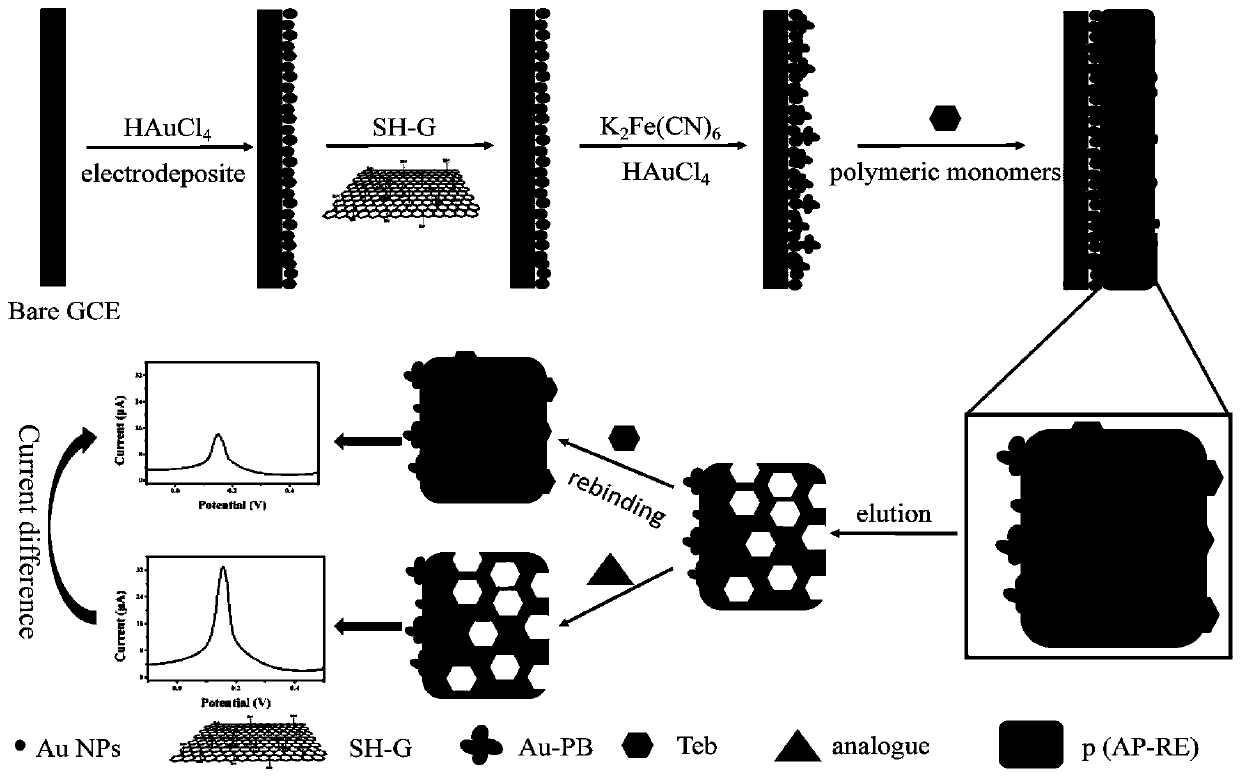

[0048] The present invention provides a method for preparing a tebuconazole molecularly imprinted membrane electrode described in the above technical solution, comprising the following steps:

[0049] (1) placing the substrate electrode in a tetrachloroalloy acid solution, performing electrodeposition by a constant potential method, depositing gold nanoparticles on the surface of the substrate electrode, and obtaining a gold nanoparticle modified electrode;

[0050] (2) The gold nanoparticle modified electrode obtained in the step (1) is left standing in the aqueous solution of mercaptographene, so that the mercaptographene is modified on the gold nanoparticle surface of the electrode to obtain the mercaptographene-gold nanoparticle modification electrode;

[0051] (3) The mercaptographene-gold nanoparticle modified electrode obtained in the step (2) is placed in a mixed solution containing potassium nitrate, tetrachloroalloy acid and potassium ferrocyanide, and gold-nanoparti...

Embodiment 1

[0101] Soak the glassy carbon electrode in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 1:3 for 20 minutes, and use 0.05 μm Al 2 o 3 Grind and polish until the surface of the electrode is mirror-like, wash it with water, and ultrasonicate it in water for 10 minutes. Dry the electrode after ultrasonication with nitrogen, place it in 0.5 mol / L dilute sulfuric acid solution, and scan 20 cycles in the voltage range of -0.2 ~ 1.6V by cyclic voltammetry. After scanning, the electrode was washed with water and dried with nitrogen to obtain the pretreated substrate electrode.

[0102] Place the pretreated substrate electrode in 3mmol / L tetrachloroalloy acid solution, and use the constant potential method to electrodeposit at a voltage of -0.2V for 100s, so that gold nanoparticles are deposited on the surface of the substrate electrode to obtain a gold nanoparticle modified electrode. .

[0103] The gold nanoparticle-modified electr...

Embodiment 2

[0109] The base electrode was placed in 2.5mmol / L tetrachloroalloy acid solution, and the electrodeposition was carried out at -0.1V for 80s by the constant potential method, so that the gold nanoparticles were deposited on the surface of the base electrode, and the gold nanoparticles modified electrode was obtained.

[0110] The gold nanoparticle-modified electrode was placed in a 0.25 mg / mL mercaptographene aqueous solution, and allowed to stand for 2 hours to obtain a mercaptographene-gold nanoparticle-modified electrode.

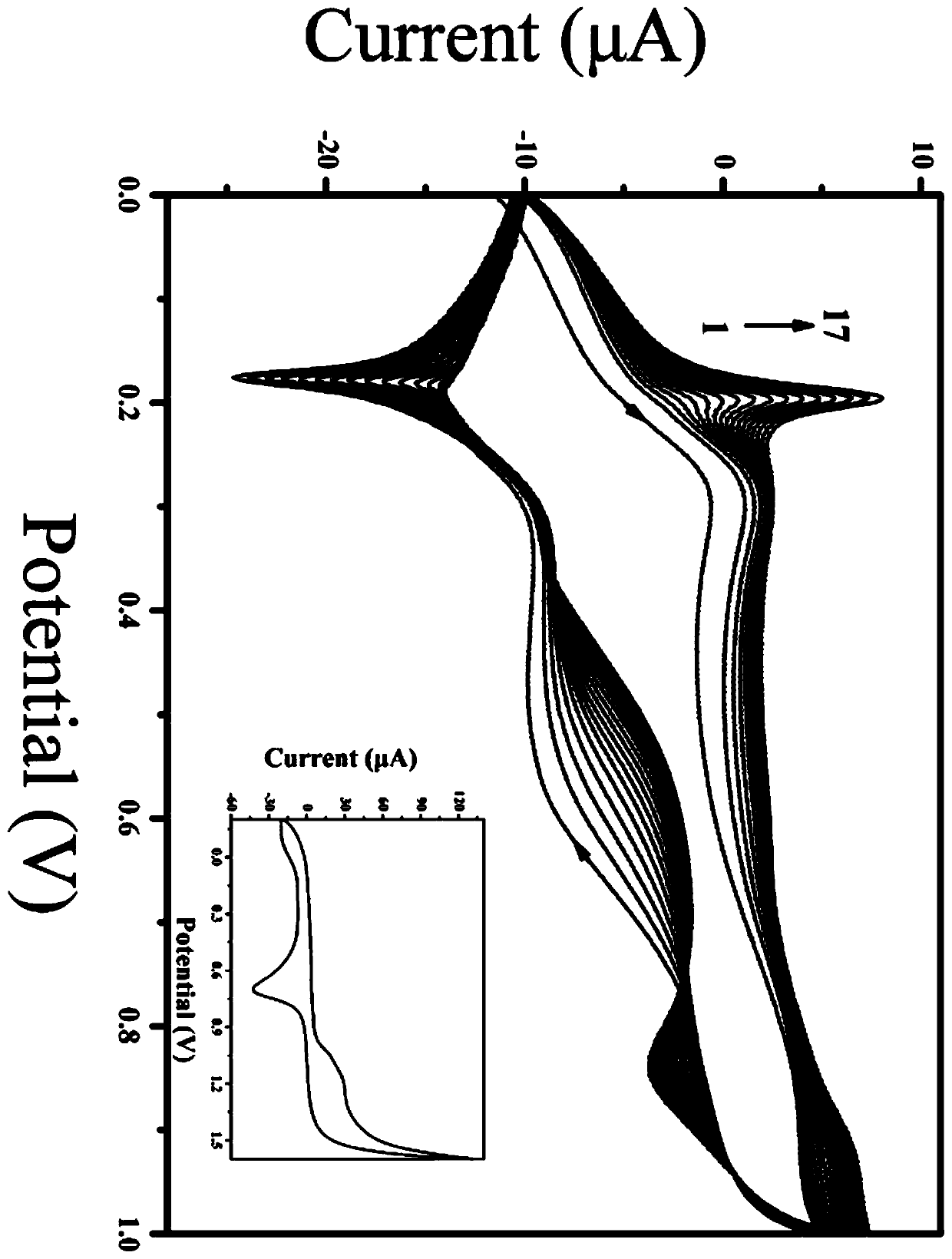

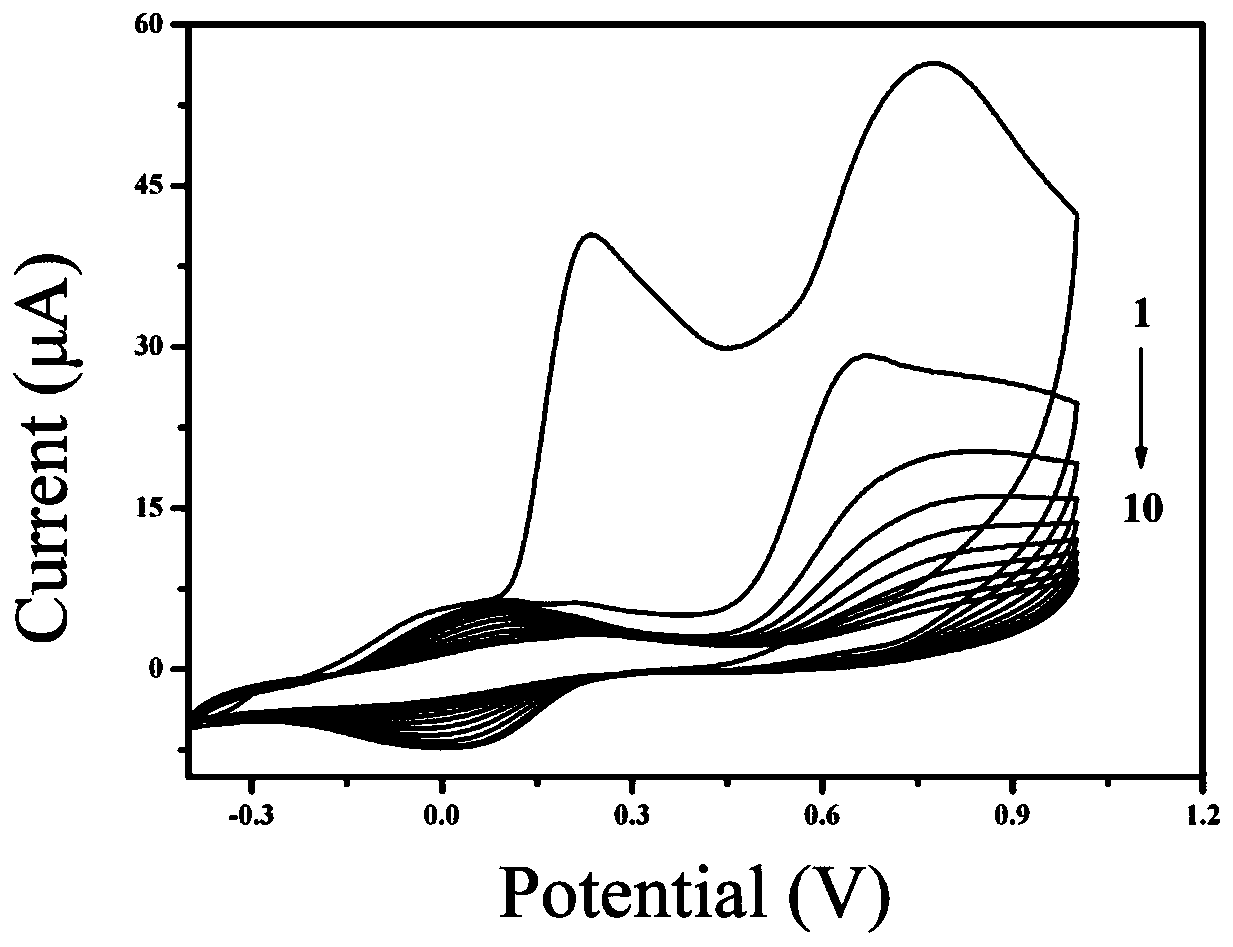

[0111] The mercaptographene-gold nanoparticle modified electrode was placed in the mixed solution, and gold-Prussian blue was deposited by cyclic voltammetry under the conditions of potential range 0-1.0V, scanning rate 50mV / s, and scanning 15 circles to obtain gold- Prussian blue-mercaptographene-gold nanoparticles modified electrodes. The mixed solution is 0.05mol / L potassium nitrate, 0.5mmol / L tetrachloroalloy acid and 0.5mmol / L potassium ferrocyanide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com