Cleaning agent for printing ink

A printing ink and cleaning agent technology, which is applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of long cleaning time and poor effect, and achieve less human damage, simple formula, and improved moisturizing and water retention time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The components of the cleaning agent for printing ink of the present invention are calculated in parts by weight: 3 parts of sodium methyl cocoyl taurate, 2 parts of Span, 1 part of butyl methacrylate, 5 parts of tea saponin, tung seed oil 4 parts, 3 parts of lauryl betaine, 5 parts of seaweed mud powder, 1 part of potassium humate, 15 parts of water.

[0015] The preparation method of the printing ink cleaning agent is as follows: first, heat water to 70°C, then add the raw materials into the reaction kettle at 18°C, stir at 500r / min for 2 minutes, and then heat up to 85°C , after stirring at 50r / min for 10 minutes, naturally cool to room temperature, filter twice, and combine the filtrates to obtain a cleaning agent for printing ink.

Embodiment 2

[0017] The components of the printing ink cleaning agent are calculated in parts by weight: 4 parts of sodium methyl cocoyl taurate, 3 parts of Span, 3 parts of butyl methacrylate, 7 parts of tea saponin, tung seed oil 7 parts, 5 parts of lauryl betaine, 7 parts of seaweed mud powder, 2 parts of potassium humate, 18 parts of water.

[0018] The preparation method of the printing ink cleaning agent is as follows: first, heat water to 75°C, then add the raw materials into the reaction kettle at 20°C, stir at 550r / min for 3 minutes, then heat up to 88°C , after stirring at 62r / min for 13 minutes, naturally cool to room temperature, filter twice, and combine the filtrates to obtain the printing ink cleaning agent.

Embodiment 3

[0020] The components of the printing ink cleaning agent are calculated in parts by weight: 5 parts of sodium methyl cocoyl taurate, 4 parts of Span, 2 parts of butyl methacrylate, 9 parts of tea saponin, tung seed oil 6 parts, 4 parts of lauryl betaine, 10 parts of seaweed mud powder, 3 parts of potassium humate, 20 parts of water

[0021] The preparation method of the printing ink cleaning agent is as follows: firstly, heat the water to 81°C, then add the raw materials into the reaction kettle at 23°C, stir at 600r / min for 3 minutes, and then heat up to 91°C , after stirring at 70r / min for 18 minutes, naturally cool to room temperature, filter twice, and combine the filtrates to obtain a cleaning agent for printing ink.

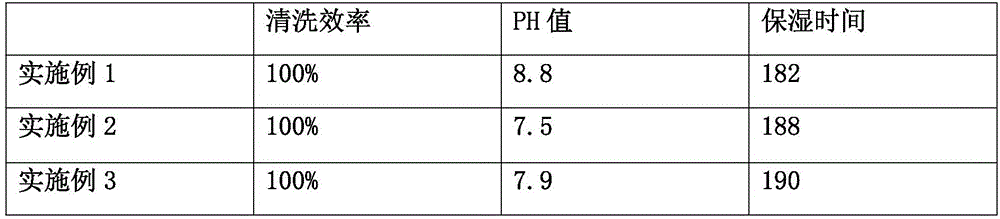

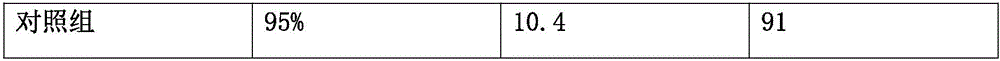

[0022] The cleaning agent prepared by the embodiment of the present invention 1-3 is compared with the cleaning agent without adding seaweed mud in the following table:

[0023]

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com