Filter screen

A filter screen and filter frame technology, applied in the filter screen field, can solve problems such as poor capacity, loss of effective adsorption capacity, deformation, etc., and achieve large filter area, long service life and good filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

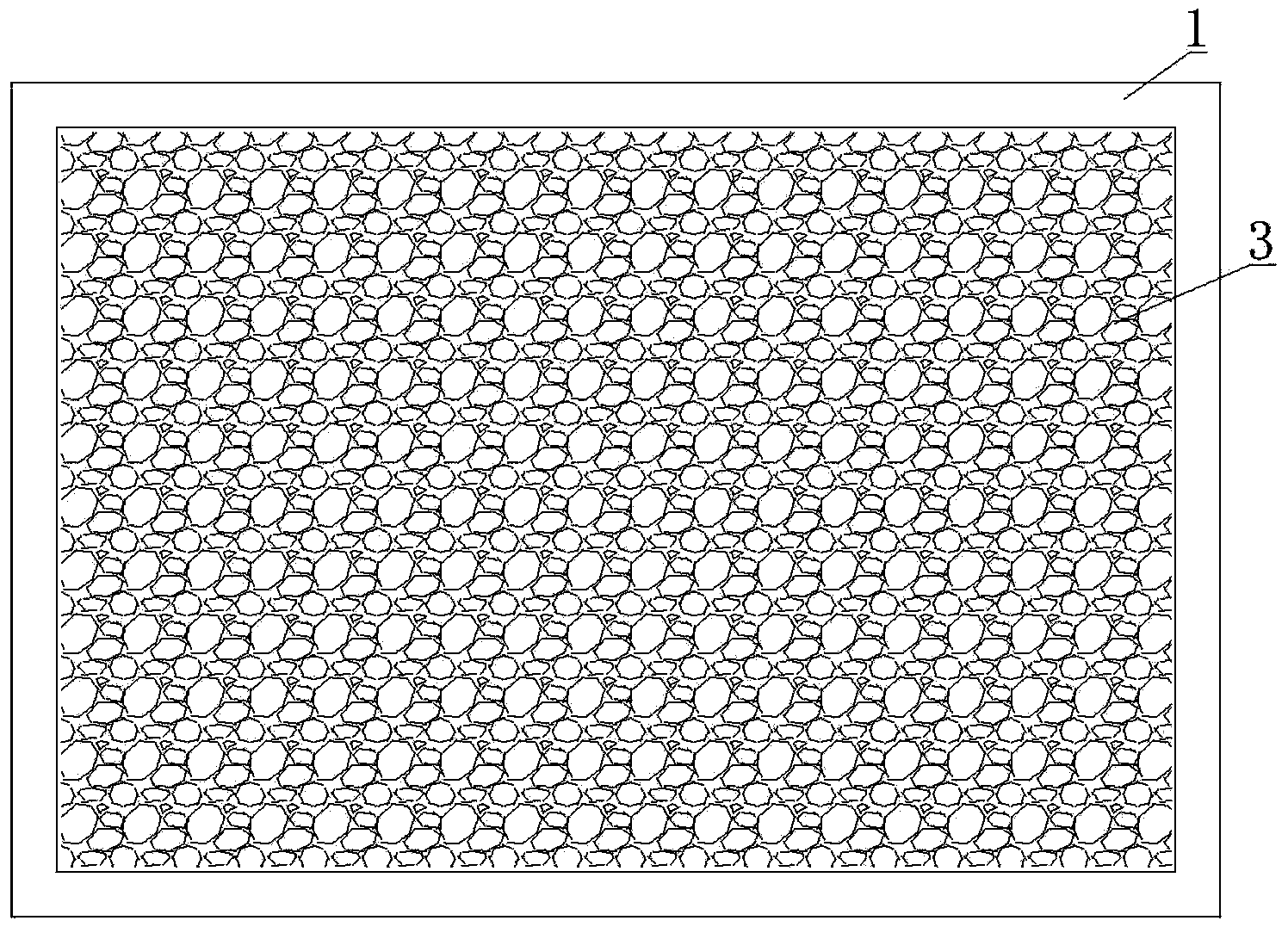

[0032] Such as figure 1 As shown, a filter screen includes a filter screen frame 1 and a filter material 3 arranged in the filter screen frame 1, and the filter material 3 is a polyurethane synthetic resin filter material. The polyurethane synthetic resin filter material is foamed into a spongy filter material with pores, and the spongy filter material is arranged in the filter screen frame 1 .

[0033] The polyurethane synthetic resin filter material is directly arranged in the filter screen frame 1 to effectively filter dust, germs and even mosquitoes in the air. The polyurethane synthetic resin filter material has a large filter area and is viscous at the same time. The air passing through the filter can be fully filtered without affecting the air permeability; when dust, germs and even mosquitoes in the air pass through the filter, it will Adhering to the surface of polyurethane synthetic resin filter material, the filtering effect is good; polyurethane synthetic resin fi...

Embodiment 2

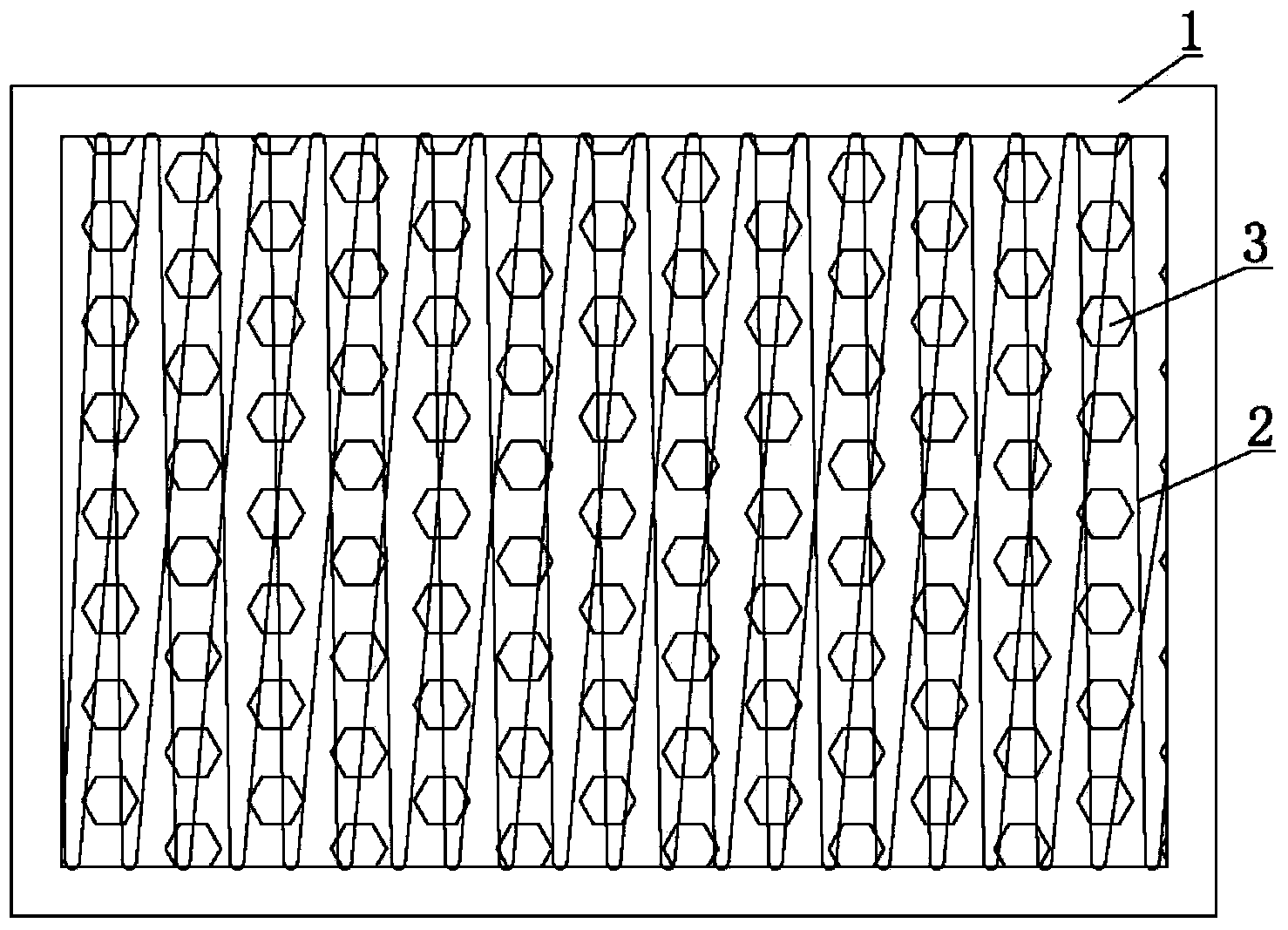

[0036] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that it also includes a support body 2 connected to the screen frame 1, and the polyurethane synthetic resin filter material is adhered to the support body 2.

[0037]The support body 2 is a linear body or a filament 22 . The diameter of the linear body or filamentary body 22 is 0.01 mm to 1 mm. The two ends of linear body or filamentary body 22 are connected to filter screen frame 11, and linear body or filamentary body 22 can be arranged in parallel, or staggered arrangement, are arranged closely in the filter screen frame 11, effectively filter the dust in the air, Germs and even mosquitoes. The diameter of the linear body or the filament 22 is 0.01 mm to 1 mm, specifically, the diameter can be set to 0.01 mm, 0.02 mm, 0.03 mm, 0.05 mm, 0.08 mm, 0.09 mm, 0.1 mm, 0.2 mm, 0.3 mm, 0.5 mm mm, 0.8mm, 1.0mm, etc., use the linear body or filament 22 with the above-mentioned diameter, s...

Embodiment 3

[0040] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that the support body 2 includes several linear bodies or several filamentary bodies 22, and several support rods 21, and the several support rods 21 are vertically arranged on the screen frame In the plane formed by 11 , the linear body or filament 22 is wound around different support rods 21 , and the polyurethane synthetic resin filter material is arranged on the linear body or filament 22 .

[0041] Such as Figure 4 As shown, the linear bodies or filaments 22 are alternately wound around different support rods 21 to form a filter screen core layer, and the filter screen core layer is more than two layers. The linear body or filament 22 is wound irregularly or regularly on the support rod 21 to form a filter core layer, and then a second layer of filter core is formed on the first layer of filter core layer with its mesh staggered After several times in this way, a three-dimensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com