High-flame-retardancy polyurethane gas hole sealing material for coal mine and preparation method of high-flame-retardancy polyurethane gas hole sealing material

A sealing material and high flame retardant technology, applied in the field of polyurethane, can solve the problems of difficult to meet the flame retardant requirements and high addition amount, and achieve the effects of good adhesion, good flame retardant performance and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

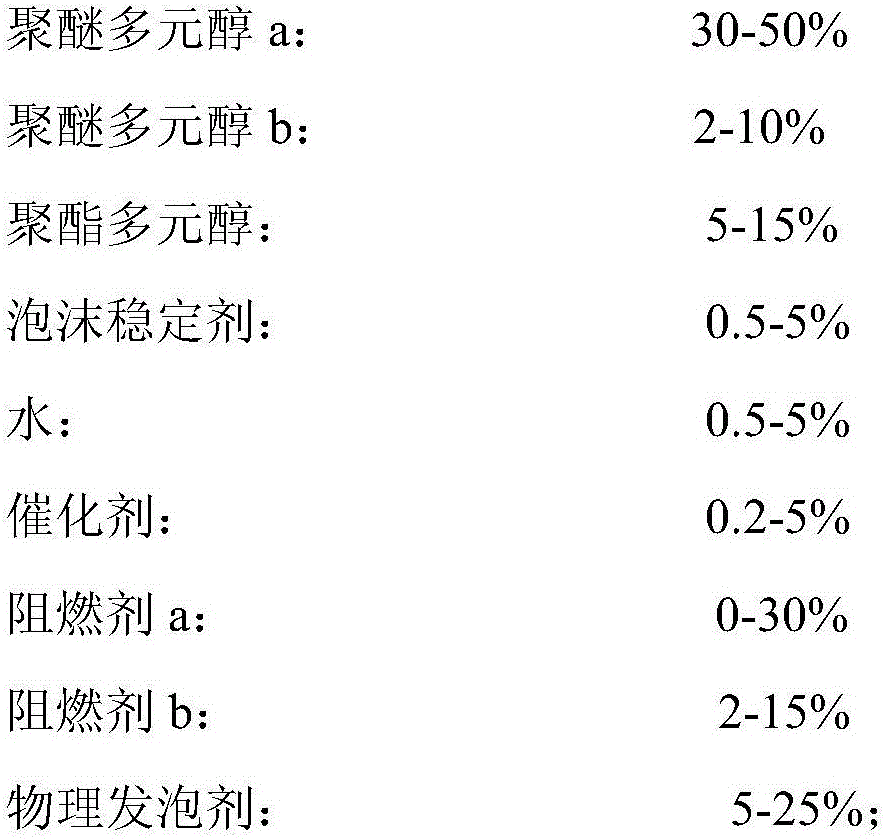

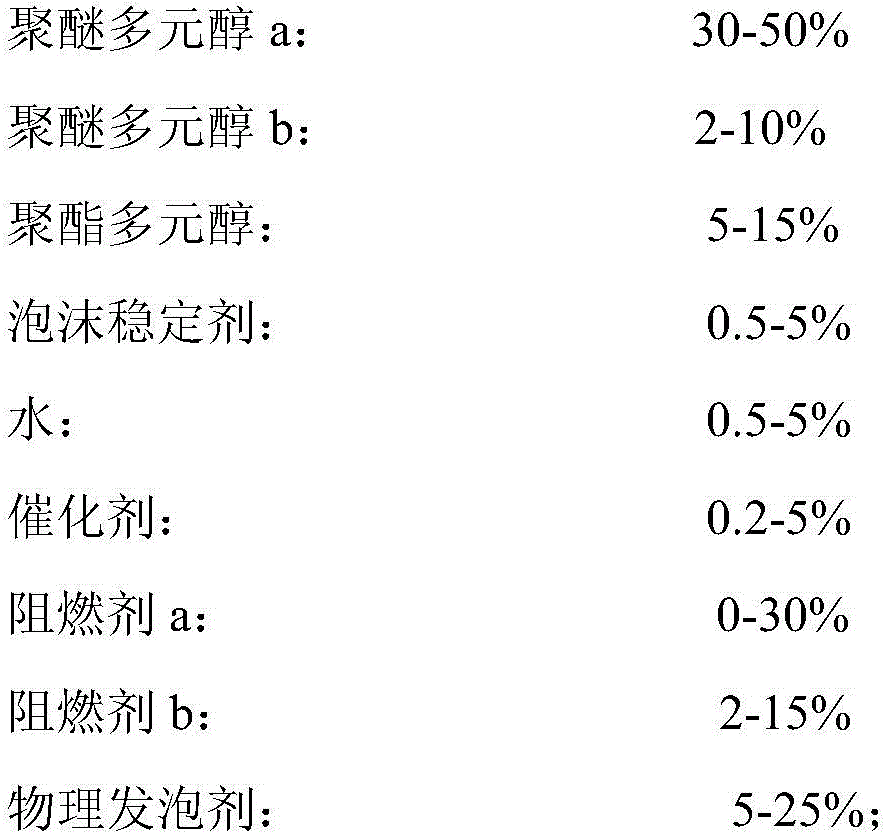

Method used

Image

Examples

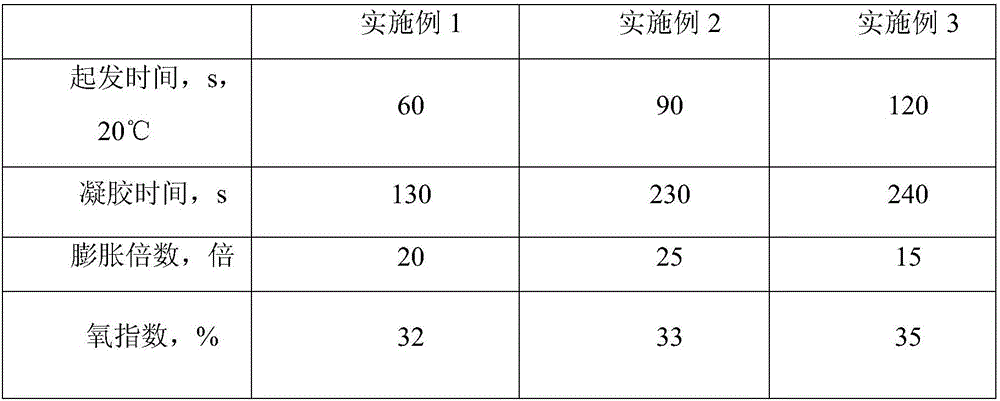

Embodiment 1

[0029] (1) Prepare 100 kg of component A material, respectively weigh 35 kg of polyether polyol (SA460, Bluestar Dongda), 5 kg of polyether polyol (DL400, Bluestar Dongda), polyester polyol (B175 , a Novel) 10 kg, foam stabilizer (L6950, Momentive, USA) 2 kg, water 1.5 kg, N,N-dimethylcyclohexylamine 0.2 kg, N,N-dimethylbenzylamine 0.8 kg, 1 kg of Dabco TMR-2 (U.S. Air Chemicals), 20 kg of TCPP, 4.5 kg of expanded graphite flame retardant (LM8089, Qingdao Lianmei), 20 kg of fluorodichloroethane, and the weighed polyether polyol , polyester polyol, water, foam stabilizer, catalyst, and flame retardant are put into a mixing tank and stirred, then a physical foaming agent is added, and stirred evenly at room temperature. After sampling and testing pass, it can be loaded into barrels.

[0030] (2) Use 44V20 (Bayer) for the preparation of component B, 100 kg.

[0031] The components A and B are mixed according to the weight ratio of A:B=100:100 to prepare the highly flame-retardan...

Embodiment 2

[0033] (1) Prepare 100 kg of component A material, weigh 42 kg of polyether polyol (450L, Bluestar Dongda), 7.5 kg of polyether polyol (DL1000, Bluestar Dongda), polyester polyol (B503 , Novo) 14 kg, foam stabilizer (B8545, Evonik Degussa) 3 kg, water 2 kg, N,N-dimethylbenzylamine 0.6 kg, Dabco TMR-2 (American Air Chemicals) 0.7 kg , DBU (1,8-diazacycloundecene) 0.2 kg, expanded graphite flame retardant (LM8089, Qingdao Lianmei) 12 kg, fluorodichloroethane 18 kg, weighed polyether Polyols, polyester polyols, water, foam stabilizers, catalysts, and flame retardants are put into a mixing tank and stirred, then a physical foaming agent is added, and stirred evenly at room temperature.

[0034] (2) Use PM200 (Yantai Wanhua) for the preparation of component B, 100 kg.

[0035] The components A and B are mixed according to the weight ratio of A:B=100:100 to prepare the highly flame-retardant polyurethane gas sealing material for coal mines.

Embodiment 3

[0037] Prepare 100 kg of component A material, weigh 38.3 kg of polyether polyol (YNW4110, Yinuowei new material), 9 kg of polyether polyol (MN1000, Bluestar Dongda), and polyester polyol (PS3152, Si Taipan) 8 kg, foam stabilizer (L6952, American Momentive) 1 kg, water 0.8 kg, N,N-dimethylbenzylamine 0.4 kg, Dabco TMR-2 (American Air Chemicals) 0.5 kg, TEP 25 kg, Expanded graphite flame retardant (LM8089, Qingdao Lianmei) 10 kg, 1 fluorodichloroethane 7 kg, weighed polyether polyol, polyester polyol, water, foam stabilizer, catalyst, flame retardant Put the agent into the mixing tank and stir, then add the physical foaming agent, stir evenly at room temperature, after the sampling test is qualified, it can be loaded into barrels.

[0038] (2) To prepare component B, use M20S (BASF), 100 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com