Dry rubbing fastness improver for pigment printing fabric as well as preparation and using method of improver

A paint printing and fastness improvement technology, which is applied in the field of textile paint printing, can solve the problems of reduced dry rubbing fastness, easy-to-block mesh fabric feel, dry rubbing fastness index is difficult to meet the requirements of level 4, etc., to achieve preparation and use The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An agent for improving the dry rubbing fastness of pigment printed fabrics, comprising the following components by weight percentage: 50.0% of polyether-modified polydimethylsiloxane, 5.0% of blocked water-based polyurethane crosslinking agent, polyacrylate Thickener 1.0%, deionized water 44.0%;

[0022] Accurately weigh each component according to the above weight percentage, stir evenly, and prepare a dry rubbing fastness improving agent for pigment printed fabric, with a viscosity of 23400 mPa·s.

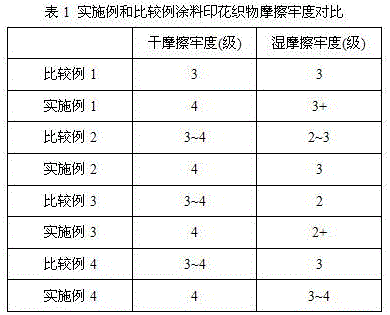

[0023] According to the formula of 5% paint red, 20% binder, 1.5% dry rubbing fastness enhancer of pigment printing fabric, and 3% thickener, the pigment printing paste is prepared, the viscosity is 25300 mPa s, and it is printed by rotary screen printing process Put it on pure cotton 40*40 fabric, dry it with hot air at 120°C, and then bake it at 160°C for 1.5 minutes to test its rubbing fastness, see Table 1.

Embodiment 2

[0027] An agent for improving the dry rubbing fastness of pigment printed fabrics, comprising the following components by weight percentage: 70.0% of hydroxyl-terminated polydimethylsiloxane, 7.0% of blocked water-based polyurethane crosslinking agent, polyacrylate extender Thickener 1.0%, deionized water 22.0%;

[0028] Accurately weigh each component according to the above weight percentage, stir evenly, and prepare a dry rubbing fastness improving agent for pigment printed fabric, with a viscosity of 25600 mPa·s.

[0029] According to the formula of 5% paint blue, 30% adhesive, 1.5% dry rubbing fastness enhancer of pigment printing fabric, and 3% thickener, the pigment printing paste is prepared, the viscosity is 26800 mPa s, and it is printed by rotary screen printing process Put it on pure cotton 40*40 fabric, dry it with hot air at 120°C, and then bake it at 160°C for 1.5 minutes to test its rubbing fastness, see Table 1.

Embodiment 3

[0033] An agent for improving the dry rubbing fastness of pigment printed fabrics, comprising the following components by weight percentage: 50.0% of polyether modified polyethylene wax emulsion, 5.0% of blocked water-based polyurethane crosslinking agent, and 1.5% of polyurethane thickener %, deionized water 45.0%;

[0034] Accurately weigh each component according to the above weight percentage, stir evenly, and prepare a dry rubbing fastness improving agent for pigment printing fabric, with a viscosity of 27200mPa·s.

[0035] According to the formula of 5% paint black, 25% binder, 1.0% pigment printing fabric dry rubbing fastness improving agent, 3% thickener, the pigment printing paste is prepared, the viscosity is 25700 mPa s, and it is printed by flat screen printing process Put it on pure cotton 15*15 fabric, dry it with hot air at 120°C, and then bake it at 160°C for 1.5 minutes to test its rubbing fastness, see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com