Compound interface layer modified C/C composite material as well as preparation method and application thereof

A composite material and interface layer technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of friction material wear failure, friction surface stress concentration, weak interface bonding, etc., to achieve improved interface bonding, mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

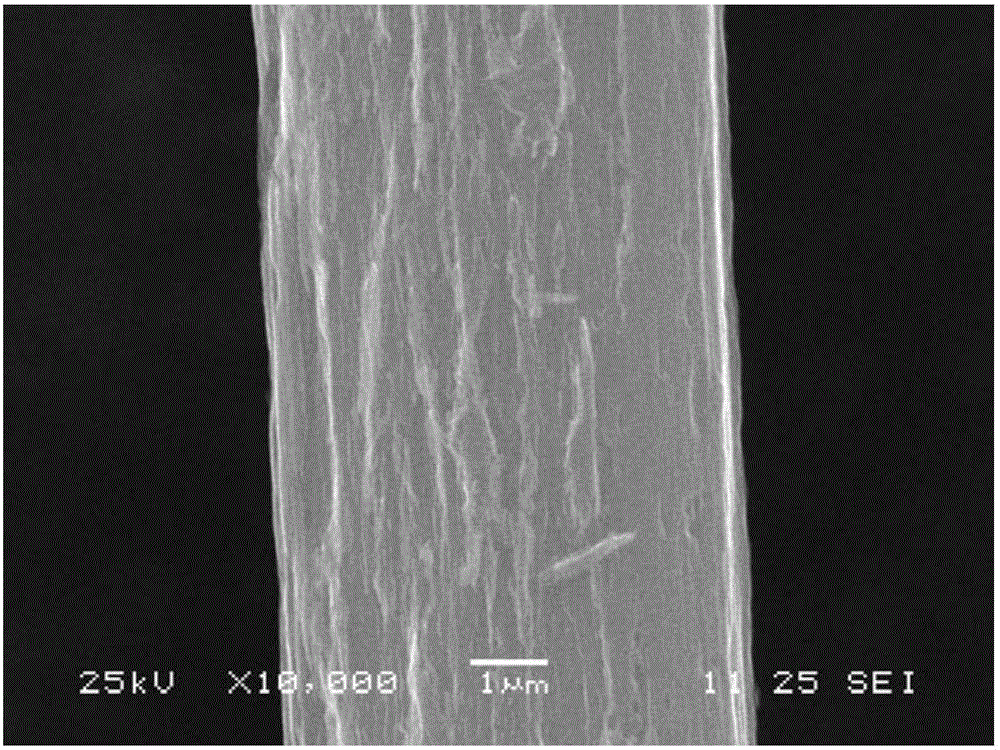

[0063] (1) Soak the PAN-based T700 (12K) carbon cloth produced by Toray in Japan in 5% boric acid aqueous solution for 24 hours, keep the solution temperature at 80°C, and then dry it at 100°C for 4 hours.

[0064] (2) Arrange the carbon treated in step (1) in a graphitization furnace for pre-graphitization treatment, the graphitization temperature is 2500° C., and the holding time is 4 hours.

[0065] (3) Prepare a mixed solution with epoxy resin, alcohol, and nano-silicon carbide fibers in a mass ratio of 25:25:3, place the mixed solution in a water bath for heating at 65°C, and stir with a magnetic stirrer at the same time , to obtain a homogeneous mixed solution.

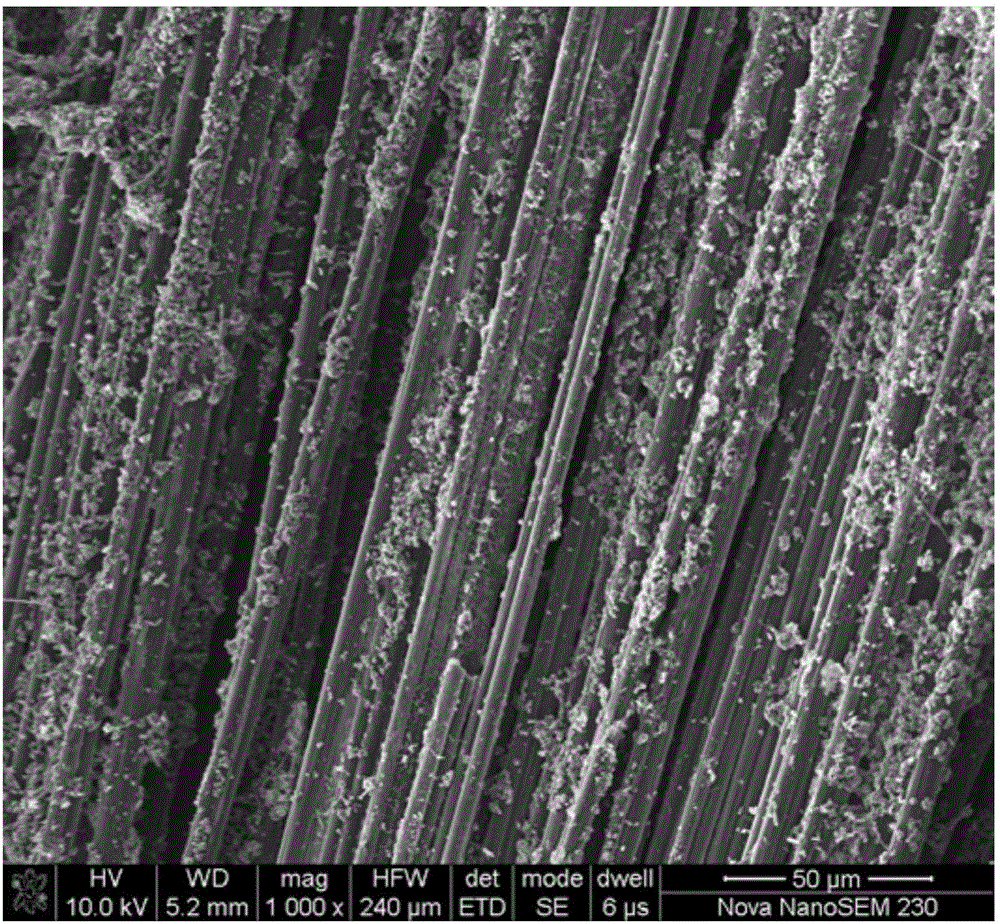

[0066] (4) Put the carbon cloth treated in step (2) into the mixed solution prepared in step (3) and soak for 40 minutes, and perform ultrasonic vibration, so that the nanofibers are evenly covered on the surface of the carbon fibers;

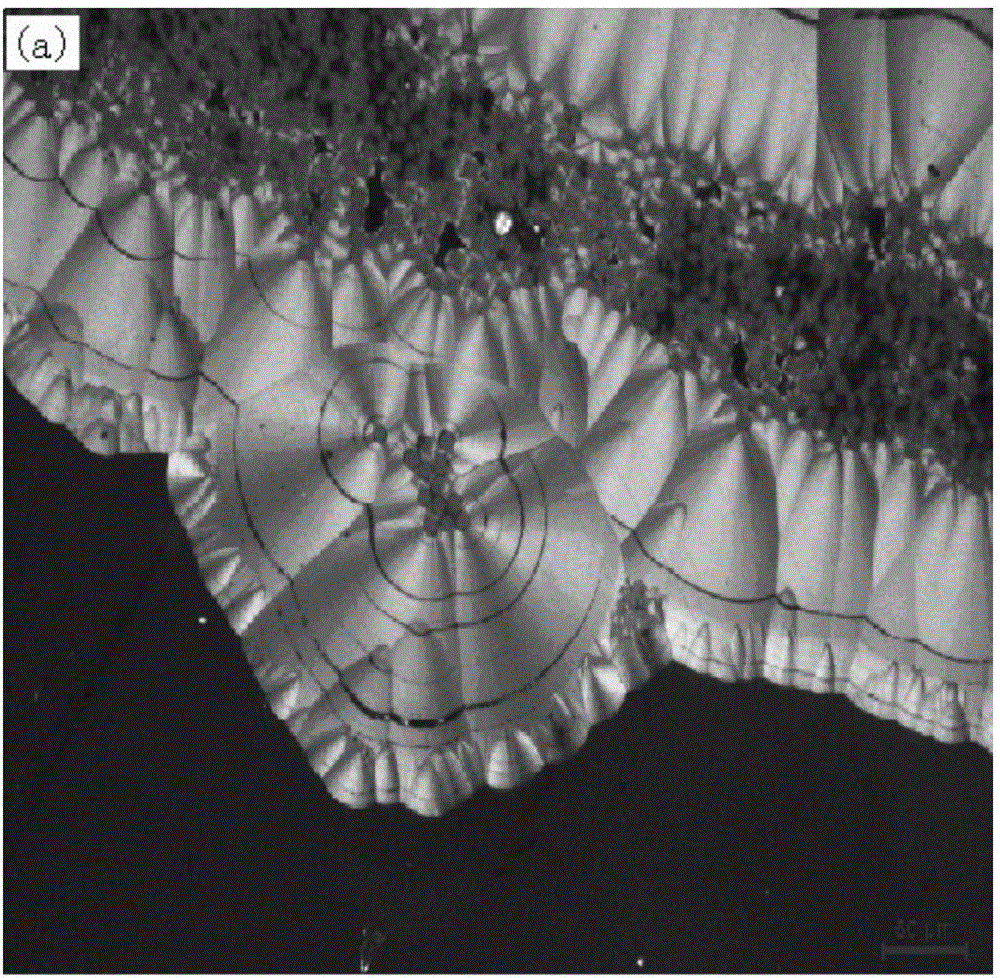

[0067] (5) Laminate the carbon cloth treated in step (4) in a self-made jig...

Embodiment 2

[0071] (1) Soak the PAN-based T700 (12K) carbon cloth produced by Toray in Japan in 7% boric acid aqueous solution for 28 hours, keep the temperature of the solution at 80°C, and then dry it at 110°C for 3 hours.

[0072] (2) Arrange the carbon treated in step (1) in a graphitization furnace for pre-graphitization treatment, the graphitization temperature is 2600° C., and the holding time is 4 hours.

[0073] (3) Prepare a mixed solution with epoxy resin, alcohol, and nano-silicon carbide fibers in a mass ratio of 25:25:5, place the mixed solution in a water bath for heating at 80°C, and stir with a magnetic stirrer at the same time , to obtain a homogeneous mixed solution.

[0074] (4) Put the carbon cloth treated in step (2) into the mixed solution prepared in step (3) and soak for 50 minutes, and perform ultrasonic vibration, so that the nanofibers evenly cover the surface of the carbon fibers;

[0075] (5) Laminate the carbon cloth treated in step (4) in a self-made jig t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com