Multi-stage permeability increasing method for coal body containing gas

A gas-fired coal and gas technology, applied in the field of anti-gas outburst safety management in coal mines, can solve problems such as insufficient reduction of coal elastic energy, limited extraction and extraction capabilities, and long time-consuming water injection, and achieve the goal of improving quality and utilization value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

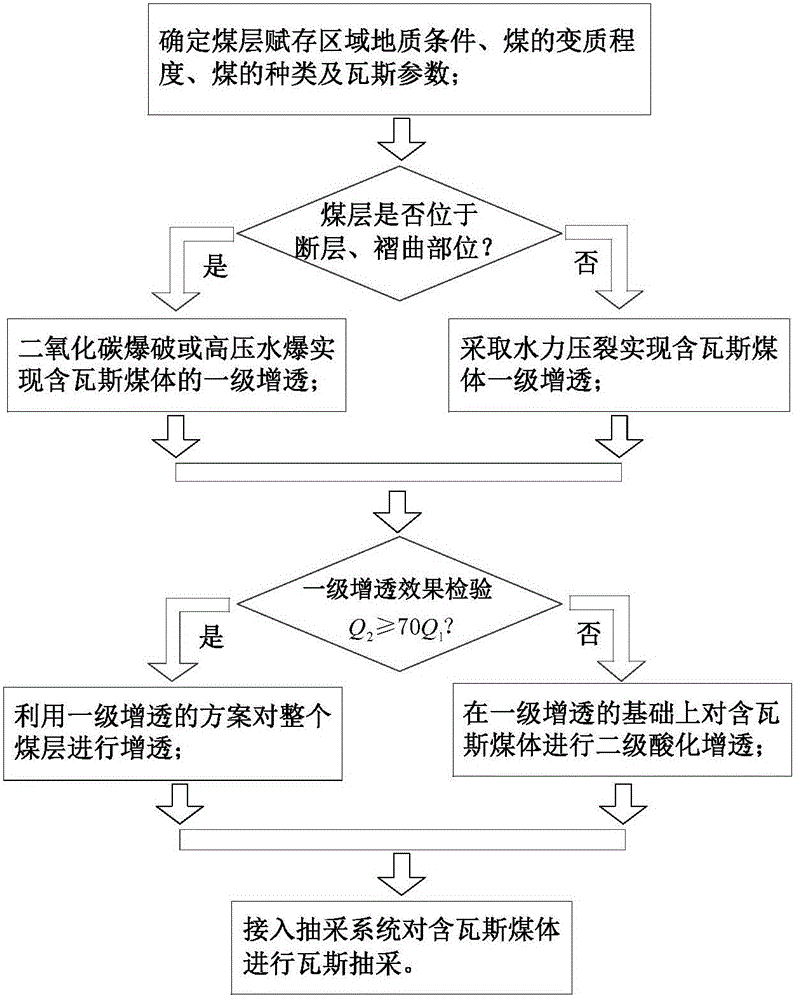

Method used

Image

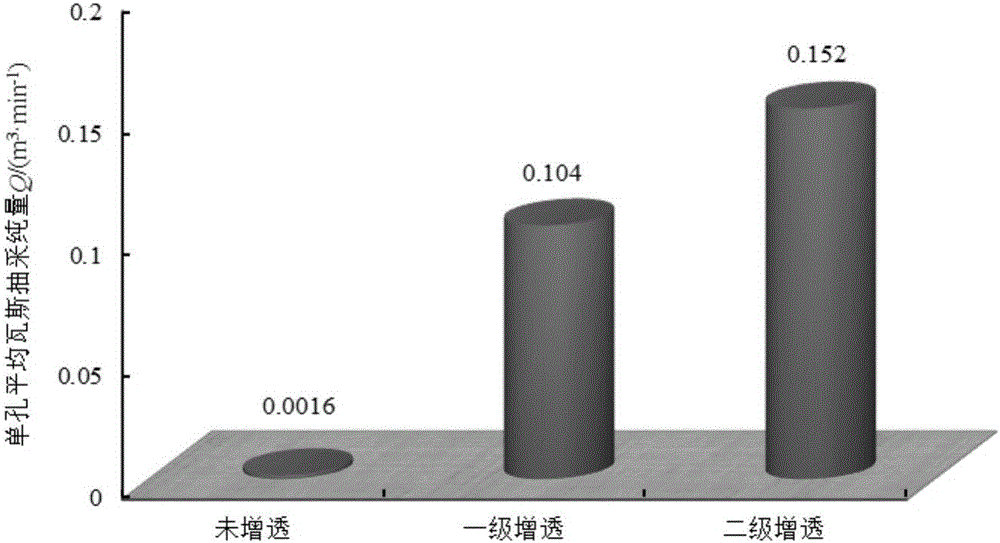

Examples

Embodiment Construction

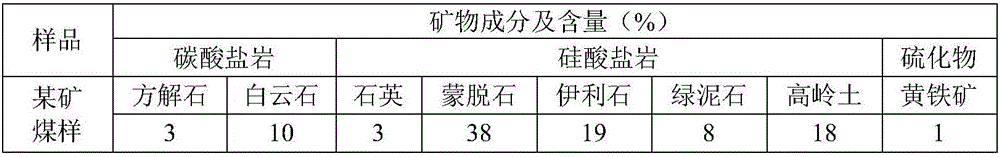

[0022] In order to fully demonstrate the features and advantages of the present invention, it will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0023] Research background: The 11105 working face of the C2 coal seam in a mine is mined by the strike longwall mining method. The dip length is 80m, the strike length is 600m, the thickness is 0.75-2.25m, the average thickness is 1.5m, and the coal seam dip angle is 2°. The coal seam structure is relatively simple, The stratum is relatively stable, there are no faults, folds and other structures nearby, and it can be mined in the area, which is a relatively stable coal seam. The average distance from the C3 coal seam is 17.35m, and the average distance from the C1 coal seam is 24.65m. The lithology of the roof is mudstone and sandy mudstone partially containing siltstone, and the lithology of the floor is mainly silty mudstone. The absolute gas pressure measured on site is up to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com