Ultralow-density oil-base drilling fluid and preparation method thereof

An oil-based drilling fluid, ultra-low density technology, applied in the field of oil-based drilling fluid, can solve the problems of poor stability, difficult to adapt to long-term drilling, completion requirements, difficult to prepare, etc., to prevent agglomeration, good emulsion stability, The effect of low temperature and high pressure filter loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

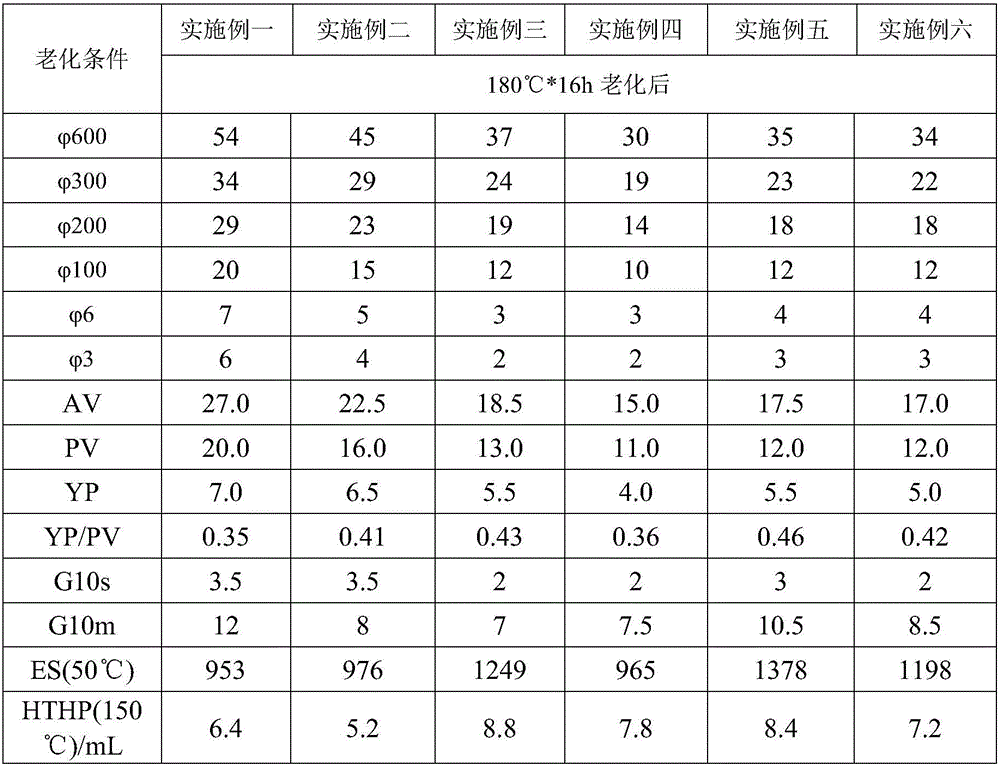

Examples

Embodiment 1

[0045]An ultra-low-density oil-based drilling fluid prepared from the following raw material components by weight and percentage:

[0046] Base oil 95.00%; Density reducer 0.00%; Suspension stabilizer 0.00%; Emulsifier 2.00%; Calcium chloride aqueous solution 2.00%; Among them, the base oil is mixed with 3# white oil, 5# white oil, and natural gas oil, and then add a flash point enhancer in the stirring state, and let stand for 1h; stir at a low speed at a temperature of 30°C, Use a mixing funnel for vacuum suction, slowly add oil-soluble gas-phase nano-silica, and add while stirring. The dosage ratio of the silicon and the flash point enhancer is 30:10:60:5:2; wherein, the flash point enhancer is menthol. The emulsifier is long-chain alkyl fatty acid polyamide nonionic surfactant; the tackifier is polyamide resin; the fluid loss reducer is humic acid amide; the alkalinity regulator is magnesium oxide. The mass concentration of the calcium chloride aqueous solution is 20.00%...

Embodiment 2

[0049] An ultra-low-density oil-based drilling fluid prepared from the following raw material components by weight and percentage:

[0050] Base oil 90.00%; Density reducer 0.00%; Suspension stabilizer 0.20%; Emulsifier 3.50%; Calcium chloride aqueous solution 5.00%; Among them, the base oil is mixed with 3# white oil, 5# white oil, and natural gas oil, and then add a flash point enhancer in the stirring state, and let stand for 1h; stir at a low speed at a temperature of 30°C, Use a mixing funnel for vacuum suction, slowly add oil-soluble gas-phase nano-silica, and add while stirring. The dosage ratio of silicon and the flash point raising agent is 40:15:50:10:4; wherein, the flash point raising agent is pinene. The emulsifier is long-chain alkyl quaternary ammonium salt cationic surfactant; the tackifier is organic montmorillonite; the fluid loss reducer is oil-soluble resin; the alkalinity regulator is calcium oxide. The mass concentration of the calcium chloride aqueous ...

Embodiment 3

[0053] An ultra-low-density oil-based drilling fluid prepared from the following raw material components by weight and percentage:

[0054] Base oil 90.00%; Density reducer 5.00%; Suspension stabilizer 0.20%; Emulsifier 3.00%; Calcium chloride aqueous solution 5.00%; Among them, the base oil is mixed with 3# white oil, 5# white oil, and natural gas oil, and then add a flash point enhancer in the stirring state, and let it stand for 0.5h; stir at a low speed at a temperature of 40°C , use a mixing funnel to carry out vacuum suction, slowly add oil-soluble gas-phase nano-silica, add while stirring, and the adding process is controlled within 2 hours, of which 3# white oil, 5# white oil, natural gas to oil, oil-soluble gas-phase nano-silica The dosage ratio of silicon oxide and the flash point enhancer is 35:20:60:6:3; wherein, the flash point enhancer is citral. The density reducer is made by mixing hollow glass microspheres, nano-alumina, and nano-calcium carbonate in a ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com