A device and method for removing tar from biomass gasification based on chemical looping reforming

A biomass and chemical chain technology, used in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of easy carbon deposition, pre-reduction and regeneration difficulties, and achieve regeneration and elimination of carbon deposition. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

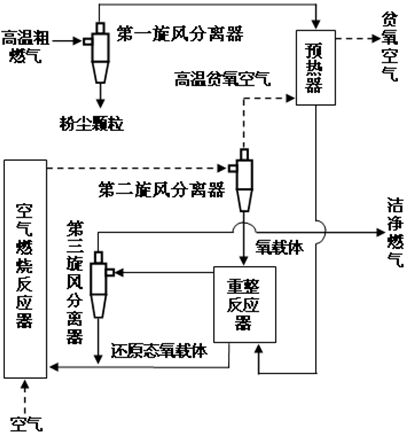

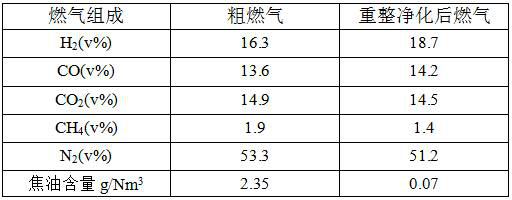

[0043] Taking the removal of crude gas tar from biomass downdraft fixed bed air gasification as an example.

[0044] Raw gas from biomass downdraft fixed bed gasification 10.0 Nm 3 / h, the tar content is 2.35g / Nm 3 , the temperature is 450°C, after being separated and dedusted by the first cyclone separator and preheated by the preheater, it enters the reforming reactor and the high-temperature oxygen carrier (CuO-NiO / Al 2 o 3 , 6kg / h) reaction, the oxygen carrier is reduced, and the tar macromolecules in the raw gas are partially oxidized and catalytically reformed into CO and H 2 The tar content of the gas obtained after separation and dust removal by the third cyclone separator is 0.07g / Nm 3 , the removal rate of tar in crude gas is 97%;

[0045] The reduced oxygen carrier (there may be carbon deposits on the surface) enters the air combustion reactor, and the air excess coefficient controlling the combustion reaction of the oxygen carrier is 0.95. The reduced oxygen ca...

Embodiment 2

[0051] This method is used as an example to illustrate the removal of crude gas tar from biomass downdraft fixed bed oxygen-enriched (50v% oxygen) gasification.

[0052] Raw gas from biomass fixed bed oxygen-enriched (50v% oxygen) gasification 10.0 Nm 3 / h, the tar content is 1.02g / Nm 3 , with a temperature of 480°C. After being separated and dedusted by the first cyclone separator and preheated by the preheater, it enters the reforming reactor and the high-temperature oxygen carrier (Mn 2 o 3 -NiO / Al 2 o 3 , 5kg / h) reaction, the oxygen carrier is reduced, and the tar macromolecules in the raw gas are partially oxidized and catalytically reformed into CO and H 2 Transformation and removal of small molecular substances, the tar content of the gas obtained after passing through the third cyclone separator is 0.05g / Nm 3 , the removal rate of tar in crude gas is 95%;

[0053] The reduced oxygen carrier (there may be carbon deposits on the surface) enters the air combustion r...

Embodiment 3

[0059] This method is used as an example to illustrate the removal of crude gas tar from biomass fluidized bed air gasification.

[0060] Raw gas from biomass fluidized bed gasification 5.0 Nm 3 / h, the tar content is 11.72g / Nm 3 , with a temperature of 520°C. After being separated and dedusted by the first cyclone separator and preheated by the preheater, it enters the reforming reactor and the high-temperature oxygen carrier (Fe 2 o 3 -NiO / Al 2 o 3 , 5.4kg / h) reaction, the oxygen carrier is reduced, and the tar macromolecules in the raw gas are partially oxidized and catalytically reformed into CO and H 2 After the third cyclone separator separates and removes dust, the tar content of the gas obtained is 0.92g / Nm 3 , the removal rate of tar in crude gas is 92%;

[0061] The reduced oxygen carrier (there may be carbon deposits on the surface) enters the air combustion reactor, and the air excess coefficient controlling the combustion reaction of the oxygen carrier is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com