Method for alpha-ketoglutarate production by catalysis of L-glutamate dehydrogenase

A technology of glutamic acid dehydrogenase and ketoglutarate, which is applied in the field of biochemistry, can solve the problems of high cost, heavy pollution, complicated steps and the like, and achieves the effects of low production cost, good reaction selectivity and low raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

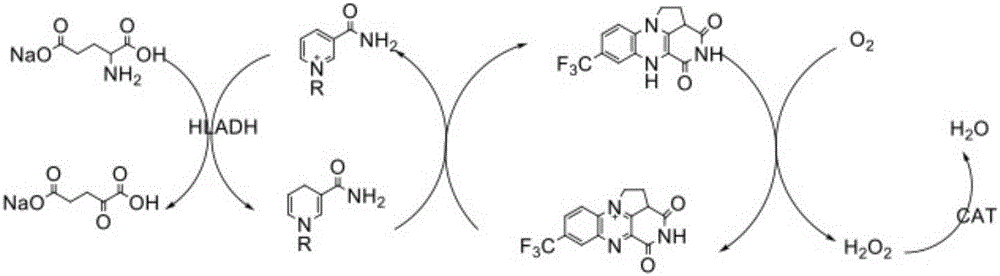

Image

Examples

Embodiment 1

[0035] Example 1: L-glutamate dehydrogenase catalyzes the production of α-ketoglutarate at different NAD+ concentrations

[0036] At 30°C, in 10ml pH8 Tris-HCl reaction system, L-glutamic acid 15mM, NAD+, 7-trifluoromethyl-1,10-ethyleneisoalloxazine chloride 1mM, catalase 500U / mL, L-glutamate dehydrogenase 5U / mL, the reaction solution was connected to the outside air. Take 200 μL of the reaction solution after reacting for 48 hours, add 800 μL of water to dilute, and detect the reaction progress by liquid phase. The results are shown in Table 1.

[0037] Table 1

[0038] NAD+concentration(mM) Yield(%) 0.5 52.1 1 90.7 1.5 75.2 2 50.5 2.5 46.8 3 43.7

Embodiment 2

[0039] Example 2: L-glutamate dehydrogenase catalyzes the production of α-ketoglutarate at different concentrations of 7-trifluoromethyl-1,10-ethyleneisoalloxazine chloride

[0040] At 30°C, in 10ml pH8 Tris-HCl reaction system, L-glutamic acid 15mM, NAD+1mM, 7-trifluoromethyl-1,10-ethyleneisoalloxazine chloride, catalase 500U / mL, L-glutamate dehydrogenase 5U / mL, the reaction solution is connected with the outside air. Take 200 μL of the 48-h reaction solution, add 800 μL of water to dilute, and detect the reaction progress by liquid phase. The results are shown in Table 2.

[0041] Table 2

[0042] 7-Trifluoromethyl-1,10-ethyleneisoalloxazine chloride (mM) Yield(%) 0.5 47.6 1 90.7 1.5 72.7 2 63.7 2.5 58.2 3 54.1

Embodiment 3

[0043] Example 3: L-glutamate dehydrogenase catalyzes the production of α-ketoglutarate under different pH types

[0044]At 30°C, in 10ml of pH8 different buffer systems, L-glutamic acid 15mM, NAD+1mM, 7-trifluoromethyl-1,10-ethyleneisoalloxazine chloride 1mM, catalase 500U / mL, L-glutamate dehydrogenase 5U / mL, the reaction solution is connected with the outside air. Take 200 μL of the reaction solution after reacting for 48 hours, add 800 μL of water to dilute, and detect the reaction progress by liquid phase. The results are shown in Table 3.

[0045] table 3

[0046] pH type Yield(%) Tris-HCl 90.7 KPi 50.4 CBS 60.2 CPBS 71.8 barbiturate - hydrochloric acid 53.6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com