Ribbed rock wool cast-in-place concrete thermal insulation wall and construction method thereof

A technology for thermal insulation walls and concrete, applied in thermal insulation, wall, climate change adaptation and other directions, can solve problems such as low softness and strength, inability to use thermal insulation systems, etc., to achieve the effect of saving consumption, shortening construction period, and reliable structural connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

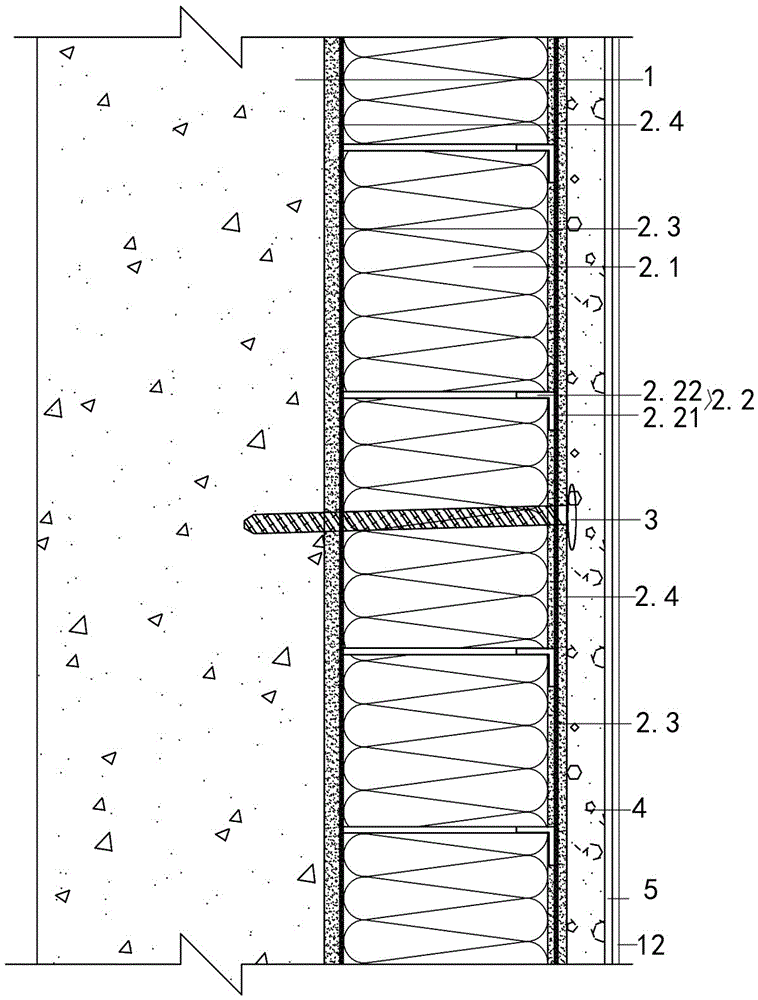

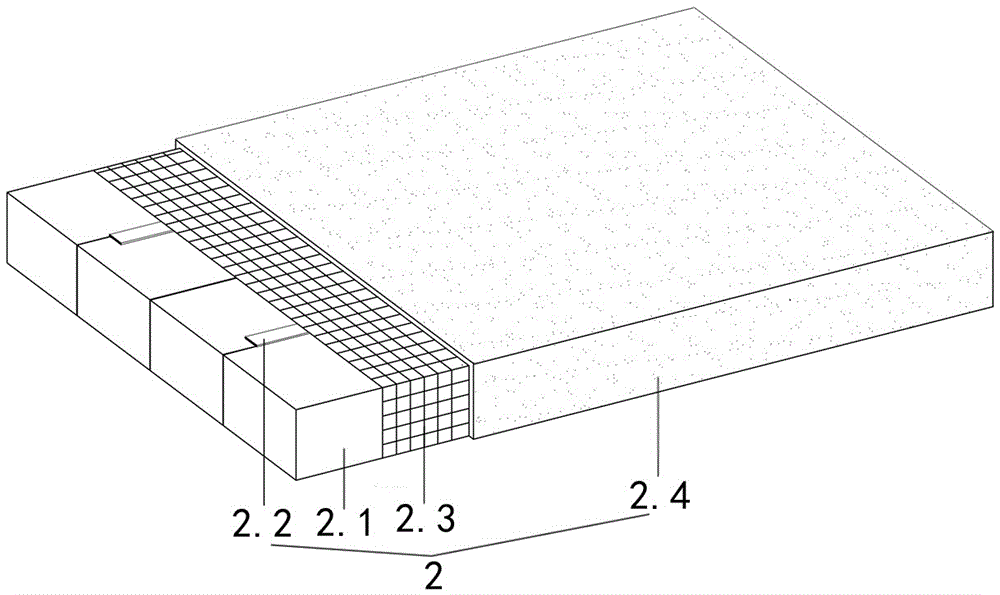

[0044] Examples see Figure 1-2 As shown, a ribbed rock wool cast-in-place concrete insulation wall comprises a wall base 1 of cast-in-situ reinforced concrete, a non-dismantling external formwork insulation board 2 fixedly connected to the outer surface of the wall base 1 of cast-in-situ reinforced concrete, The leveling layer 4 compounded on the outer surface of the non-removable external formwork insulation board 2, the anti-crack protective layer 5 compounded on the outer surface of the leveling layer 4, and the finish layer 12 compounded on the outer surface of the anti-crack protective layer 5, the demolition-free exterior The mold insulation board 2 is the outer formwork of the wall base 1 of cast-in-place reinforced concrete.

[0045] The non-removable external formwork insulation board 2 is a ribbed reinforced rock wool composite board, including a vertical thread rock wool core material 2.1 and a group of reinforcing ribs 2.2 arranged in parallel on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com