Adhesive glue for in-mold decoration and preparation method thereof

A technology of in-mold decoration and adhesive glue, applied in the direction of adhesives, etc., can solve the problems of general adhesion and printability, limited use, etc., and achieve the effects of excellent adhesion, good high temperature and high humidity resistance, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

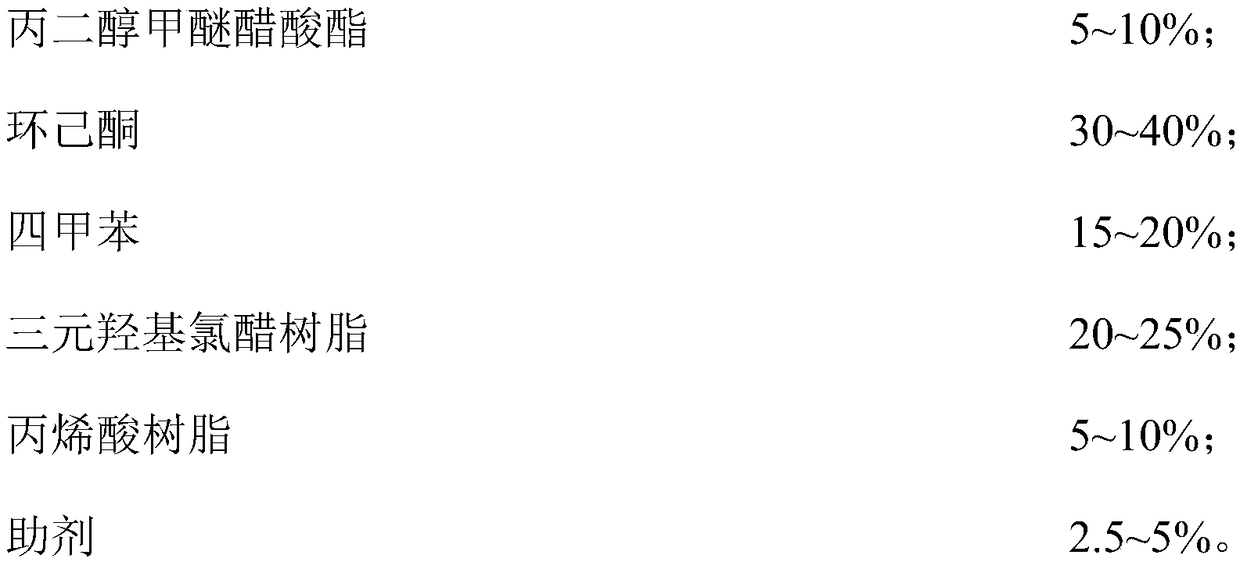

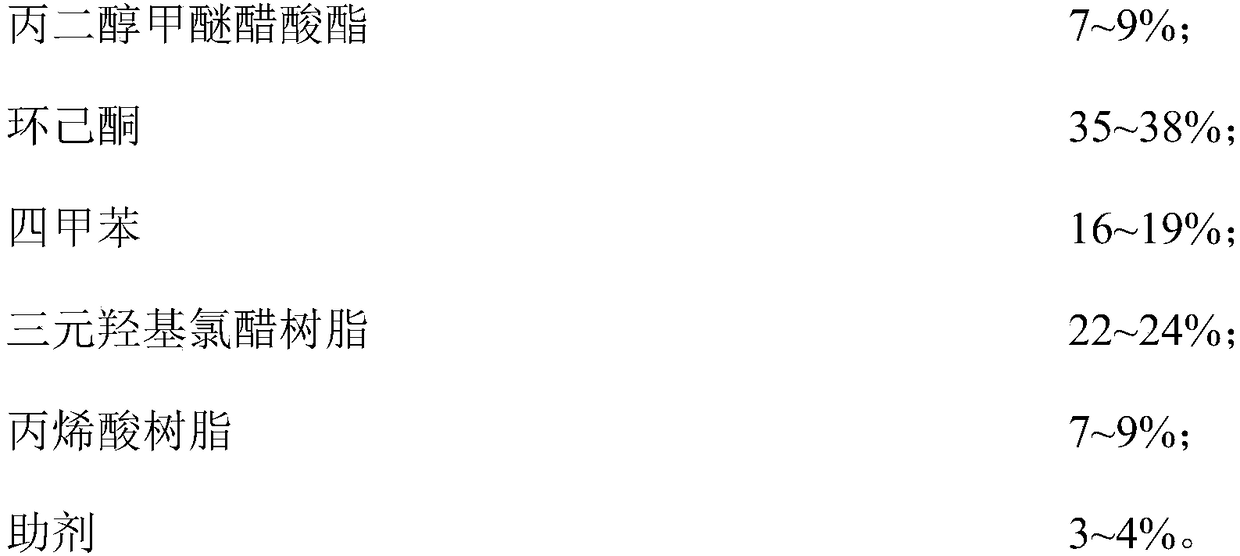

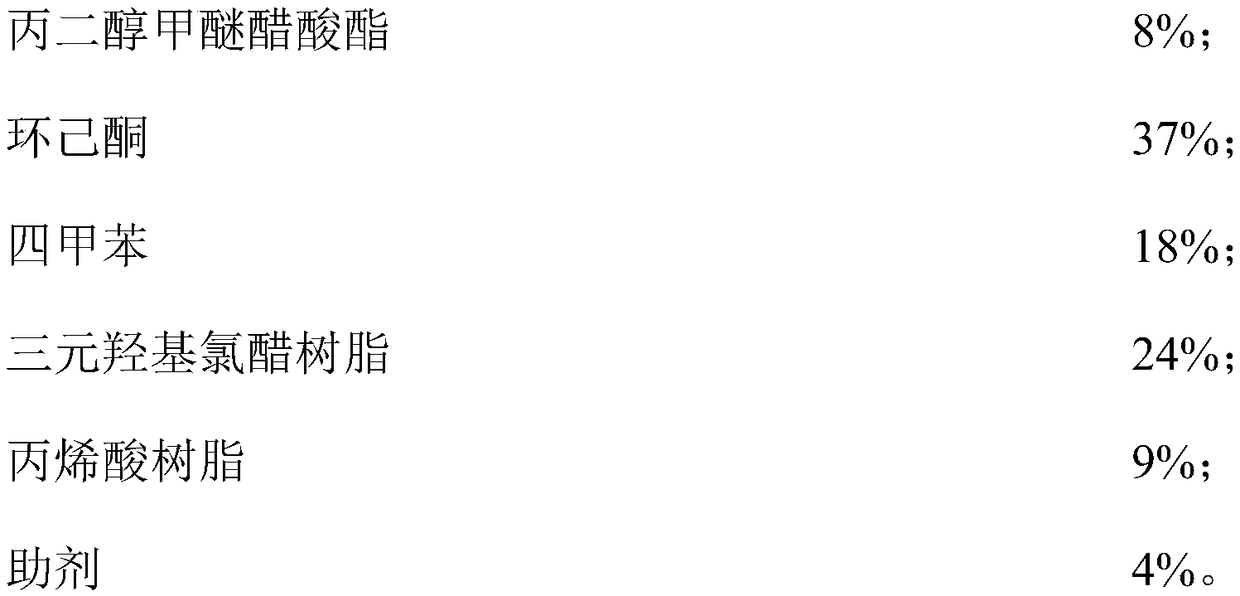

Method used

Image

Examples

preparation example Construction

[0043] The specific embodiment part of the present invention also provides a kind of preparation method of above-mentioned adhesive glue, and described method comprises the following steps:

[0044] (1) Propylene glycol methyl ether acetate, cyclohexanone, and tetramethylbenzene are mixed to obtain a mixed solvent, and tertiary hydroxyl chloride resin and acrylic resin are added in the mixed solvent to obtain a resin solution;

[0045] (2) adding fumed silica to the resin solution obtained in step (1), grinding and dispersing to obtain a semi-finished adhesive;

[0046] (3) Adding a defoamer to the adhesive semi-finished product obtained in step (2) to obtain an adhesive for in-mold decoration.

[0047] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as spe...

Embodiment 1

[0049] A preparation method of adhesive glue for in-mold decoration, said preparation method comprising the following steps:

[0050] (1) 5% propylene glycol methyl ether acetate, 40% cyclohexanone, and 20% tetramethylbenzene are mixed to obtain a mixed solvent, and 25% tertiary hydroxychloride resin and 5% acrylic acid are added to the mixed solvent under stirring at 800r / min Resin, continue to stir 2h, obtain resin solution;

[0051] (2) Add 4% fumed silica to the resin solution obtained in step (1) under stirring at 600r / min, continue stirring for 15min, grind and disperse, and obtain a semi-finished adhesive;

[0052] (3) Add 1% silicone defoamer to the adhesive semi-finished product obtained in step (2) under stirring at 800 r / min, and continue stirring and mixing for 15 minutes to obtain an adhesive for in-mold decoration.

Embodiment 2

[0054] A preparation method of adhesive glue for in-mold decoration, said preparation method comprising the following steps:

[0055] (1) 10% propylene glycol methyl ether acetate, 40% cyclohexanone, and 15% tetramethylbenzene are mixed to obtain a mixed solvent, and 20% tertiary hydroxychloride resin and 10% acrylic acid are added to the mixed solvent under stirring at 1200r / min Resin, continue to stir 1h, obtain resin solution;

[0056] (2) Add 4% fumed silica to the resin solution obtained in step (1) under stirring at 800r / min, continue stirring for 20min, grind and disperse, and obtain a semi-finished adhesive;

[0057] (3) Add 1% silicone defoamer to the adhesive semi-finished product obtained in step (2) under stirring at 1200r / min, and continue stirring and mixing for 20min to obtain an adhesive for in-mold decoration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com