Construction technology of a kind of silt solidified soil

A construction technology and technology for solidifying soil, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as occupying large cultivated land and polluting the environment, and achieve the effect of facilitating soil excavation, good curing performance, and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

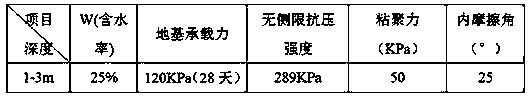

[0022] Langqi Hongguang Lake Park Silt Solidification Project

[0023] This project is located in Langqi Town, Fuzhou City, with a total curing volume of 260,000 cubic meters. The construction area for sludge solidification is as follows:

[0024] (1) The lakeside slope is solidified; (2) The retaining wall revetment is solidified;

[0025] (3) Solidification of the foundation in the filling area, including the solidification of the parking lot, the paved square and the foundation in the site;

[0026] (4) The subgrade of the garden road is solidified.

[0027] Construction steps:

[0028] (1) Clean the surface of the site before construction, remove the debris on the surface of the site, and level the construction area;

[0029] (2) Sludge sampling, testing and analysis: Sampling the sludge, analyzing the moisture content, particles and mineral components of the sludge, obtaining the analysis data of the sludge, and preparing a sludge curing agent according to the obtaine...

Embodiment 2

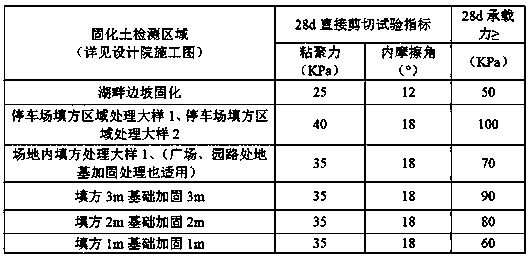

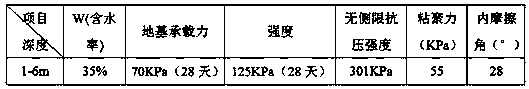

[0048] Soft foundation curing project in a container stacking area of a port in Shenzhen

[0049] This project is located in a port in Shenzhen, and the container area of the port is backfilled with dredging sludge. When backfilling to the design elevation, the shallow foundation shall be solidified. Its curing area is 200000m 2 , and its curing volume is 600,000 cubic meters. The object of solidification is highly compressible silt. The technical indicators of sludge are shown in the table below:

[0050]

[0051] Construction steps:

[0052] (1) Remove all accumulated water in ponds and ditches before construction, and excavate silt with organic matter content exceeding 6%;

[0053] (2) Sludge sampling, testing and analysis: Sampling the sludge, analyzing the moisture content, particles and mineral components of the sludge, obtaining the analysis data of the sludge, and preparing a sludge curing agent according to the obtained data; the sludge curing agent , its...

Embodiment 3

[0061] Dongdi Road (Haixu Road-Haiyue Road) road project of Tianjin Sino-Singapore Ecological City

[0062] Dongdi Road of this project is located in Tianjin Sino-Singapore Eco-City, the former Tianjin Binhai Tourist Area. The planning function is mainly based on landscape and tourism, supplemented by transportation. The site along Dongdi Road is a reclamation land reclamation area, and the vacuum reservation has not been made. The maximum thickness of the reclamation is 5m, and the reclamation period is 2 years. At the same time, there is about 6m of neritic sedimentary layer under the reclamation soil. The above-mentioned soil layer has a large natural void ratio, a high natural moisture content, and a large compressibility coefficient. They are all flow-plastic, and the foundation bearing capacity is low, which is a typical soft soil. Not only is it difficult for road construction machinery to enter the site, but also the post-construction settlement is relatively large.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com