Ultrahigh-density high-strength polyurethane spray-coating material, and preparation method and application thereof

An ultra-high density, spraying material technology, applied in the field of polyurethane, can solve the problems of unsatisfactory use effect, low construction latitude, poor thermal insulation performance, etc., and achieve the effect of improving product competitiveness, convenient production and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

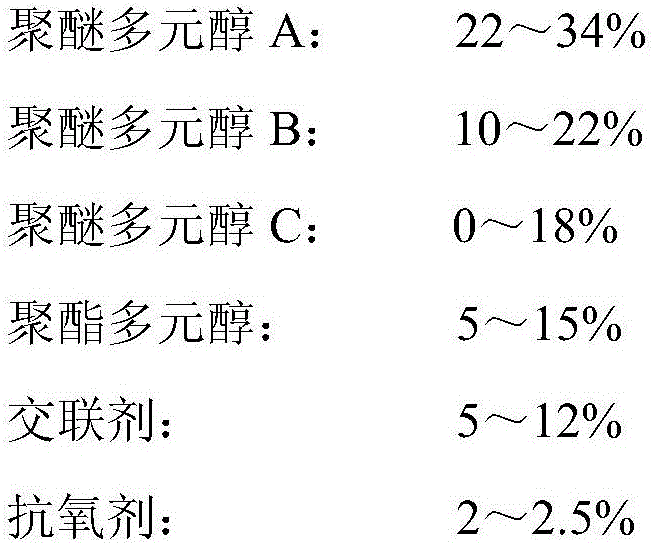

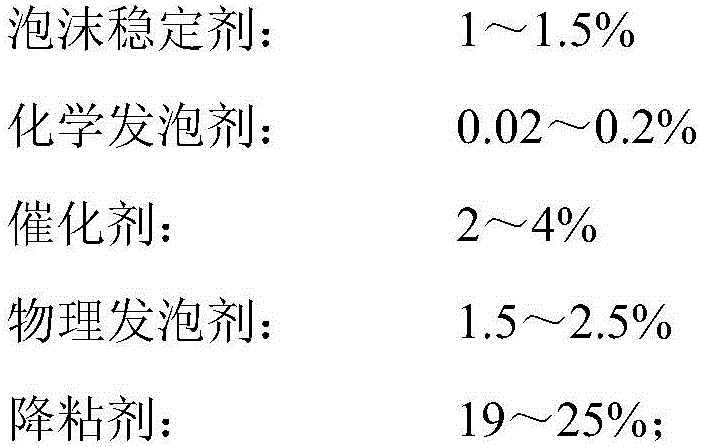

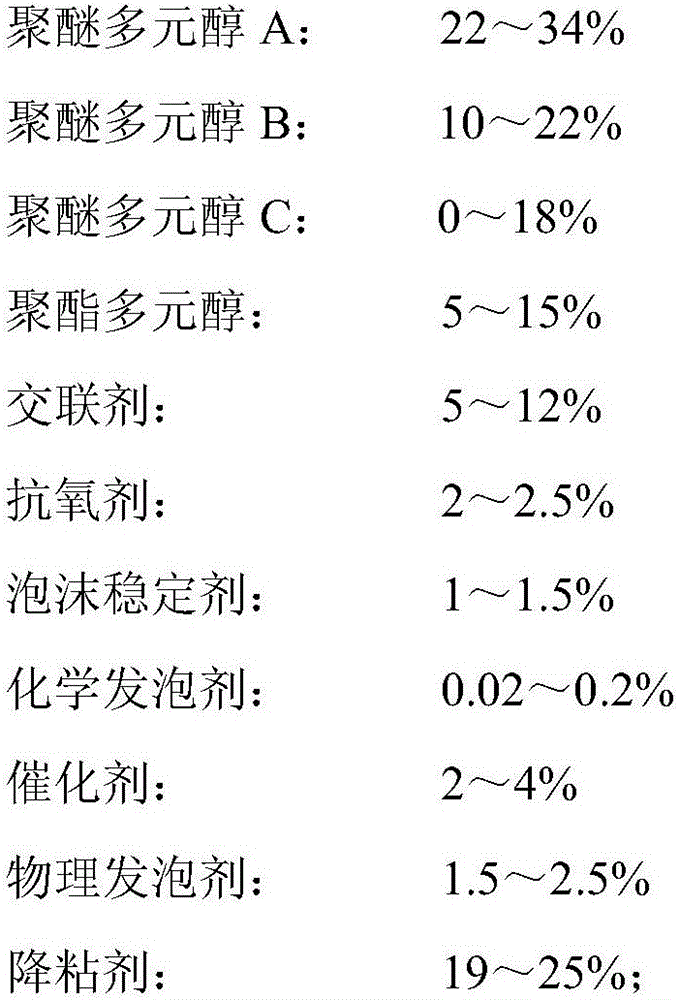

Method used

Image

Examples

Embodiment 1

[0034] Prepare component A in a 1-ton reaction vessel, and weigh: polyether polyol A (Shandong Yinuowei New Material Co., Ltd. YNW-6205): 50 parts; polyether polyol B (Shanghai Dongda Chemical Co., Ltd. SD-7100): 30 parts; polyester polyol (preferably Stepan Chemical Co., Ltd. 2412): 20 parts; crosslinking agent (SINOPEC 1,4BG): 8 parts, antioxidant (Taiwan double bond 1135): 3 parts; silicone oil H3315 (Zhongdong County): 2 parts; chemical blowing agent H 2 O: 0.2 parts; pentamethyldiethylenetriamine (PC-5) 1 part; 33% triethylenediamine solution (A33): 2 parts; dibutyltin dilaurate (T-12): 0.4 parts; 1 , 3,5-tris(dimethylaminopropyl)hexahydrotriazine (PC-41): 1 part; viscosity reducer (TEP, Zhangjiagang Yarui Chemical Co., Ltd.): 30 parts; Ecomate: 3 parts. Add the weighed polyether polyol, polyester polyol, crosslinking agent, antioxidant, foam stabilizer, chemical foaming agent, catalyst, viscosity reducer, physical foaming agent into the reactor in sequence, Stir at roo...

Embodiment 2

[0040] Prepare component A materials in a 1-ton reaction vessel, and weigh them separately: polyether polyol A (YNW-6207 of Shandong Yinuowei New Material Co., Ltd.): 40 parts; polyether polyol B (Jurong Ningwu New Material Co., Ltd.) Co., Ltd. 4110HN): 20 parts; polyether polyol C (Shandong Yinuowei New Material Co., Ltd. YNW370S): 30 parts; polyester polyol (Optimized Stepan Chemical Co., Ltd. 2412): 10 parts; crosslinking agent (Sinopec 1,4BG): 20 parts, antioxidant (Taiwan double bond 1135): 4 parts; silicone oil H3315 (Zhongshan Dongjun): 2 parts; chemical foaming agent H 2 O: 0.05 parts; pentamethyldiethylenetriamine (PC-5) 0.5 parts; 33% triethylenediamine solution (A33): 2 parts; dibutyltin dilaurate (T-12): 0.05 parts; 1 , 3,5-tris(dimethylaminopropyl)hexahydrotriazine (PC-41): 1 part; Viscosity reducer (Zhangjiagang Yarui Chemical Co., Ltd. TEP): 40 parts; Ecomate: 3 parts. Add the weighed polyether polyol, polyester polyol, crosslinking agent, antioxidant, foam sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com