Preparation method for oversized multilayer single crystal graphene and large-size single crystal copper nickel alloy

A single-crystal graphene, super-sized technology, applied in chemical instruments and methods, single-crystal growth, single-crystal growth and other directions, can solve the problem that affects the intrinsic properties of graphene, the progress of graphene industrialization is not smooth, and the application of graphene is limited. and other problems, to achieve the effect of good application prospect, low cost and few defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

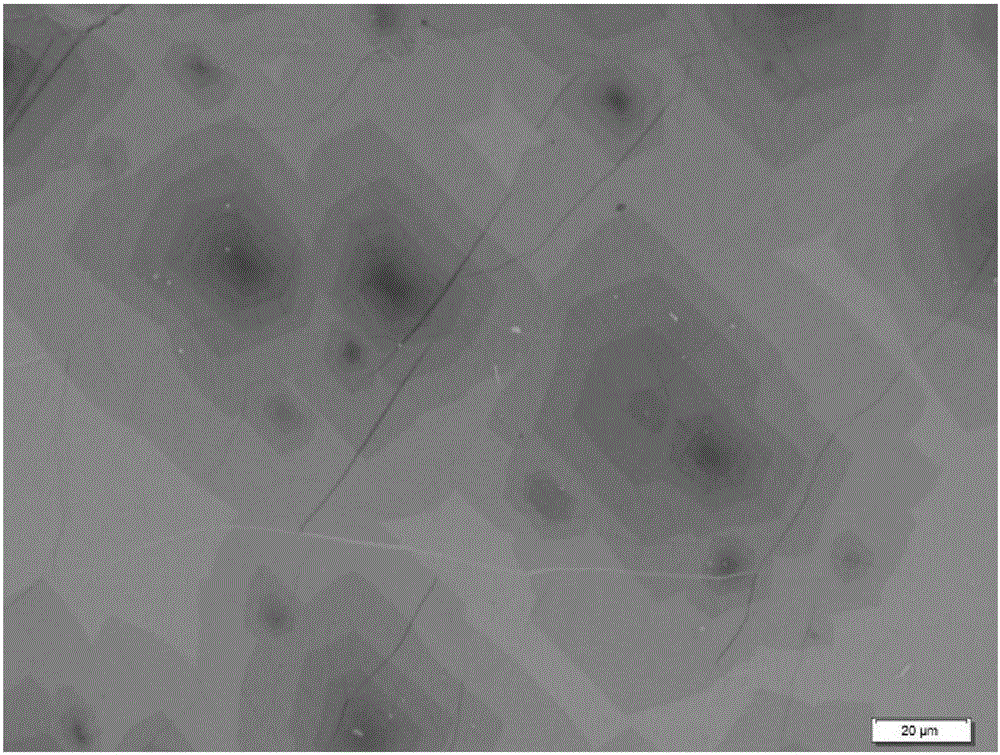

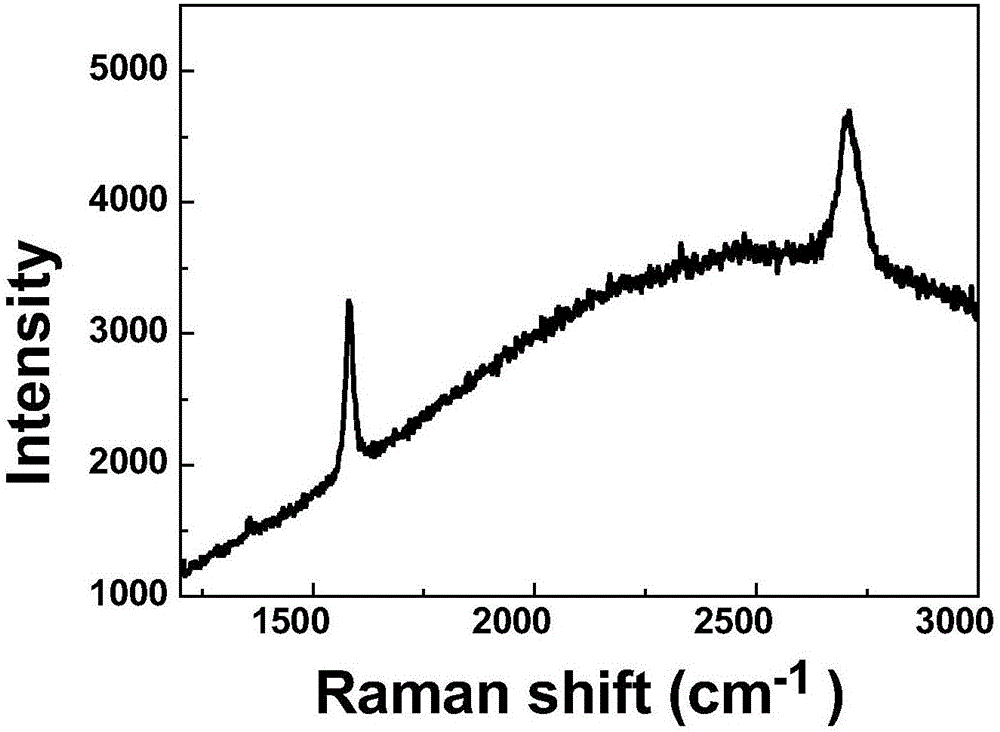

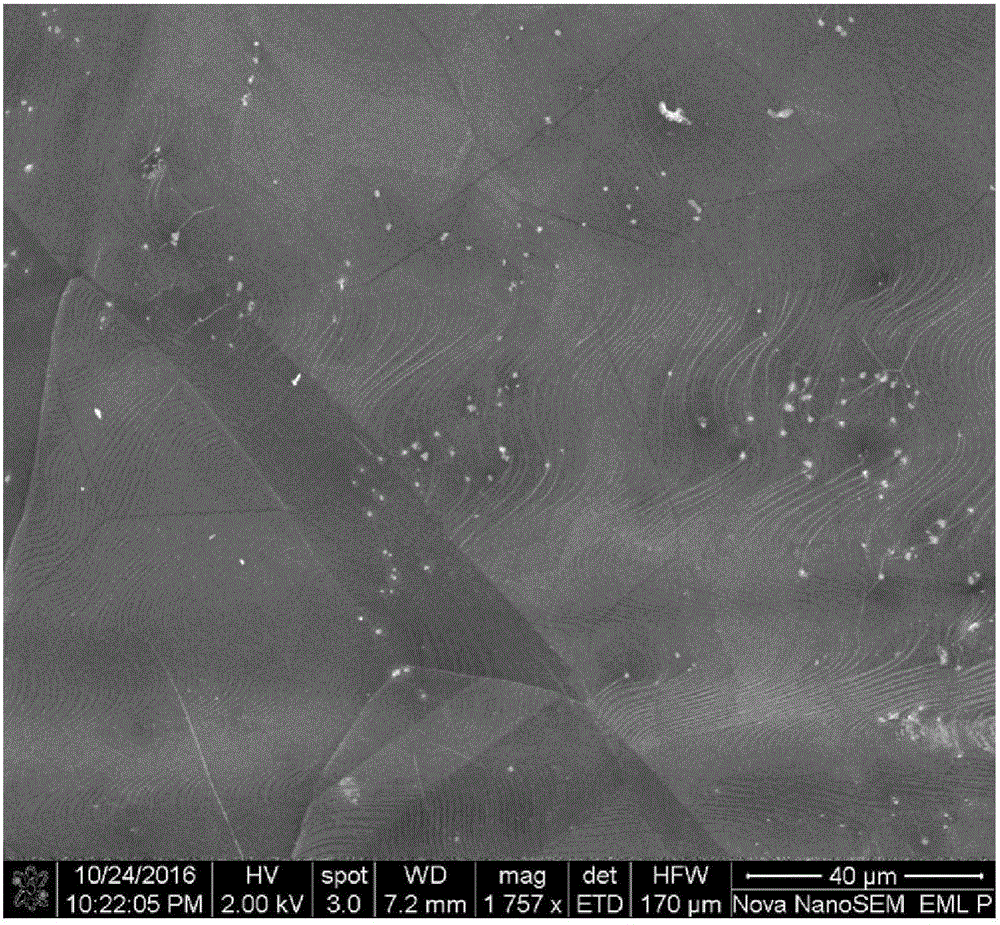

[0016] Embodiment 1: A method for annealing nickel-plated single-crystal copper foil to prepare single-crystal copper-nickel alloy and super-large-scale multilayer single-crystal graphene

[0017] 1. Place the nickel-plated single crystal copper foil flat on the high temperature resistant substrate, put it into the chemical vapor deposition equipment, pass inert gas with a flow rate of 300 sccm or more, and pass in H 2 Gas, H 2 The flow rate is 2 to 500 sccm, and the working pressure is normal pressure (that is, one atmospheric pressure or about 1×10 5 Pa), and then start to heat up, and the heating process lasts for 50 to 70 minutes; wherein, the high temperature resistant substrate includes quartz, fused silica, Al 2 o 3 , ZrO and MgO;

[0018] 2. When the temperature rises to 800-1100°C, the flow rate of the inert gas remains unchanged, and the annealing process is carried out, and the annealing duration is 30min-10h;

[0019] 3. After the annealing is over, start to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com