Polymeric acid cross-linking agent, preparation method and sealant with cross-linking agent

A cross-linking agent and sealant technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of increasing cross-linking density, crystallization, bubbles, etc., and achieve reaction The effect of mild conditions and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

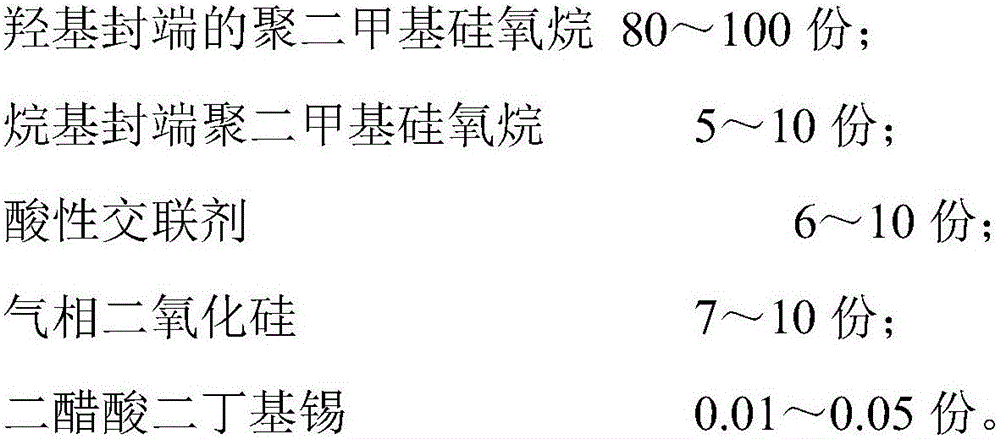

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a kind of preparation method of polyacidic crosslinking agent, comprises the following steps:

[0027] In parts by mass, add 100 parts of alkyl triacetoxy and 1 to 5 parts of aluminum acetate into the reaction kettle and mix evenly, heat up to 70-90°C and react for 8-10 hours. The acetic anhydride generated by the reaction is removed under the conditions of a pressure of -0.098MPA and a temperature of 90°C to obtain a polymerized alkyltriacetoxysilane.

[0028] The alkyltriacetoxysilane in the embodiment of the present invention is methyltriacetoxysilane, ethyltriacetoxysilane, propyltriacetoxysilane or vinyltriacetoxysilane.

[0029] Due to the high hydrolysis activity of alkyltriacetoxysilane, direct water hydrolysis is easy to cause local polycondensation into high polymers, so it is necessary to add a large amount of acetic acid to dilute. The boiling point of alkyltriacetoxysilane is close to that of alkyl triacetox...

Embodiment 1

[0039] Add 440 grams of methyltriacetoxysilane and 4.4 grams of aluminum acetate into a three-necked flask with a capacity of 1 L, mix well and react at a temperature of 90°C for 8 hours, filter out the aluminum acetate, and use negative pressure to remove acetic anhydride to obtain Polymerized alkyltriacetoxysilane (hereinafter referred to as product 1).

[0040] After chromatographic analysis, the contents of each component in Product 1 are: 0.5% acetic acid, 1.5% acetic anhydride, 15.9% methyltriacetoxysilane, 60.4% methyltriacetoxysilane dimer, methyltriacetoxysilane Silane trimer 19.3%.

Embodiment 2

[0042] Add 440 grams of ethyltriacetoxysilane and 22 grams of aluminum acetate into a three-necked flask with a capacity of 1 L, mix well and react at a temperature of 70°C for 10 hours, then filter to remove aluminum acetate, and use negative pressure to remove acetic acid anhydride to obtain polymerized alkyltriacetoxysilane (hereinafter referred to as product 2).

[0043] After chromatographic analysis, it can be known that the content of each component in product 2 is: 0.6% of acetic acid, 1.8% of acetic anhydride, 14.3% of ethyl triacetoxysilane, 61.4% of ethyl triacetoxysilane dimer, ethyl triacetyl Oxysilane trimer 18.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com