A method for making a two-color color-changing three-layer mesh cloth

A technology of three-layer mesh fabric and production method, which is applied in the directions of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc. problem, to achieve the effect of good stability, obvious two-color effect, and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the two-color color-changing three-layer mesh cloth provided in this embodiment comprises the following steps:

[0040] S1: Yarn threading, select a double-needle bed warp knitting machine with more than six bars arranged in sequence, wherein the six adjacent bars are GB2, GB3, GB4, GB5, GB6 and GB7. What select for use in the present embodiment is the double-needle bed warp knitting machine with seven bar, wherein the first bar is GB1, and this bar is vacant, promptly does not wear yarn.

[0041]GB2, GB3, GB6 and GB7 all use semi-glossy polyester filament yarn for threading, the linear density of semi-gloss polyester filament yarn is preferably 75D, and the specifications of the semi-gloss polyester filament yarn used in this embodiment are full gloss and full drawing Stretch polyester yarn P-FDY75D / 36F (83dTEX / 36F); GB4 adopts cotton fiber high elastic yarn to carry out threading, and the linear density of cotton fiber high elastic yarn is pr...

Embodiment 2

[0053] Compared with Embodiment 1, this embodiment has the following differences (i.e. except the following points, the preparation method provided by this embodiment is the same as Embodiment 1):

[0054] First of all, the threading methods of GB2 to GB7 are different. In this embodiment, each pan head of GB2 and GB3 wears 298 yarns respectively, and each pan head of GB4 and GB5 wears 238 yarns respectively. Each pan head of GB6 and GB7 is respectively worn with 476 yarns. In addition, both GB2 and GB3 are threaded in the way of three threads, one empty, one thread, one empty, one threaded and one empty, GB4 and GB5 are threaded in the way of one thread and one empty, and GB6 and GB7 are threaded in the way of full thread.

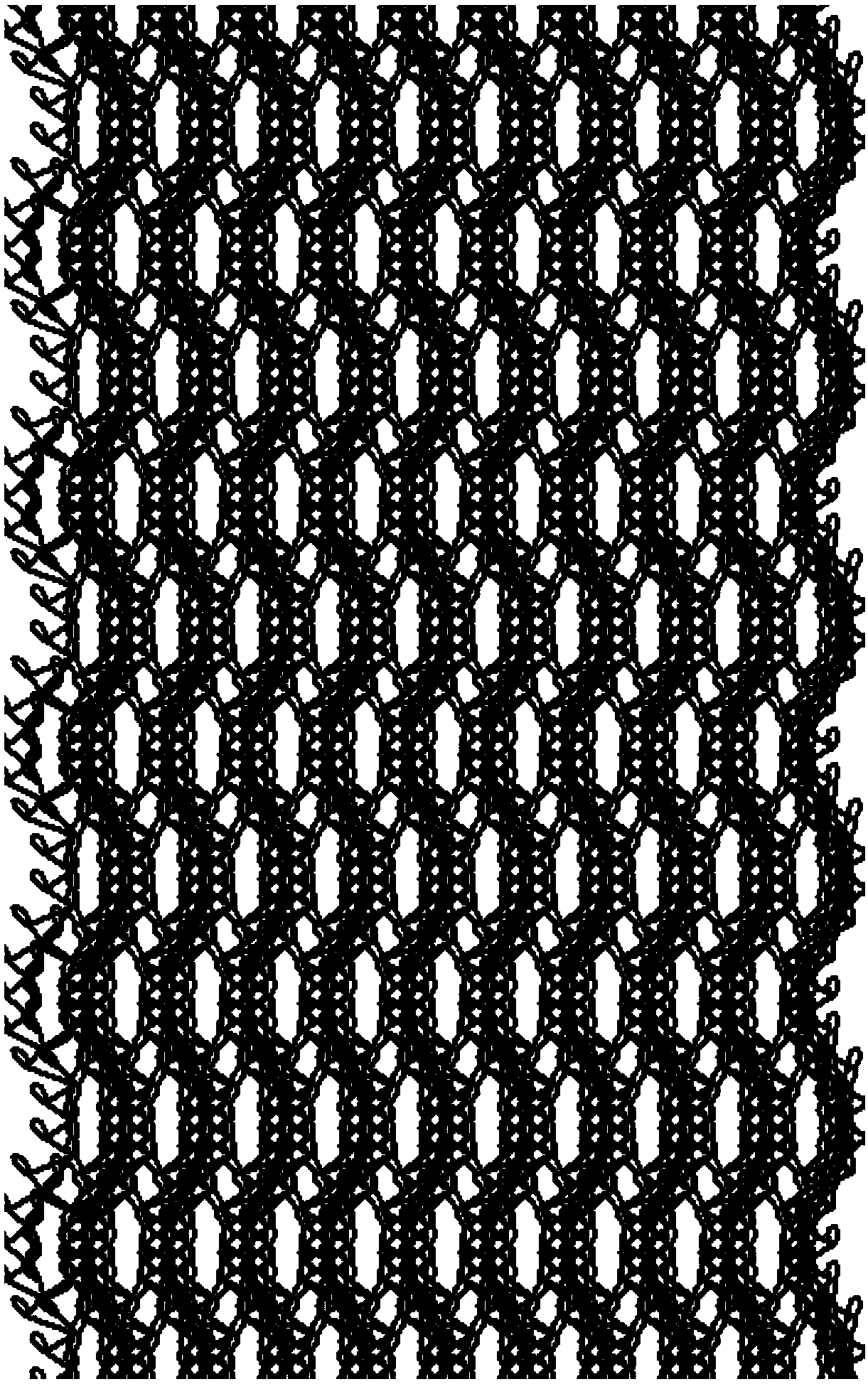

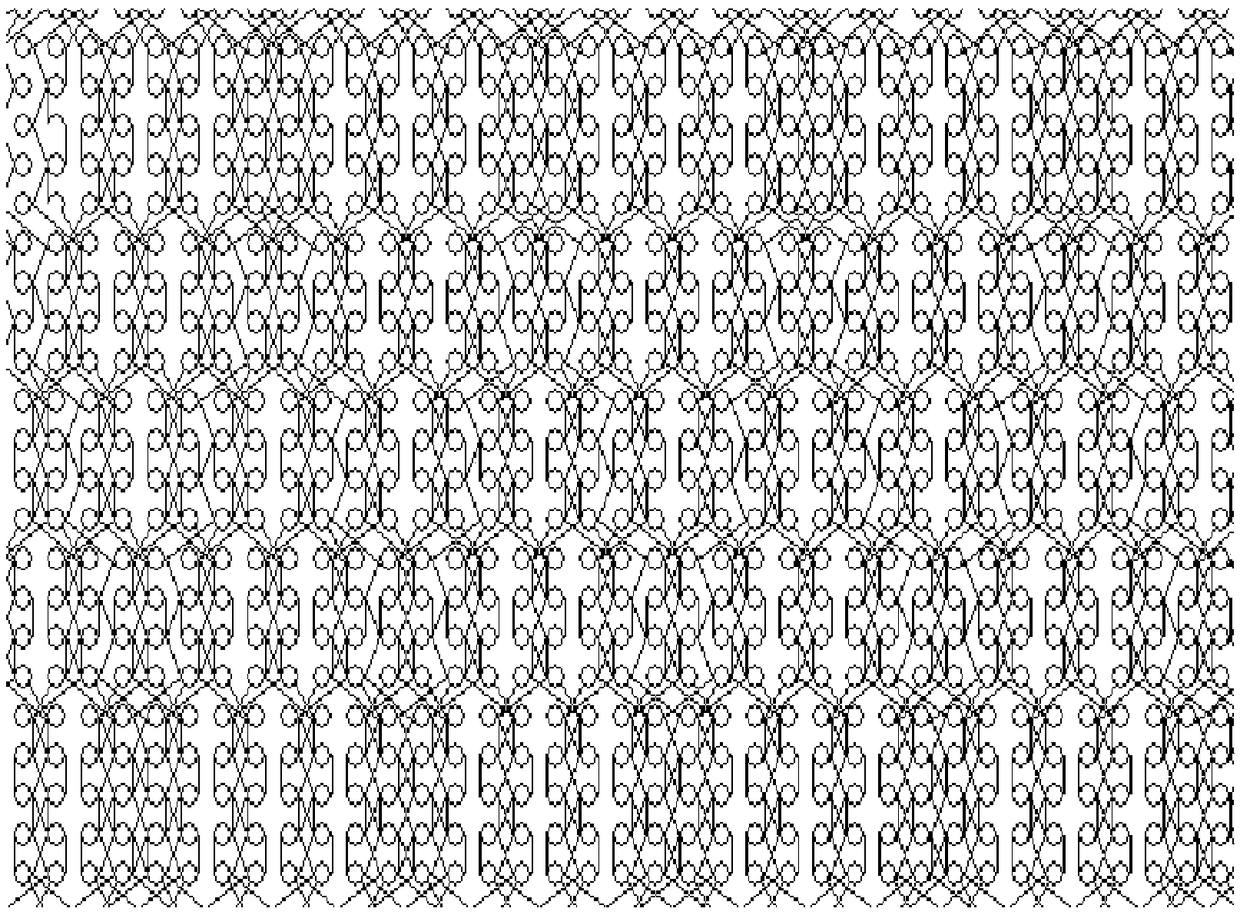

[0055] The second is the difference in weaving methods between the surface layer and the middle layer. In this embodiment, GB2 and GB3 weave to form such figure 2 In the surface layer shown, the let-off amount of GB2 is 1770mm / lack, and the yarn pad mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com