Polymer-based micro/nano composite material powder and preparation method thereof

A nano-composite material and polymer technology, applied in the polymer field, can solve the problems of inability to solve the problem of inorganic nano-particle dispersion, the comprehensive performance of sintered products cannot meet the expected requirements, etc., and achieves the promotion of application development, easy large-scale production, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a polymer-based micro / nano novel composite material powder suitable for selective laser sintering, comprising the following steps:

[0027] A. Grinding: Grind 13-98 parts of polymer, 1-85 parts of inorganic functional particles, and 1-2 parts of antioxidant through a solid-phase force chemical reactor, and control the cooling water temperature during the grinding process 5-30°C, milling pressure 10-50MPa, milling speed 10-1000rpm, milling times 5-20 times; preferred circulating water temperature 5-20°C, milling pressure 25-50MPa, milling speed 100-500rpm, and the number of grinding times is 5-15 times.

[0028] B. Granulation: Melt and extrude the compound powder obtained by grinding in a screw extruder, optimize the extrusion temperature and speed according to the characteristics of the material itself, and then granulate;

[0029]C. Cryogenic crushing: put the extruded particles into the silo of the cryogenic crushing equipment, and use liquid ...

Embodiment 1

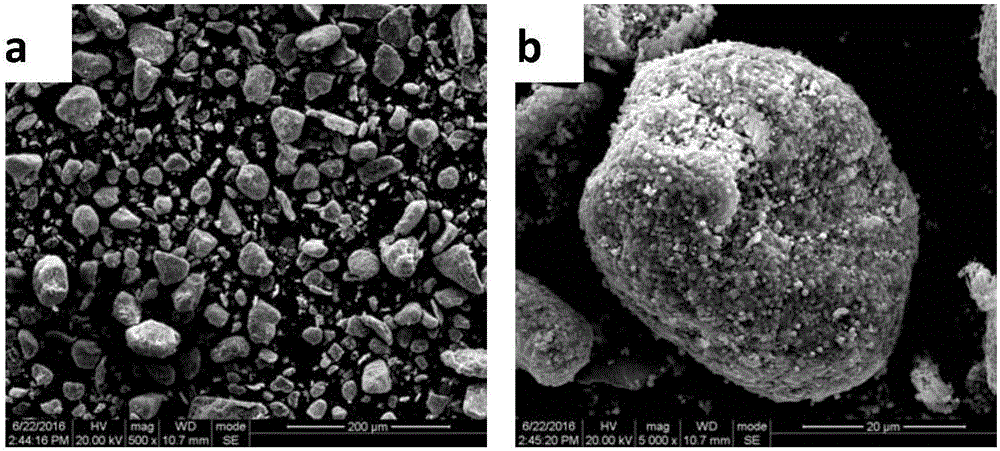

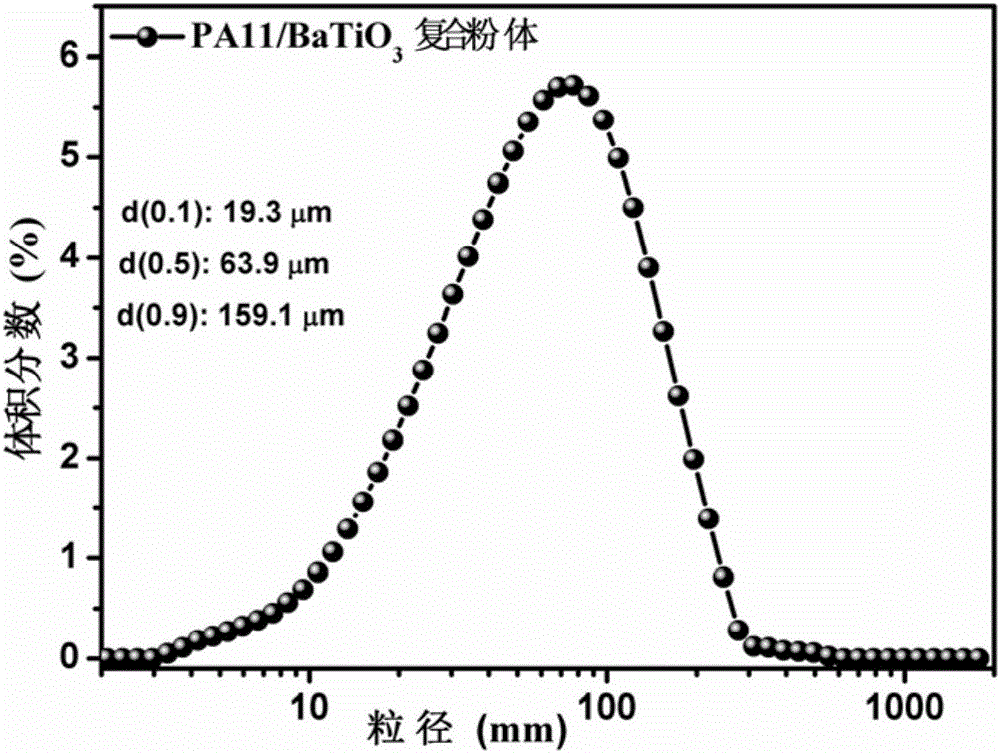

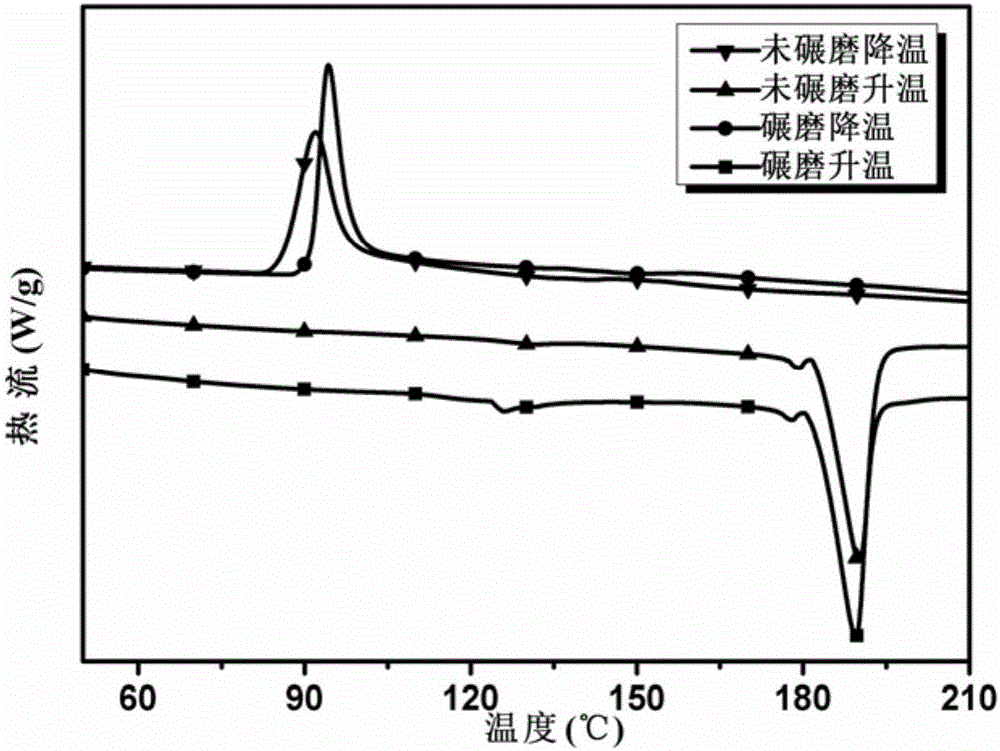

[0041] PA11 / BaTiO 3 Piezoelectric nanocomposite material: first, 130g of nylon 11 (PA11) with a particle size of 2 to 5mm, BaTiO 3 850g of piezoelectric nanopowder particles, with an average particle size of 500nm, and 18g of 1,3,5-trimethyl-2,4,6(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 2, Add 2 g of 2-ethylene bis(4,6-di-tert-butylphenyl) fluorophosphite into the opened disc-shaped mechanochemical reactor through the feeding port, and control the temperature of cooling circulating water at 25°C during the milling process , the grinding pressure is 25MPa, the grinding speed is 500rpm, after 10 times of grinding, PA11 / BaTiO 3 Piezoelectric nanocomposite material powder; the composite material powder obtained by grinding is melted and extruded in a twin-screw extruder, the extrusion temperature is 190-210°C, the extrusion speed is 80rpm, and then granulated to obtain a particle size of 2- 5mm composite material particles; the extruded particles are added to the cryogenic cr...

Embodiment 2

[0045] PA12 / CNTs conductive nano-composite material: First, 980g of nylon 12 (PA12) with a particle size of 2-5mm, 10g of CNTs powder particles, a length of 1.5μm, a diameter of 9.5nm and 2,6-di-tert-butyl-4-methyl- 14g of phenol and 46g of tetrakis(2,4-di-tert-butylphenyl)-46g were added to the opened disc-shaped mechanochemical reactor through the feeding port. During the grinding process, the cooling circulating water temperature was controlled at 25°C and the grinding pressure was 15MPa , the milling speed is 700rpm, and after 6 times of milling, a uniformly mixed PA12 / CNTs conductive nanocomposite powder is obtained; the composite powder obtained by milling is melted and extruded in a twin-screw extruder, and the extrusion temperature 180-200°C, extrusion speed 80rpm, and then granulated to obtain composite material particles with a particle size of 2-5mm; the extruded particles were added to the cryogenic crushing equipment to be crushed and classified and collected by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com