Sewing-free hot melt adhesive TPU leather and preparation method thereof

A hot-melt adhesive and sewing-free technology, which is applied in textiles and papermaking, can solve problems such as increased consumption costs, unsafe use, and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

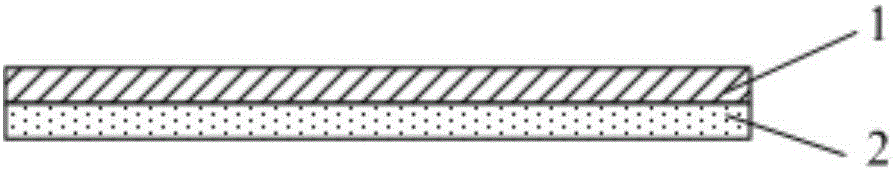

[0073] A kind of sewing-free hot-melt adhesive TPU leather, the said sewing-free hot-melt adhesive TPU leather comprises one layer of PU film, one layer of TPU hot-melt adhesive film and release paper or Release film, the TPU hot melt adhesive film is arranged on one side of the PU film; the thickness of the TPU hot melt adhesive film is 0.01mm; the thickness of the PU film is 0.01mm; the release paper or release The thickness of the film is 0.01mm;

[0074] The material of the release paper or release film is selected from any one or a combination of at least two of PVC, EVA, PP or PE;

[0075] Described TPU hot-melt adhesive film comprises following raw material component by weight part:

[0076] 30 parts of polyester polyols; 35 parts of polyether polyols; 20 parts of diisocyanates; 0.5 parts of catalysts; 0.5 parts of chain extenders; The hydroxyl-terminated polyester diol with a weight-average molecular weight of 500-800 obtained by polycondensation reaction at ~200°C; ...

Embodiment 1

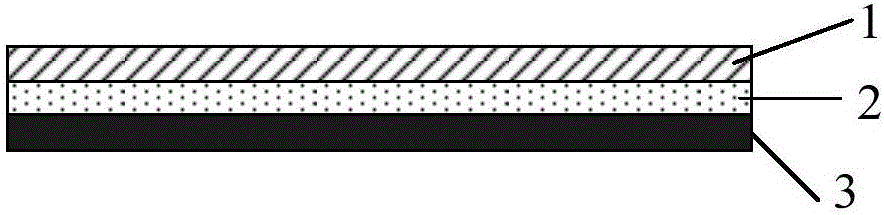

[0085] A kind of sewing-free hot-melt adhesive TPU leather, the said sewing-free hot-melt adhesive TPU leather comprises one layer of PU film, one layer of TPU hot-melt adhesive film and release paper or Release film, the TPU hot melt adhesive film is arranged on one side of the PU film; the thickness of the TPU hot melt adhesive film is 0.3mm; the thickness of the PU film is 3.0mm; the release paper or release The thickness of the film is 1.0mm;

[0086] The material of the release paper or release film is selected from any one or a combination of at least two of PVC, EVA, PP or PE;

[0087] Described TPU hot-melt adhesive film comprises following raw material component by weight part:

[0088] 40 parts of polyester polyol; 45 parts of polyether polyol; 50 parts of diisocyanate; 2 parts of catalyst; 10 parts of chain extender; 1 part of antioxidant; 4 parts of flame retardant; 4 parts of toughening agent; The polyol is a hydroxyl-terminated polyester diol with a weight-aver...

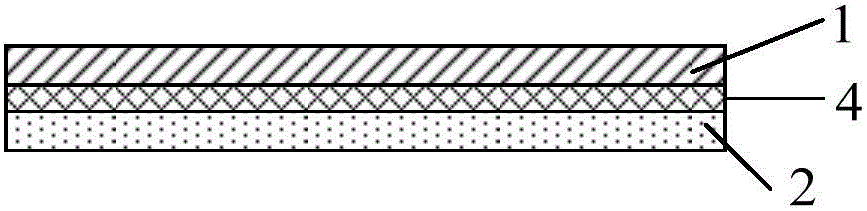

Embodiment 1

[0099] A kind of sewing-free hot-melt adhesive TPU leather, the said sewing-free hot-melt adhesive TPU leather comprises one layer of PU film, one layer of TPU hot-melt adhesive film and release paper or Release film, the TPU hot melt adhesive film is arranged on one side of the PU film; the thickness of the TPU hot melt adhesive film is 0.2mm; the thickness of the PU film is 1.0mm; the release paper or release The thickness of the film is 0.5mm;

[0100] The material of the release paper or release film is selected from any one or a combination of at least two of PVC, EVA, PP or PE;

[0101] Described TPU hot-melt adhesive film comprises following raw material component by weight part:

[0102] 32 parts of polyester polyol; 38 parts of polyether polyol; 20-50 parts of diisocyanate; 1 part of catalyst; 2 parts of chain extender; 0.5 part of antioxidant; 2 parts of flame retardant; 1.5 parts of toughening agent; The polyester polyol is a hydroxyl-terminated polyester diol wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com