Modified phenolic resin material and application thereof

A phenolic resin and modification technology, applied in the field of materials, can solve the problems of adverse effects on the environment and human health, inability to fully utilize resources, unfavorable cost reduction and efficiency increase, etc., achieve good sound absorption and sound insulation performance, simple manufacturing process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

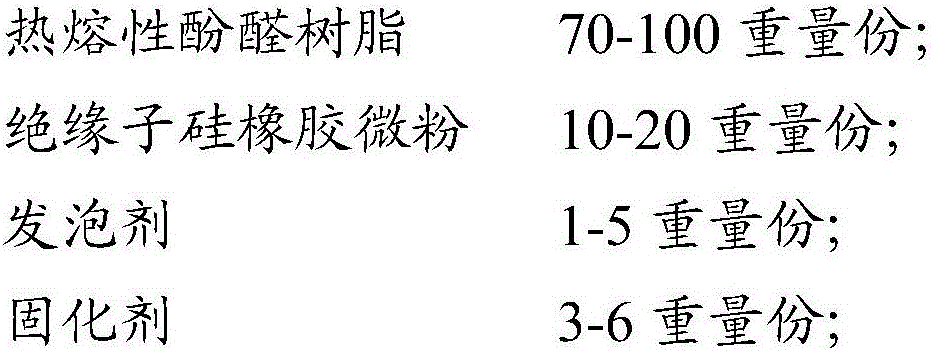

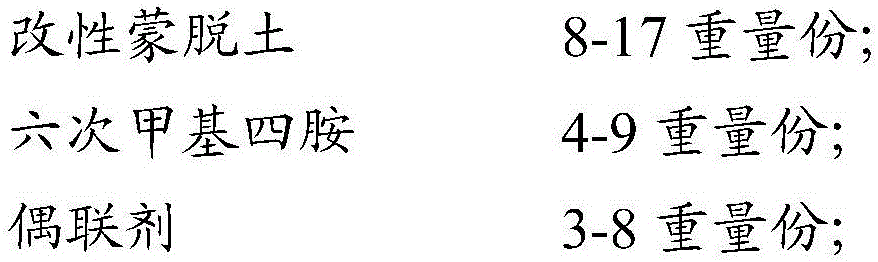

Method used

Image

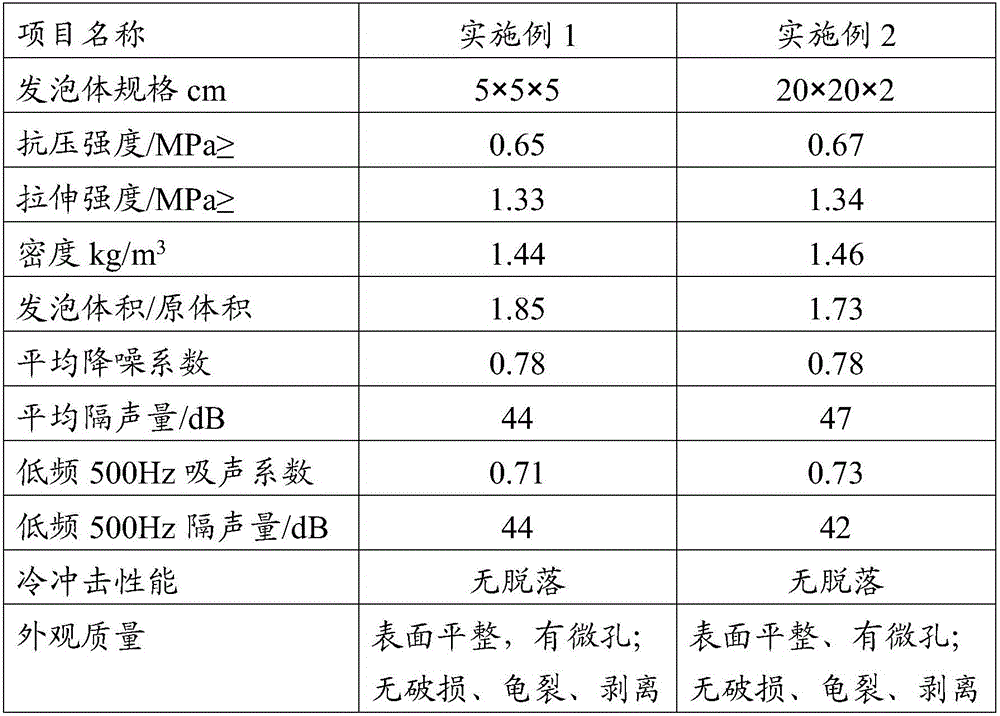

Examples

Embodiment 1

[0043] The preparation method of preparing modified phenolic resin material of the present invention is as follows:

[0044] 1) Get 40g of phenol, 40g of formaldehyde, and 15g of sodium hydroxide, wherein the sodium hydroxide is configured into an aqueous solution with a mass fraction of 30%, and the three are mixed and added to a three-necked flask with an existing magnetic rotor. Heat to about 95°C within 20 minutes and react at a constant temperature for 30 minutes, then cool down to 75°C. At this time, the mixture is viscous, and its viscosity is measured in the range of 200-300Pa·s (measured at 20°C) to obtain a mixture;

[0045] 2) Add 15g of insulator silicon rubber micropowder to the mixture obtained in step 1) and mix them evenly under magnetic stirring conditions, then add 9g of modified montmorillonite; simultaneously add 10-20g of formaldehyde and 5g of sodium hydroxide to quickly Stir well, adjust the reaction temperature to about 85°C, measure the viscosity of th...

Embodiment 2

[0049] The preparation method of preparing modified phenolic resin material of the present invention is as follows:

[0050] 1) Get 200g of phenol, 20g of formaldehyde, and 60g of sodium hydroxide, wherein the sodium hydroxide is configured into an aqueous solution with a mass fraction of 30%, and the three are mixed and added to a three-necked flask placed with a magnetic rotor, and heated at a constant temperature under the action of a mechanical stirrer. React in a water bath at 90°C for 35 minutes, change the constant temperature condition to 75°C, and measure the viscosity of the mixed thick product in the range of 200-300Pa·s (measured at 20°C) (when the viscosity does not meet the conditions, continue to heat up at about 95°C response, followed by measurement);

[0051] 2) To the mixture obtained in step 1), add 70 g of insulator silicon rubber micropowder successively under magnetic stirring conditions and mix evenly, then add 40 g of modified montmorillonite; simultan...

Embodiment 3

[0057] Determination of free formaldehyde content in resin: Accurately weigh 3g of commercially available phenolic resin material (marked as comparative example) and Example 1 and Example 2 respectively, put them into a beaker, add 25mL of ethanol and 25mL of distilled water and stir to mix evenly. Add 0.05 mol / L hydrochloric acid dropwise under stirring until pH = 4.0 (accuracy is 0.1), add 20 mL of 10% mass fraction of hydroxylamine hydrochloride solution, continue stirring for 5 min, and titrate to pH with 0.1 mol / L sodium hydroxide standard solution =4.0, while doing a blank experiment, the content of free formaldehyde in the phenolic resin can be calculated.

[0058] The formula is as follows:

[0059] X=C×(V-V 0 )×(0.03003) / M×100%

[0060] In the formula: X——the content of free formaldehyde in phenolic resin, %;

[0061] V——the volume of sodium hydroxide standard solution consumed by the sample, the mL sample is the comparison group and embodiment 1 and embodiment 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com